Stocking and Replenishment

Keep Shelves and Stations Stocked and Organized

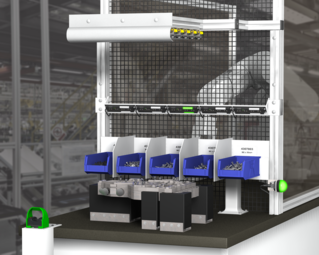

Picking activities are only effective if the correct parts or inventory are put in the right place and ready to be picked. Because of this, an efficient stocking and replenishment solution is a necessity in many industries.

Warehouses and distribution facilities require an efficient method for putting inventory on the shelves so that orders will be easily accessible during fulfillment. In manufacturing facilities, assembly and kitting stations must be replenished with parts before they run out.

Put-to-light solutions improve the efficiency and accuracy of stocking and replenishment activities and can help prevent downtime by reducing delays due to misplaced or incorrect parts.

Stocking and replenishment are critical because misplaced items, incorrect parts, and delays in restocking shelves or workstations can significantly impact productivity downstream.

Proper stocking and replenishment is also essential for error-proofing and quality control. For example, if assembly stations are stocked with incorrect parts, the quality of the assembly may be compromised, and assemblers may not be able to meet production goals. In material handling, misplaced inventory can lead to order delays or mix-ups.

Light-guided putting solutions reduce the risk of errors and help ensure that work areas are properly stocked at all times.

Stocked Workstations Mean No Waiting for Items

- Put-to-light solutions speed up stocking and replenishment times by clearly and visually guiding workers to the correct location for each item.

- Faster replenishment means assemblers and production staff spend less time waiting for more parts and can maintain an appropriate pace to meet production goals.

- Efficient stocking also enables faster and more accurate order fulfillment at warehouses and distribution facilities.

Get the Right Items in the Right Location

- By facilitating proper stocking and replenishment, put-to-light solutions help ensure the quality of the final product.

- In manufacturing facilities, keeping assembly stations stocked with the correct parts reduces the risk of errors down the line.

