Fiber Optic Sensing Technology: What It Is and How It Works

This article explains what fiber optics are and how they work for photoelectric sensing in industrial applications. Keep reading to learn important terminology and the basics of fiber optic systems and assemblies.

What Are Fiber Optics?

Fiber optics are used to transmit light energy over long distances. Optical fibers are thin, transparent strands of optical quality glass or plastic that can be as thin as a strand of hair. In photoelectric sensing, these fibers are used to transmit and/or receive light from the LED of a sensor.

An optical fiber consists of a glass or plastic core surrounded by a layer of cladding material and (for plastic fibers) jacketing. Glass fibers are arranged in bundles, and plastic fibers are usually packaged as monofilaments.

Glass fibers don’t have jacketing. Instead, glass fiber bundles are packaged in sheathing that is usually stainless steel flexible conduit, but may be PVC or some other type of flexible plastic tubing. A protective steel coil can also be used beneath the sheath to protect the fiber bundle.

To learn more, read: When to Use Fiber Optics for Photoelectric Sensing.

Fiber Optic Terms

Core

The thin glass or plastic center of the fiber, where the light travels.

Cladding

The outer optical material surrounding the core that reflects the light back to the core.

Jacketing

A protective layer to protect plastic fiber from damage and moisture.

Types of Fibers

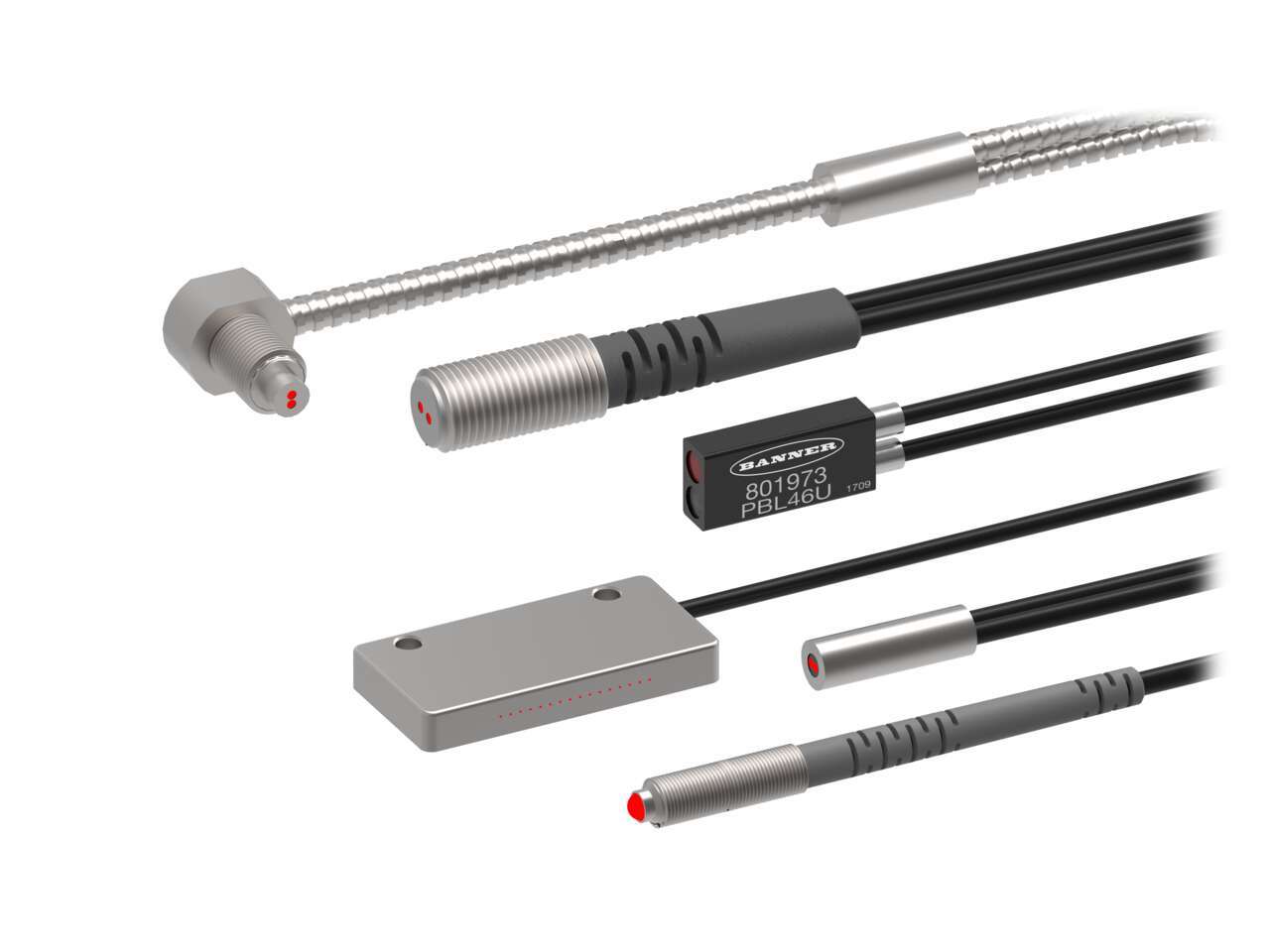

Glass fibers solve sensing applications in challenging environments.

.

Glass Fiber Optics

Glass fiber optics are made up of a bundle of very small (usually about 0.002 inch or 50 micron diameter) glass fiber strands.

A typical glass fiber optic assembly consists of several hundred fibers, protected by a sheathing material, usually a flexible armored cable.

Glass fibers are mostly used in challenging environments, such as applications with high temperature, corrosive substances, or moisture.

Vantage Line high-performance plastic fiber optics from Banner.

Plastic fiber optics

Plastic fiber optics usually have a larger, monofilament core. It is not always bundled, and comes in a single strand of fiber optic material (typically 0.01 to 0.06 inch or 0.25 to 1.5 mm diameter).

