Work In Process (WIP) Tracking

From Raw Material to Finished Product

Work in Process (WIP) tracking refers to tracking each item in production throughout the entire manufacturing process to ensure efficiency, accuracy, and traceability.

In many facilities, WIP tracking is still completed by hand, using spreadsheets and manual data entry; however, automated WIP tracking not only saves times and reduces errors, but it also provides real-time visibility into the flow of materials throughout production.

The foundation for automated WIP tracking is reliable barcode reading. Keep reading to learn about code reading solutions for WIP tracking or contact us to discuss your specific application.

Visibility into Every Step of the Process

Tracking items from raw materials to finished products provides a wide variety of benefits including enabling manufacturers to:

- Know the location and status of customer orders during production to ensure on-time shipment and delivery.

- Track availability of raw materials inventory in real time to facilitate restocking and keep production levels on target.

- Accurately track scrapped or reworked parts to identify areas for process improvement.

- Track finished products back to the original materials for quick and accurate recall of defective products.

These, among other capabilities, enable manufacturers to increase profitability and remain competitive in their industries by increasing efficiency, reducing waste, and allowing for accurate, real-time identification of defects and bottlenecks.

Track Inventory and Origin of Materials

- A product's quality depends on the integrity of its parts, so tracking raw materials is critical.

- Scanning and tracking received goods and raw materials provides manufacturers with valuable data that can be used in case an issue is discovered during quality inspections or product recall.

- If a defect is identified with a particular part on a product, insight into the origin of the defective materials can help manufacturers isolate affected batches and prevent future defects.

- In addition to facilitating quality control and recalls, tracking incoming goods also enables better inventory management to ensure necessary parts are restocked in a timely manner.

Improve Efficiency and Reduce Waste

- Tracking individual components throughout product helps manufacturers improve efficiency, reduce waste, and achieve lean manufacturing goals.

- For example, manufacturers can easily determine which parts are scrapped most often and where the waste is occurring. This allows manufacturers to identify solutions to reduce waste and analyze the success of those solutions over time.

- Scanning components and products at each stage of production also enables manufacturers to track the time between each stage to identify and reduce bottlenecks in production and facilitate staffing and resource allocation.

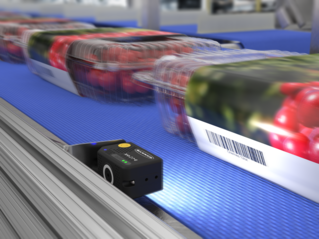

Ensure Accurate, Timely Order Fulfillment

- Accurate and timely shipments are critical. Missed ship dates, incorrect, or incomplete orders can cause delays throughout the supply chain and decrease customer satisfaction.

- Order, shipping, and tracking information is embedded in separate 1D and 2D barcodes printed every box in a shipment. This information must be verified before the boxes are loaded onto a pallet and the shipment leaves the facility.

- As packages travel at high speeds on the line to the palletizer, an ABR 7000 barcode reader with a liquid lens autofocus verifies each barcode printed on the label.

- Algorithms programmed into the barcode reader locate each barcode, extract the data, and verify that the barcodes match the criteria established during inspection setup.

- This information is then sent over an Ethernet connection to the management system which records the data.

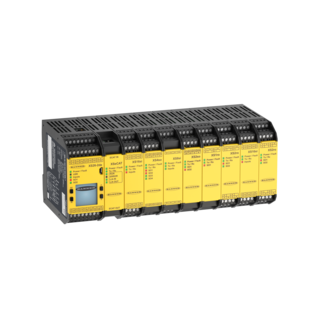

Imager-Based 1D and 2D Barcode Reader

ABR 7000 barcode readers offer superior decoding capability and are in multiple resolutions and a wide range of lens options.

- ABR 7000 barcode readers provide advanced features including extended reading distance and field-of-view, advanced lighting, a variety of focal lengths (including autofocus) and the ability to link multiple readers together.

- Powerful decoding capability to read even difficult 1D and 2D codes, including DPM and low contrast codes

- Quick configuration with on-board push buttons or a PC using Barcode Manager, Banner’s free operating software

- Integrated LED lighting and easy focus adjustment in one package for maximum application flexibility

- Versatile lens options are available to simplify setup and configuration, including a software adjustable autofocus which easily adapts to changes in reading distance

- Factory communication options include Ethernet and serial for integration on the manufacturing floor

- Embedded web server interface for monitoring images and statistics over any network

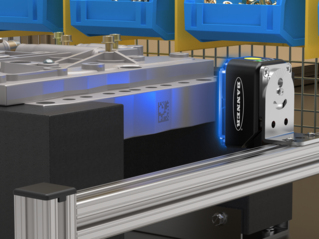

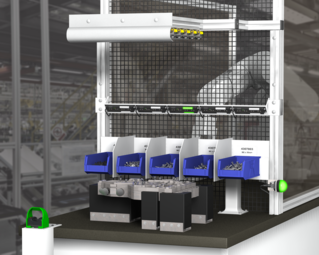

Imager-Based 1D and 2D Barcode Reader

iVu BCR Series barcode readers combine powerful decoding capabilities with ease-of-use to solve challenging traceability applications. These versatile barcode readers are available with a range of lens, lighting, and user interface options.

- Reads a broad range of 1D and 2D barcodes, including damaged, distorted, and other difficult-to-read codes

- Capable of reading multiple barcodes in any orientation in a single inspection

- Setup, manage, and monitor inspections using an integrated touch screen, remote touch screen or PC interface

- Ethernet and serial communication protocols simplify device integration and enable IIoT data collection

- Rugged, IP67-rated housing ideal for tight spaces and industrial environments

- Numerous integrated lighting options simplify installation and optimize contrast

- Interchangeable lenses, including a wide range of standard and C-Mount options to meet the needs of any application

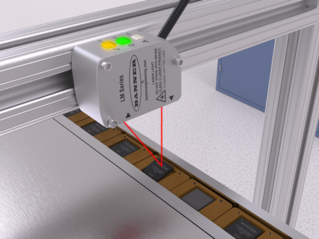

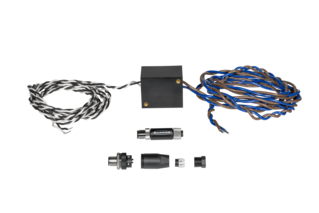

TCNM Series

Laser-Based 1D Barcode Scanner

Able to decode over a dozen commonly used linear barcode symbols, the TCNM sensor provides fast read rates, broad depth of field, and high resolution.

- Reads more than a dozen common linear barcode symbols

- Completes 500 to 1,000 scans per second

- Essential setup and diagnostic operations using SMART-TEACH push button and LED indicators

- Code rebuilding algorithm combines multiple scans to reconstruct damaged code information

- GeniusPlus software and proprietary intra-sensor communication protocol eliminate the need for external multiplexer in multi-sensor setup

- Rugged IP65 housing

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)