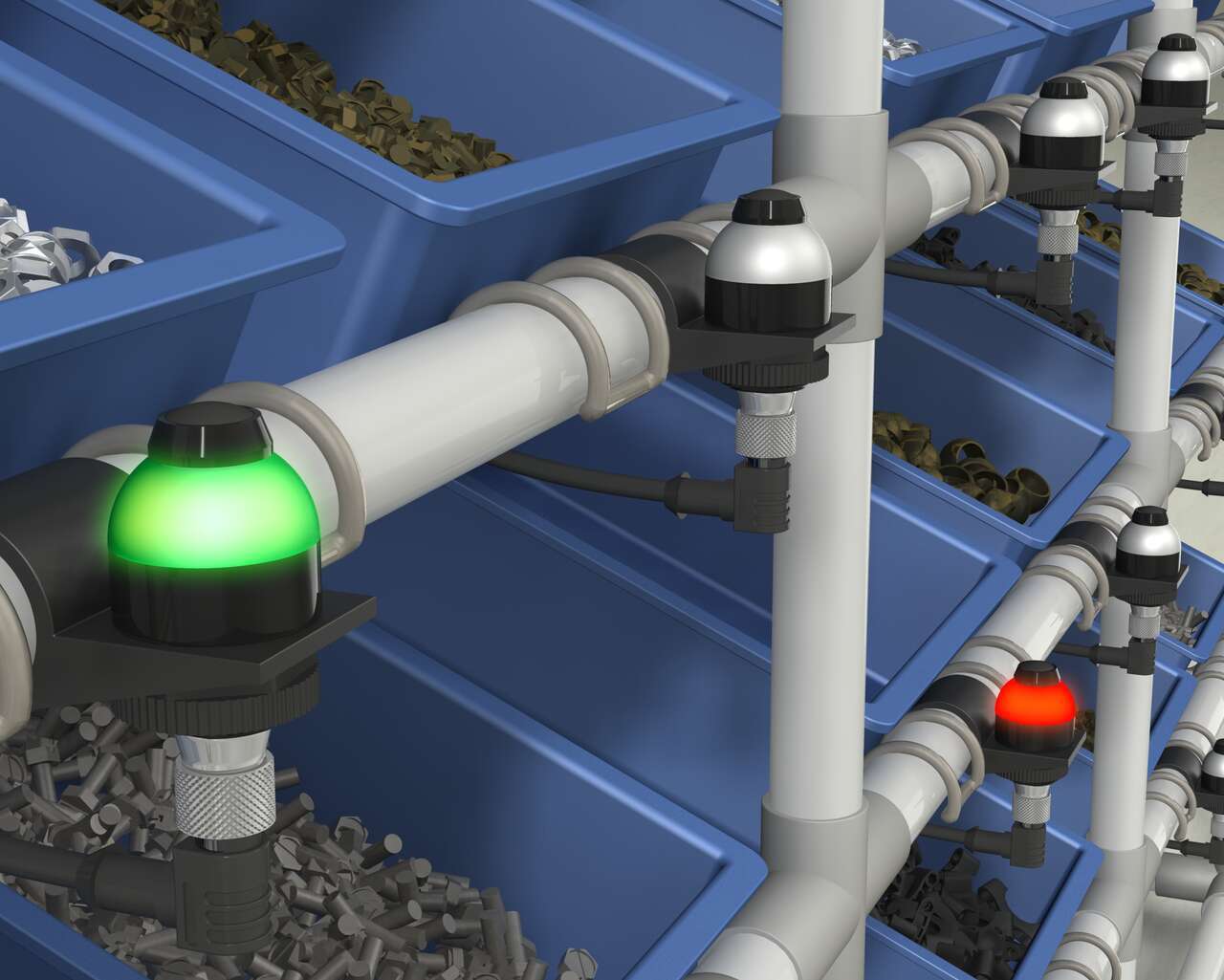

- For example, a put-to-light solution uses light to guide a worker to place the proper size screws in the correct bins so the assembler will pick the right size screw to fasten other parts together securely.

Reduce Recalls & Ensure Customer Satisfaction

- Because put-to-light solutions improve efficiency and reduce errors, they ultimately help save costs and maximize profits.

- Fewer errors mean a lower risk of a product recall due to manufacturing defects.

- Speed and accuracy increase customer satisfaction and confidence, leading to repeat business and higher profits.

