Vibration Monitoring of Boiler Room Air Handling Unit Prevents Costly Downtime

Predictive Maintenance using Wireless Vibration Sensors

Learn how the installation of Banner wireless vibration sensors and data from the DXM wireless gateway prevented unplanned downtime in this application.

The main air handling unit in the boiler room of a local corporate building was exhibiting potential issues. The employees could not immediately identify the source of the problem and needed to spend costly time and resources on hiring a maintenance technician to solve the issue. The manager of the building wanted to find a long-term solution so that they could identify maintenance issues with accuracy and in a timely manner.

To solve the company’s need for predictive maintenance, they turned to Banner’s wireless vibration monitoring solution. The need called for the company to mount three wireless vibration sensors on the system for further monitoring in the boiler room. Banner’s vibration machine learning algorithm was used on the DXM wireless gateway to baseline and automatically set alert thresholds for each of the three sensors.

After three months of consistent vibration levels, workers observed a clear rise in vibration levels on one of the pillow block bearings that was being monitored. A maintenance technician was called in to replace the bearing before catastrophic failure occurred. Upon replacement and inspection of the disassembled bearing, the technician saw spalling on the inner race of the bearing, as shown in the first photo.

The data was sent from the DXM wireless gateway to the Banner Cloud Data Services (CDS) website, where it could be visualized from any web browser and gave custom email alerts for hands-off monitoring. The first set of graphs above from the bannercds.com website showed that the rise in vibration over the three-month period and the second set of graphs below show the immediate reduction in vibration from the newly installed bearing. After the new bearing was installed, a new vibration baseline and alerts were generated by the machine learning algorithm for ongoing monitoring of the air handling system.

By identifying the mechanical failure early, the scheduled replacement prevented an emergency visit that would have cost two to three times the normal price of maintenance. Without it, there may have been additional damage to the air handling system, causing required workers to stay out of the office until a solution was found, and resulting in added costs and reduced worker production.

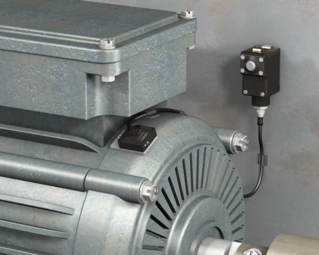

Vibration Monitoring Kit

A cost-effective, end-to-end solution to rapidly integrate IIoT into the most common applications, making it easy to monitor the status of motors, fans, pumps, and similar equipment.

- Includes a wireless DXM gateway controller, wireless vibration and temperature sensor, Cloud Data Solutions platform, and Cellular Data Plan

- Available with either a DXM700 or an IP67-rated DXM1200 for use in challenging environments

- Prepaid Cloud Data Services platform provides graphs, alerts, and long-term data for analysis

- Prepaid Cellular Data Service Plan for widely available network connectivity

- Battery-powered sensors contain both the sensor and wireless node in one compact housing for an easy, “peel-and-stick” installation

- Connect as many as 10 sensor nodes to scale and adapt the solution for specific needs

- Local ISM radio band of 900 MHz frequency for up to 50 times more range than Bluetooth

