Stretch Wrapping Solutions for Food Packaging

The final step is the stretch wrapper. After cases are stacked on pallets, each pallet needs to be wrapped with stretch wrap material to help protect the finished goods during transport. Containing them with wrapping material helps keep them in place during storage and shipping and minimizes damage to product.

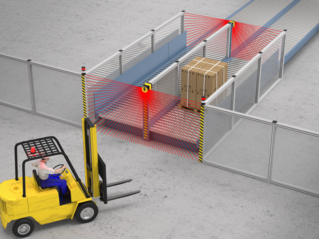

If space allows, the stretch wrapper can be guarded by the same light screens used to guard the palletizer. If not, additional safety products will need to be used as stretch wrapping can cause personnel injury. Robotic arms are typically used to quickly run stretch wrap material around each pallet, and the arm can cause damage if not properly guarded.

Laser distance sensors also work well in this area to determine the position of the top of the pallet since it can change with different case sizes. Monitoring roll diameter is also important at this stage to ensure that wrap material does not run out and slow down packaging. Sensors can be used to determine when rolls are almost empty, and indicator lights alert operators of the issue.

Featured Applications

Pallet Transfer Safeguarding

Due to the dangers associated with a full pallet transfer, horizontal area guarding is needed in order to maximize productivity of packaging while protecting operators from the hazardous motion of a machine.