Amber Illumination Suitable for Photosensitive Materials

Selecting an illumination solution for photolithography processes is challenging because white light contains a percentage of blue wavelengths, which negatively affect photosensitive materials. Continue reading to learn how Banner’s WLS15 dual color strip lights with amber LEDs illuminate clean rooms without affecting undeveloped photoresists.

In semiconductor manufacturing, the photolithography process involves transferring a pattern from a mask to a substrate using a photosensitive polymer, also known as a photoresist. Undeveloped photoresist is sensitive to white light, especially blue wavelengths (400 nm) that are emitted from fluorescent bulbs and certain LEDs. Therefore, white light cannot be used to illuminate clean rooms during photolithography processes.

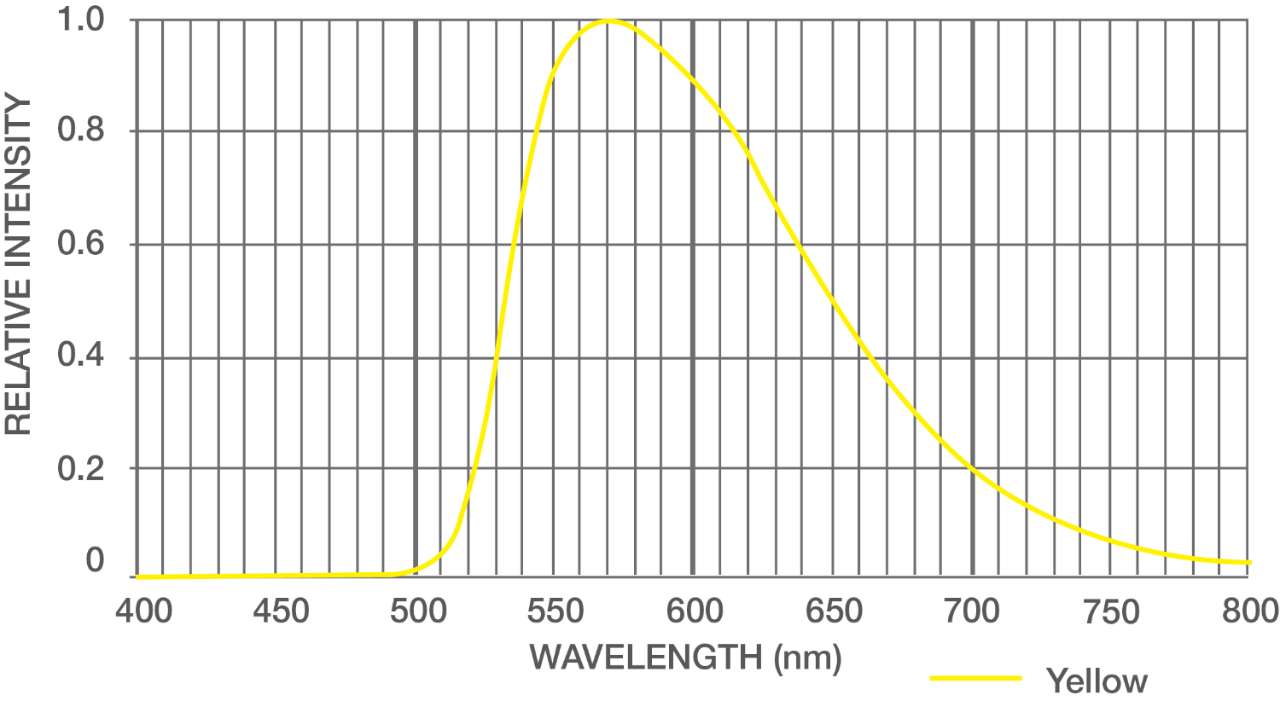

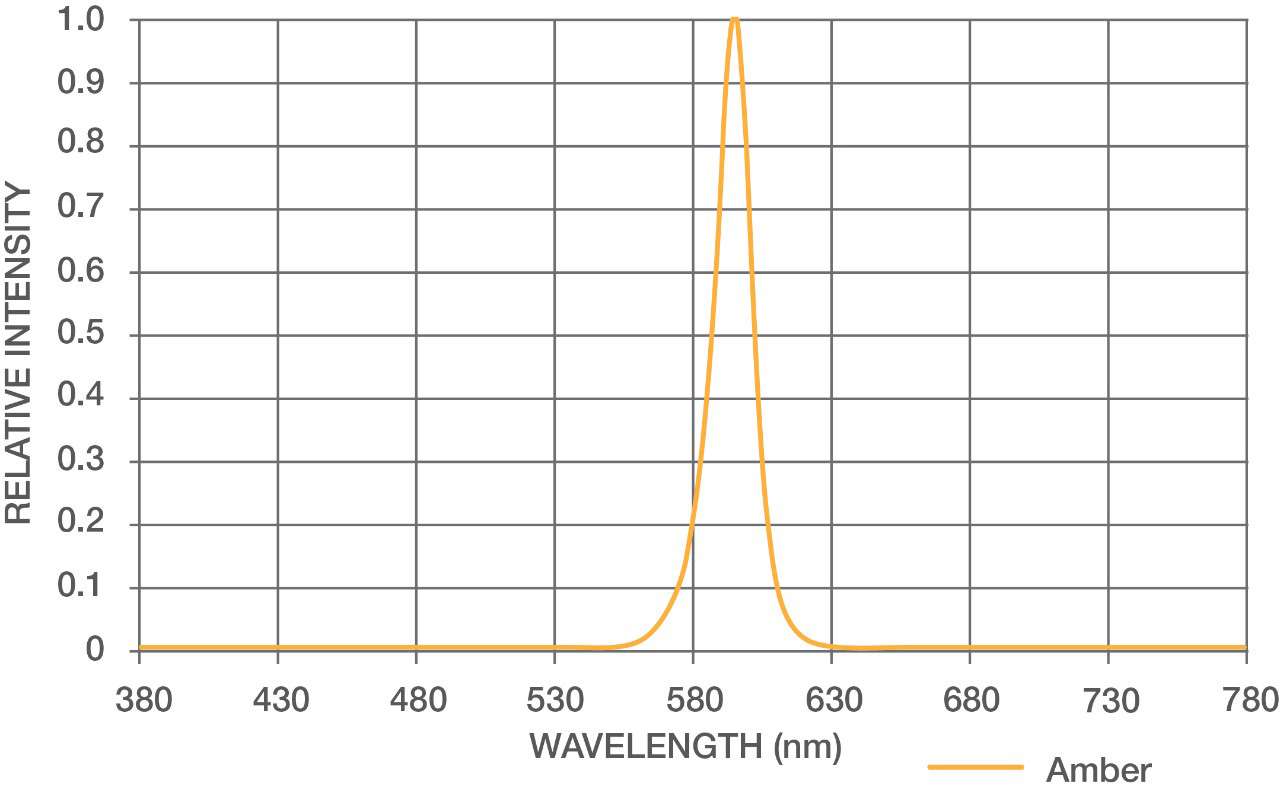

Yellow and amber tinted light can also be problematic if the color is achieved with phosphor-converted LEDs. Phosphor-converted LEDs achieve the yellow color by coating blue LEDs with a phosphor coating and therefore are not suitable for use in photosensitive applications. For example, the WLS15 yellow models use phosphor-converted yellow LEDs (InGaN) and still emit blue wavelengths, as shown in the chart below.

However, the WLS15 amber-colored models are safe for use in photosensitive applications because they are composed of non-phosphor converted LEDs (AlInGaP). These LEDs have a spectral output above 560 nm and a blue wavelength content of less than 0.35%. See the charts below for a comparison of the yellow and amber spectral light outputs.

Dual Color Capability

The dual color capability of the WLS15 strip lights provides additional versatility in photosensitive applications. WLS15 lights with both amber and daylight white LEDs enable semiconductor manufacturers to switch between the colors as needed. When the photolithography process is complete and all photoresist has been developed, the clean room can be illuminated with white light for greater visibility during maintenance and cleaning.

A slim, low-profile housing with versatile mounting options means that the WLS15 can easily be installed into existing cabinets or workstations without obstructing sightlines or impacting existing framework. When compared to standard lights mounted in the ceiling grid, this installation flexibility puts bright light where it is needed most and eliminates shadows. Furthermore, the WLS15 dual-color LED strip light is a self-contained unit, so filters or bulb covers are not required.

Dual-Color Illumination

Dual color capability adds more versatility to the WLS15 Series product line. Select from six different colors to create a dual-color LED strip light for greater visibility and versatility in small-space workstation applications.

Easy and Flexible Installation

The slim 15 mm low-profile design allows for quick installation in areas with limited space. The small strip light does not obstruct sightlines or impact any existing application framework. Flexible mounting options and a wide range of brackets keeps setup quick and simple.