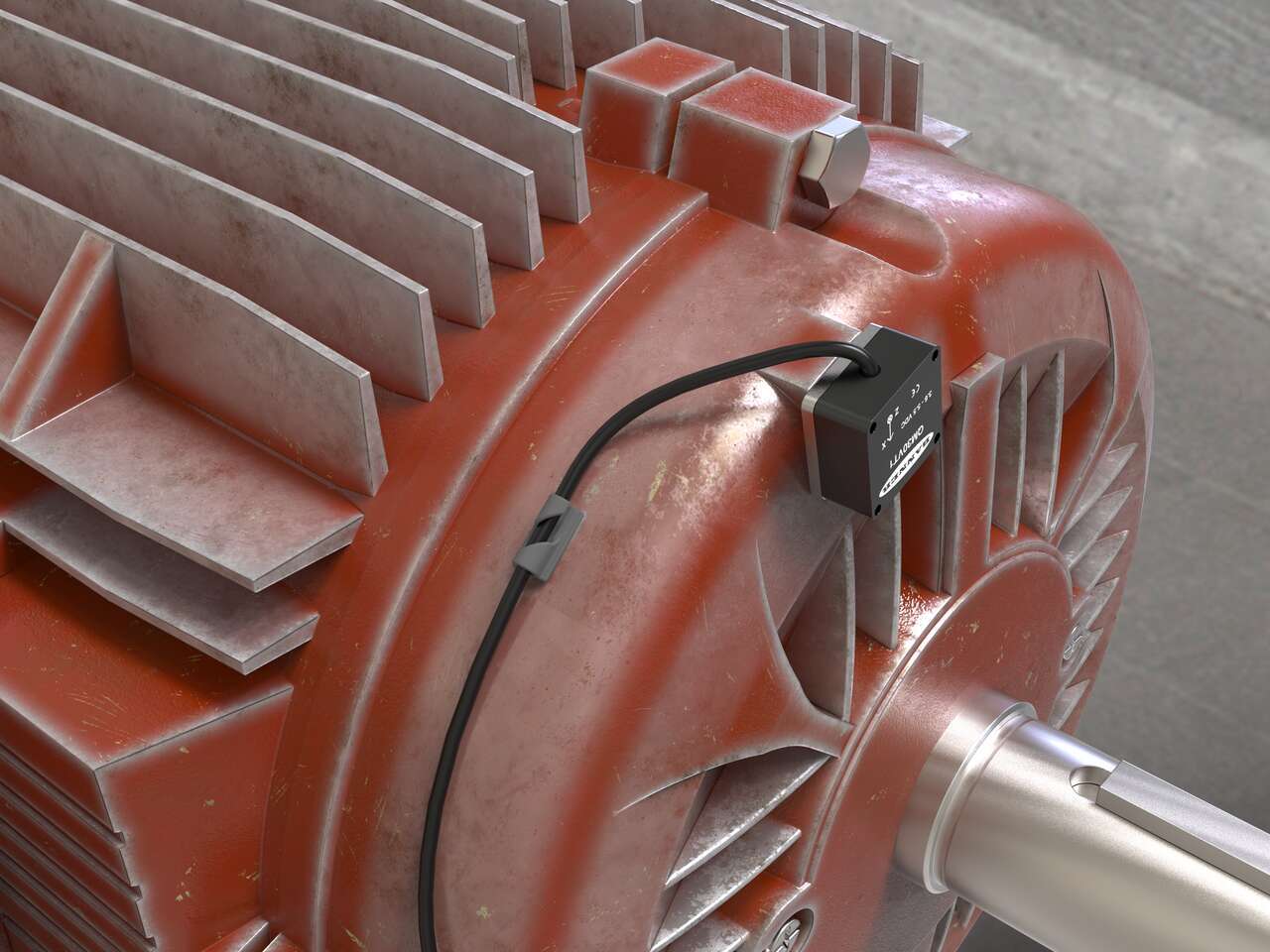

Vibration Sensor

QM30VT Series sensors have a low-profile design and rigid metal construction that reduces resonant interference and increases surface contact, enabling exceptional levels of accuracy in measuring RMS velocity and temperature. They are able to detect even slight increases in machine vibration and temperature for early identification of potential problems.

- Communicates performance data using a MultiHop Modbus Radio or 1-Wire Serial Node to a DXM Series wireless controller or gateway

- Detects potential problems on motors, fans, pumps, and any machine with rotating motion or vibration

- Ultracompact design fits easily in small spaces

- Available in models with a 316L stainless steel housing or a heavy-duty aluminum housing

- Fully compatible with Cloud Data Services software and the Wireless Solutions Kit for Vibration and Temperature

Industrial Wireless Controller

DXM Series industrial wireless controllers are designed to facilitate Ethernet connectivity and Industrial Internet of Things (IIoT) applications. Available with an internal DX80 Gateway or a MultiHop Data Radio, these powerful Modbus communications devices connect local wireless networks with the internet and/or host systems.

- ISM radios available in 900 MHz and 2.4 GHz for local wireless network

- Converts Modbus RTU to Modbus TCP/IP or Ethernet I/P

- Logic controller can be programmed using action rules and text language methods

- Micro SD card for data logging

- Email and text alerts

- Local I/O options: isolated discrete inputs, universal inputs, SPDT (Form C) relay outputs, NMOS outputs, and analog outputs

- Powered by 12 to 30 V dc, 12 V dc solar panel, or battery backup

- RS-232, RS-485, and Ethernet communications ports; and a USB configuration port

- LCD display for I/O information and user programmable LED’s

- Cell modems available for cellular connectivity (sold separately)