Benefits of Polarized Coaxial Optics for Detecting Clear Objects

Image: Coaxial Optics Design

Summary: Photoelectric sensors used to detect clear, translucent, and transparent objects must be sensitive to slight variations in light, which can make them susceptible to false detection from errant and reflected light. Sensors utilizing a polarizing filter and coaxial optical design restrict the amount of light that enters a sensor’s receiver. Read on to learn why this is important and to learn about additional benefits offered by polarized coaxial optics.

Retroreflective Sensors for Clear Object Detection

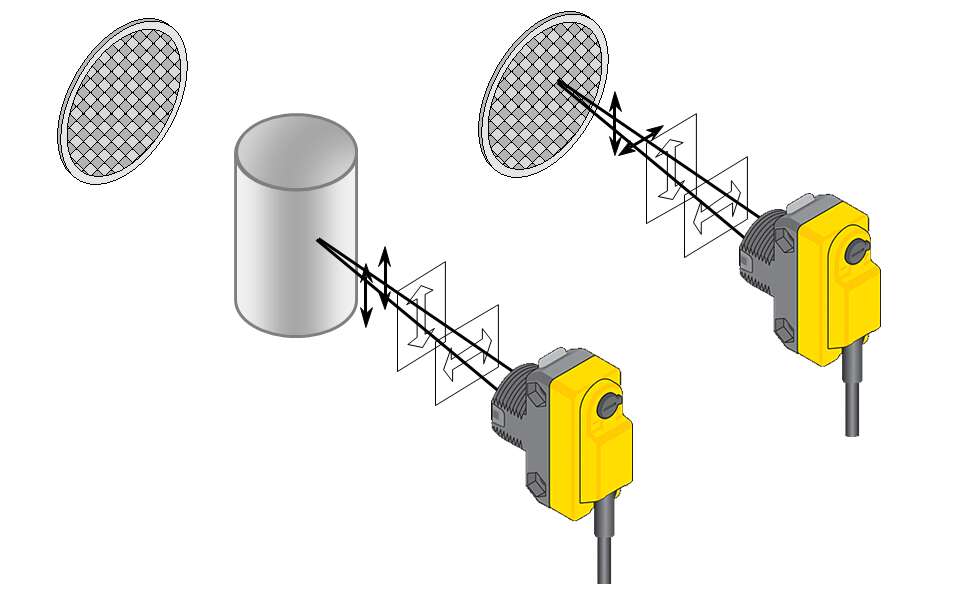

Retroreflective photoelectric sensors are used to solve a great number of applications. In this popular sensing mode, both the emitter and receiver are in the same housing. The emitter will direct an LED generated sensing beam to a reflector, which redirects the beam back to the receiver. An object passing between the sensor and reflector will disrupt the sensing beam and be detected.

Because the emitter and receiver are housed together, only one side of an installation needs to be powered, simplifying wiring and installation and reducing overall cost. Additionally, this sensing mode offers a relatively high amount of excess gain which increases the sensing range as well as the sensor’s ability to overcome environmental contaminants like dust or residue buildup on the sensor or reflector.

Being Sensitive to Slight Variations in Light

Retroreflective photoelectric sensors used in clear object detection applications offer the same powering, installation and space advantages identified in the preceding paragraph. Additionally, these sensors perform reliably over longer distances, offer greater levels of precision, and have quicker response times when compared to many other sensing technologies used in these applications. However, the high levels of excess gain typically associated with this sensing mode will cause the sensing beam to see through many clear objects and miss detection.

Retroreflective photoelectric sensors used in these applications utilize an internal algorithm that makes them more sensitive to low levels of contrast. A transparent object entering the sensing beam will attenuate a small, but perceivable percentage of the emitted light and will be detected. These sensors also have much lower levels of excess gain, which prevents them from seeing through clear objects. However, this makes them more sensitive to environmental contaminants, which can negatively affect performance and longevity. An internal compensation algorithm that automatically adjusts to contamination on the sensor or reflector, as well as adjusting to changes in ambient temperature is often used to mitigate these effects.

Overcoming the Challenges of Reflected Light

Many clear targets (shiny glass or plastic, faceted containers, glossy films, etc.) can have reflective properties. Similarly, equipment and background objects may also reflect light. Light reflecting from these objects back to the receiver of a sensor can trigger false detections.

Polarization Filters

Like polarized sunglasses, a polarizing filter used with a photoelectric sensor will only allow light at a certain plane to enter the receiver. This helps the sensor differentiate between a shiny or transparent object and a reflector. The emitter directs a beam of linearly polarized light to the reflector which rotates the plane of polarization of the light by 90 degrees. This change in polarization allows the light from the reflector to reach the receiver. When the sensing beam hits a shiny object, the object will return light on the same plane as it was emitted, effectively blocking the light from the receiver and signaling a broken beam.

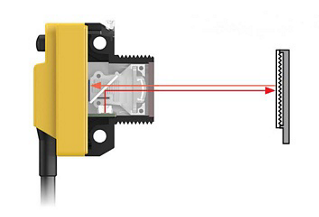

Coaxial Optics

Retroreflective sensors that do not have a coaxial optical design triangulate light from the emitter to the reflector and back to the receiver, which is located adjacent to the emitter. This triangulation creates a detection “dead zone” at the face of the sensor where the emitted and reflected light is furthest apart.

Sensors utilizing a coaxial optical design emit and receive the sensing light beam along a single narrow axis. Light is emitted and received through a single lens with a narrow aperture and the sensor measures the small angle deviation in light between the emitted beam and the reflected beam. The sensor will detect objects at any distance from its face out to the reflector, with no dead zone. The distance from the sensor to the reflector can be quite short, ideal for installations with limited space. This design also severely limits the opportunity for errant light to enter the sensor’s receiver. Used in combination with a polarizing filter, these sensors are highly resistant to false detection caused by reflected light.

Coaxial optical design has other advantages too. The particularly narrow beam, small spot size and insensitivity to sensor rotation associated with this design is ideal for precise leading edge detection and for detecting the narrow gaps between objects common to many high speed counting applications. Additionally, the sensing beam will pass through a small hole unaffected, enabling the use of a shield or enclosure to protect the sensor from environmental challenges, such as high-pressure washdown.

Conclusion

Retroreflective photoelectric sensors are a popular choice for solving clear object detection applications. They are cost-effective, easy to power and install, offer fast response times and high levels of precision. The light sensitivity required to reliably detect clear objects makes these sensors susceptible to false detection caused by reflected light. Sensors utilizing a polarized coaxial design are highly resistant to errant and reflected light. Additionally, this design eliminates detection dead zones between the sensor and the reflector, offers very high levels of positional accuracy, and makes it easy to protect a sensor from environmental hazards.

For more information about clear object detection, contact one of our experts or sign up below to receive future updates.

Featured Products

Related Articles

How to Choose the Best Sensor for Clear Object Detection

Understand the differences between common sensor types in Clear Object Detection applications, such as ultrasonic vs. photoelectic retroreflective sensors.

3 Solutions for Semiconductor Wafer Presence Detection

See 3 solutions to reliably detect clear and reflective semiconductor wafers in a vacuum chamber.

Why Use Polarized Coaxial Optics For Detecting Clear Objects

Clear object detection sensors are sensitive to variations in light and benefit from polarized coaxial optical design to reduce false detection from reflected light.