Plastic fibers are typically used for more general purpose applications where they can tolerate extreme bending and be cut to length to fit in limited space setups.

How a Fiber Optic System Works

How fiber optics transport light rays can be explained with the optical principle of total internal reflection. This principle states that any ray of light hitting the boundary between the core and the cladding (which have different densities) will be totally reflected, provided that the angle of incidence is less than a certain critical value. The light beam is transported all the way through the tiny fiber by reflection, exiting at the same approximate angle as it entered the fiber.

There is a tendency for the signal to degrade over distance. Attenuation of the signal will occur, depending on the purity of the core material.

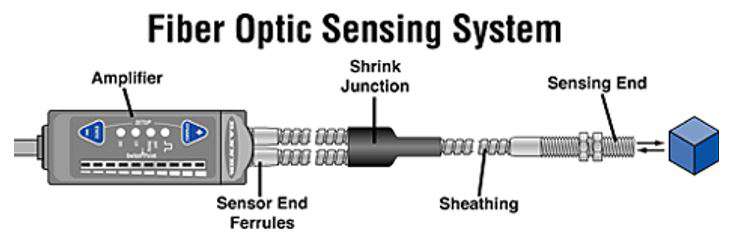

The diagram to the right shows how a fiber optic assembly is connected to an amplifier in a fiber optic sensing system.

Fiber Optic Assemblies

A fiber optic assembly determines the sensing mode. So, once you have chosen the type of fiber you want to use, you would then choose what assembly your application requires.

Individual Fiber Optic Assemblies

Individual fiber optics assemblies simply guide light from an emitter to a sensing location, or from the sensing location back to a receiver. The configuration of the fiber optic assembly determines the sensing mode. Individual assemblies are usually used in pairs for opposed-mode sensing.

Bifurcated Fiber Optic Assemblies

Bifurcated fiber optics conduct the emitted light together with the received light (via two branches consisting of different fibers) within one fiber optic assembly. This allows a single sensor to both illuminate and view an object through the same fiber optic assembly.

If an object appears in front of the sensing end of a bifurcated fiber optic, light from one branch will be reflected off the object and back to the receiver through the other branch. Bifurcated assemblies are typically used in diffuse mode sensing and can also be used in retroreflective-mode sensing.

For More Information

For more information about fiber optic sensing, contact an expert to discuss your specific applciation.