Small Assembly Station Protection with Light Curtains

Application: Safeguarding small assembly workstation

Challenges: Tiny space that cannot have gaps in sensing or physical obstructions

Solution: Banner Engineering's EZ-SCREEN LS Safety Light Curtains

Benefits: End-to-end sensing and flush mounting

Many industries have a variety of smaller assembly stations that need to be safeguarded without sacrificing throughput. Traditional safety light curtains, installed vertically, may require the use of corner mirrors to cover all three sides of a machine which creates physical obstructions to normal material flow and operator motion. Cascaded horizontal light curtains are challenging to mount to ensure no gaps are present in the sensing field corners where the segments joined together. A safeguarding system is needed that seamlessly eliminates blind zones and is also robust enough to resist damage from harsh materials and accidental collisions.

Description

EZ-SCREEN LS safety light curtains have no DIP switches, feature end-to-end sensing, and can be easily installed with automatic configuration. The use of side mount brackets creates a quick and simple installation with adjustments made from the front side of the EZ-SCREEN LS arrays, saving time during setup.

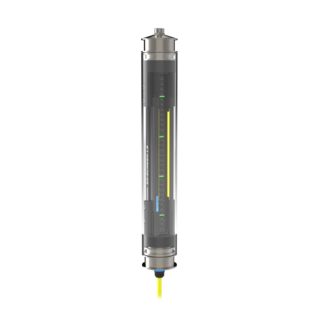

Maximizing machine uptime and reducing repair and replacement expenses helps companies remain competitive. It is important to find a solution that is very resilient to damage and requires less maintenance to maintain high quality performance. Fortunately, Banner’s EZ-SCREEN LS is incredibly robust. It has a thick aluminum housing, metal end caps and also has a recessed window to avoid damage from impact. The connection cable exits the housing at a right angle for flush mounting which greatly reduces the probability of connector damage due to dropping or physical impact.

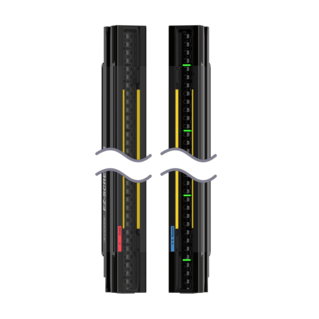

The EZ-SCREEN LS also has highly visible bi-color alignment indicators built into the entire length of the receiver window aiding in initial setup and future maintenance. When an area of the sensor is not aligned properly or the window needs cleaning, the green lights will turn red in the affected area making troubleshooting intuitive and expediting corrective measures. Optional remote indicators are also available for the EZ-SCREEN LS allowing light curtain status to be viewed from a distance to further support productivity in a lean manufacturing environment.