Sheet Metal Thickness Measurement

Application: Measuring thickness on a metal sheet

Challenges: Precise and consistent sensing while material moves down a conveyor

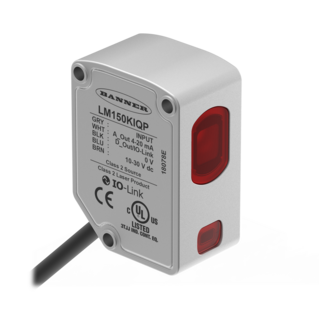

Solution: LM Series Laser Measurement Sensor

Benefits: Measures thickness at micron levels

In the automotive industry, sheet metal stamping is the process of cutting and shaping metal alloys into automotive frame brackets and other forms using a press tool. Metal stamping dies are used to create high precision metal parts that are equal in shape and size.

Automotive metal stamping requires a specific thickness to ensure the parts are equal, and to ensure the die is not damaged during this process. As metal sheets move down the conveyor, laser displacement sensors measure the sheets on a very precise scale to ensure they are the correct thickness. In this sheet metal stamping application, it is important that the frame brackets and other metal components are identical and that the die is not damaged to prevent down time and costly repairs.

Description

The LM Series precision measurement sensor is a perfect solution because it is highly accurate and measures thickness at micron levels. The LM Series can also consistently look at dark targets on these levels. The LM Series is capable of micrometer-level resolutions ranging from 2-4 microns, which gives it the ability to measure thickness of sheet metal quickly and accurately. Thickness measurements are available with Analog, IO-Link or RS-232 Serial Communication.

To eliminate crosstalk between the two sensors, the LM series can be synchronized in a master slave relationship. In this mode, the sensors alternate taking measurements and the response speed triples.