Versatile, Scalable Pick-to-Light Devices

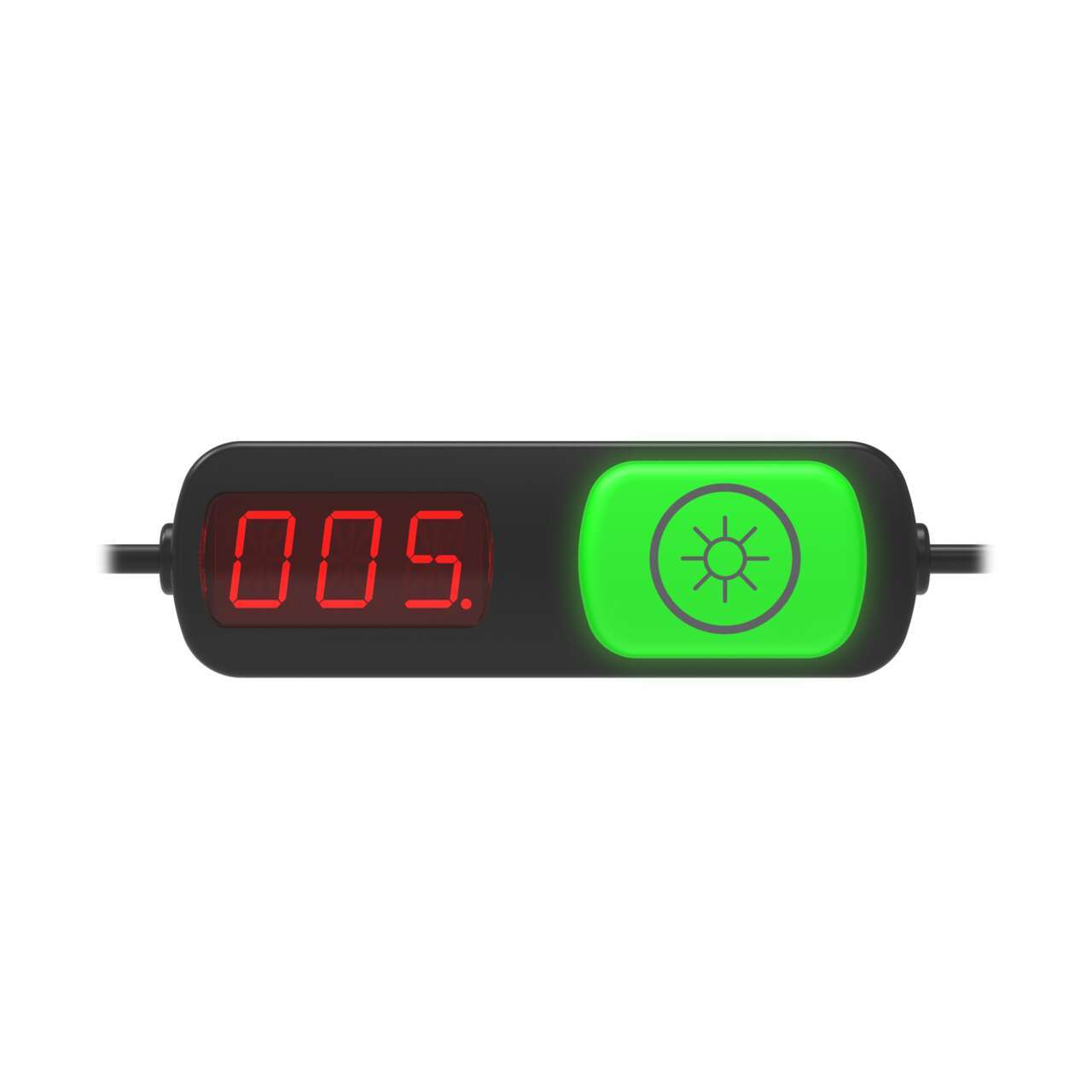

PTL110 pick-to-light devices are multifunctional indicators with options for touch button, optical sensor, and three-digit display, connected in series to create a powerful picking system. With fast response times and flexible installation options, PTL110 systems improve speed, productivity, and quality in picking, kitting and related applications.

- Models available with optical and touch sensor capabilities.

- Optional 3-digit alphanumeric display can be used to indicate part count or provide other instructions.

- M12 connectors for quick and secure installation of multiple devices with no additional cables required.

- Indicator provides fourteen colors and multiple animation functions to differentiate multiple conditions.

- Powered by PICK-IQ®, a purpose-built, Modbus compatible serial bus protocol that uses a Common ID to reduce the typical latency that results from polling multiple devices.

- Can be paired with the DXM700 wireless controller for deployment on carts and mobile picking stations.

Pick to Light Devices

Pick to Light Devices

The S22 Touch Series is a versatile family that combines a bright indicator with solid-state switching capability activated by a simple touch. Ideal for lean manufacturing and bin-picking operations.

- Bright LED indicators combined with touch-activated switching capabilities

- Programmable using Banner's Pro Editor Software and Pro Converter Cable for customization of colors and animation

- Rugged, cost-effective, and easy-to-install multicolor indicator with touch button

- Solid state electronics for long lifetime and reduced maintenance

- IP69 construction for washdown environments

- 22 mm threaded polycarbonate base

- Ergonomic design to eliminate hand, wrist, and arm stress

- Can be actuated with bare hands or gloves