Presence and Orientation of IC Chips Seated in Nests

Integrated circuit (IC) chips must be completely seated and right side up in nests for presentation to a test station. Due to the small size of the targets, a precise measurement solution is required to ensure that each chip is present and oriented correctly in each nest. This article explains how the LM laser measurement sensor solves this challenging application.

In semiconductor manufacturing, integrated circuit chips are tested one at a time for functionality and performance. The IC chips are placed in a nest to be delivered to the test station. For test processes to be completed properly, the chips must be completely seated and right side up in the nests.

There are several common failure modes in this application: no chip in a nest, one chip tilted in the nest (creating a small height difference), two chips stacked in one nest, and a chip upside down in the nest. Multiple sensors are often required to identify these failures. However, test stations do not have space for large vision systems or many sensors. In addition, the nests of chips move quickly, which can be difficult for many sensors to track. A high-speed measurement solution is needed to ensure optimal machine throughput.

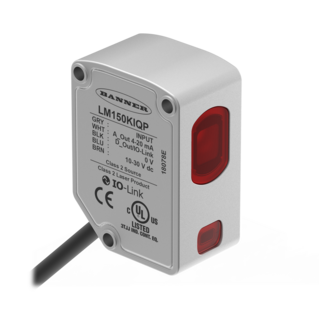

The LM laser distance sensor from Banner Engineering reliably inspects multiple conditions with one compact device and can verify both chip presence and orientation. In addition, with a 4 Khz (0.25 ms) sampling rate, the LM can reliably solve this high-speed application with fast-moving targets.

Inspect Multiple Conditions with One Compact Device

The LM precision sensor can be taught to identify targets at a specific distance. If the sensor reads the correct distance, this means that one chip is present and properly seated in the nest. If the distance reading is smaller than expected, this means a duplicate chip has been placed on top of the first chip. If the distance is greater than expected, this indicates a missing chip.

Thanks to a resolution of 0.002 mm, the LM80 can also measure very small distances that occur when a chip is present but slightly tilted (not fully seated) in the nest. In addition, with a small spot size (0.37 x 0.21 mm at 80 mm), the LM80 is able to take more measurements across the IC chip and provide more reliable measurements to detect the slightest tilt variations.

The LM also features dual teach mode. In this mode, the sensor measures both distance and light intensity. This means that the sensor can identify not only when the target is present within a specified distance, but also when it returns a certain amount of light to the receiver. Because of this, the LM can determine whether an IC chip is right side up, since one side of the chip is a darker color than the other. The intensity of light returning to the sensor’s receiver is lower if the dark side of the chip is facing up.

Typically, an application like this would require multiple sensors: one to measure changes in distance, and one to detect contrast. However, the LM can identify all these conditions (missing, duplicate, incorrectly seated, and upside-down chips) with one reliable, compact device.

Reliable Results with Unmatched Thermal Stability

In addition to measuring multiple conditions with one device, the LM also features exceptional thermal stability for reliable inspections regardless of ambient temperature fluctuations that affect the precision of other sensors. Even a few degrees of temperature change can cause other sensors’ measurement error to double. In comparison, the LM80 has a temperature effect of just +/-0.006 mm/°C. This enables the sensor to remain precise and continue to measure reliably regardless of external temperature changes.

High Precision

The high precision of the LM ensures that parts meet tight tolerances with fewer failures. The LM80 has a 0.002 mm resolution that allows the sensor to identify the subtlest changes in distance. Learn more about laser measurement specifications and how to use them to choose a sensor.

Quick Response Time

A fast 0.5 ms response time and 0.25 ms sampling rate mean the LM sensor provides accurate measurement on quickly rotating parts.

Real World Stability

LM sensors feature a thermally stable design that resists temperature changes, as well as enhanced mounting stability, for high accuracy in the toughest environments. The LM80 has a minimal temperature effect of +/-0.006 mm/°C. This is imperative for high precision applications since even a few degrees of temperature change can cause other sensors' measurement error to double.