Track and Trace for Product Recall

Mitigate Damages with Accurate, Timely Recalls

An important goal for any manufacturer is to avoid product recall. Recalls are costly, in terms of both actual costs of repair, replacement, or buy-backs as well as the cost of a tarnished brand reputation.

Implementing quality control solutions can help reduce the risk of product defects and safety hazards; however, even the most effective quality control does not eliminate all risk.

Recalls happen, and when they do, it is critical that manufacturers are prepared to respond quickly by identifying affected products and issuing a timely recall to mitigate damages.

When recalls occur, a manufacturer's response can make or break its reputation, and by extension, impact customer loyalty and future profits.

Manufacturers must act quickly and recall all affected products that have already been purchased. In some cases, manufacturers must be able to quickly pull affected inventory from their own shelves, distribution centers, and retail establishments. In other instances, like in many automotive recalls, consumers may need their purchases repaired in a timely manner. Furthermore, to prevent unnecessary costs, manufacturers must avoid inadvertently recalling unaffected products.

Track and trace solutions help manufacturers execute recalls quickly and accurately, so that affected products can be repaired or removed from the market, and the issue can be resolved quickly.

These solutions depend on reliable identification of individual products throughout the supply chain—most commonly by scanning barcodes at every stage from production to purchase. Track and trace solutions are only as reliable as the devices that scan the codes, so selecting the appropriate identification technology is critical.

Track and Trace for Food Safety

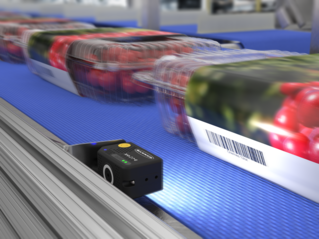

- In food packaging, barcodes are embedded with information specific to each product and production run in order to identify products throughout the supply chain.

- As part of a track and trace program, a packing house verifies product barcodes at multiple points during packaging, creating a record that will allow the company to quickly identify and isolate any product with quality issues in the event of a recall.

- Imager-based barcode readers, like the ABR 3000 from Banner, are capable of decoding the widest range of 1D and 2D barcodes. Deployed along the packaging line, the ABR 3000 verifies that the barcode printed on each package is present, readable, and correct for each production run.

- The information contained in the barcodes is sent via an Ethernet connection to the company’s production management system which records the data for future referrence.

