Manual Load Weld Cell

Application: Safeguarding manual load welding station

Challenges: Harsh environment

Solution: EZ-SCREEN Safety Light Curtain

Benefits: Rugged housing

A variety of semi-automated operations which involve the manual feeding and/or removal of parts exist within the automotive manufacturing process. In many cases such as this robotic weld cell, operators must be protected from hazards that are created by the automation such as pinch points from clamps and feed table movement.

The solution requires a safeguarding method which can detect the presence of a hand reaching into the station as well as protect from a cycle start if personnel are inside the cell.

Description

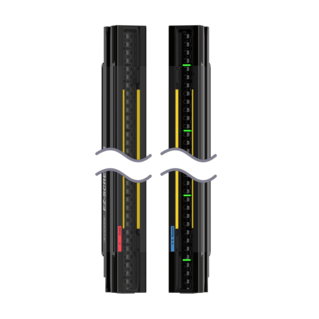

Banner Engineering’s EZ-SCREEN® series safety light curtain system is a well established solution for the harsh requirements of welding equipment. With the ability to cascade (series connect) multiple segments together, configurations such as this horizontal/ vertical pair are easily implemented with standard hardware (no master/slave models).

Additionally, the EZ-SCREEN safety light screen has outstanding on-board alignment and diagnostic aids, does not require an external device for programming and can be enhanced with the addition of Banner’s EZ-LIGHT lighted curtain for remote status indication.