Track and Trace for Automotive Components

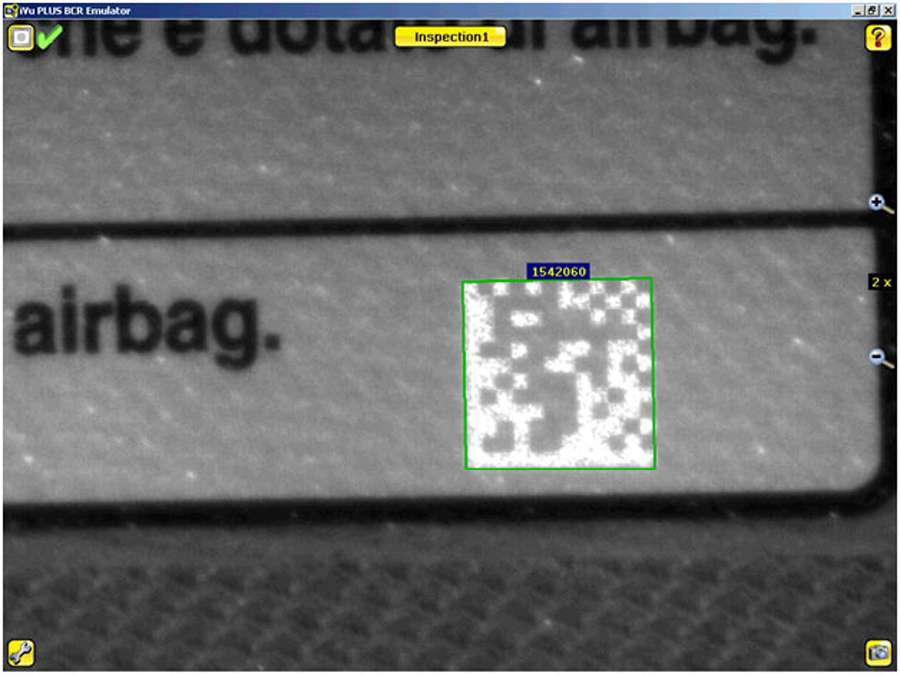

- Many automotive suppliers are incorporating Ultra Violet (UV) barcodes for component traceability and quality control.

- The technology uses UV-based ink that is only visible to the human eye when illuminated with a UV light source. Suppliers can store key informationin a small code printed directly on the component, without affecting design or aesthetics.

- In the event of a recall, codes can be scanned to verify that components were installed and tested in compliance with standards.

- In this application, an iVu BCR barcode reader with a C-mount lens, UV spotlight, and Ethernet capabilities can be used to read invisible 2D Data Matrix codes and send data via EtherNet/IP to a PLC for error proofing and traceability.

Track and Trace for Pharmaceutical Packaging

- Traceability is only effective for facilitating recalls if the correct codes are attached to the correct products. Therefore, validating codes prior to shipment is critical.

- In the pharmaceutical industry, medical supplies are often individually packaged in sealed pouches.

- Before product can be shipped, the barcodes must be validated to ensure that the correct barcode is affixed to the correct product for accurate traceability.

- An imager-based barcode reader validates each barcode and sends data via Ethernet IP to a PLC for future reference in case of recalls.

Imager-Based 1D and 2D Barcode Reader

ABR Series barcode readers offer superior decoding capability to solve the most challenging track and trace applications. They are available in two compact form factors, multiple lighting configurations, a range of resolutions, and numerous lens options.

- Reads a full library of 1D and 2D barcodes

- Two compact form factors rated up to IP67 for use in industrial environments

- Resolutions up to 2MP and multiple lighting configurations and lens focal lengths, including autofocus, to fit any application

- Models for difficult applications, including DPM code reading and polarized windows

- Configures in minutes using on-board push buttons or a PC with fully featured Barcode Manager

- Versatile lens options, including software adjustable autofocus, simplify setup and configuration

- Configure over Industrial Ethernet, Serial and USB to simplify device integration and enable IIoT data collection

- Web interface for monitoring, configuring, and reviewing statistics remotely on any network

Imager-Based 1D and 2D Barcode Reader

iVu BCR Series barcode readers combine powerful decoding capabilities with ease-of-use to solve challenging traceability applications. These versatile barcode readers are available with a range of lens, lighting, and user interface options.

- Reads a broad range of 1D and 2D barcodes, including damaged, distorted, and other difficult-to-read codes

- Capable of reading multiple barcodes in any orientation in a single inspection

- Setup, manage, and monitor inspections using an integrated touch screen, remote touch screen or PC interface

- Ethernet and serial communication protocols simplify device integration and enable IIoT data collection

- Rugged, IP67-rated housing ideal for tight spaces and industrial environments

- Numerous integrated lighting options simplify installation and optimize contrast

- Interchangeable lenses, including a wide range of standard and C-Mount options to meet the needs of any application

TCNM Series

Laser-Based 1D Barcode Scanner

Able to decode over a dozen commonly used linear barcode symbols, the TCNM sensor provides fast read rates, broad depth of field, and high resolution.

- Reads more than a dozen common linear barcode symbols

- Completes 500 to 1,000 scans per second

- Essential setup and diagnostic operations using SMART-TEACH push button and LED indicators

- Code rebuilding algorithm combines multiple scans to reconstruct damaged code information

- GeniusPlus software and proprietary intra-sensor communication protocol eliminate the need for external multiplexer in multi-sensor setup

- Rugged IP65 housing