In a World of Jams

By: Seth Carlson

Industry Growth Leader: Material Handling & Logistics

We live in a world where an endless supply of products are served up to us on a wide variety of digital platforms via sophisticated algorithms that know what we “need” before we ever know we “need” it. Within seconds, and with the ease of turning on the kitchen faucet, those items we “need” are on the way to our front stoop. I personally demand it, you demand it, our customers demand it.

Now, in this industry there are all manners of established technology and physical processes that move that “need” effectively from point A to point B with 99% of it taking place well before it reaches the delivery truck. Conveyance systems are the bread and butter of the material handling industry and the lifeblood of getting those parcels out the door in proper fashion.

In a perfect world, the conveyance system works as designed, sending boxes, bubble packs, poly bags, and mailers filled with all manner of products from dog food and power cords to lip gloss and peanut butter. This seemingly random group of items is sent to their designated destinations at what appears to be effortless speed. Parcels bound for a plane’s cargo hold, semitruck trailer, and delivery truck ultimately find their way to their intended customer anywhere around the world. The planning and timing of such a system is often talked about in milliseconds, leaving razor thin margins for error.

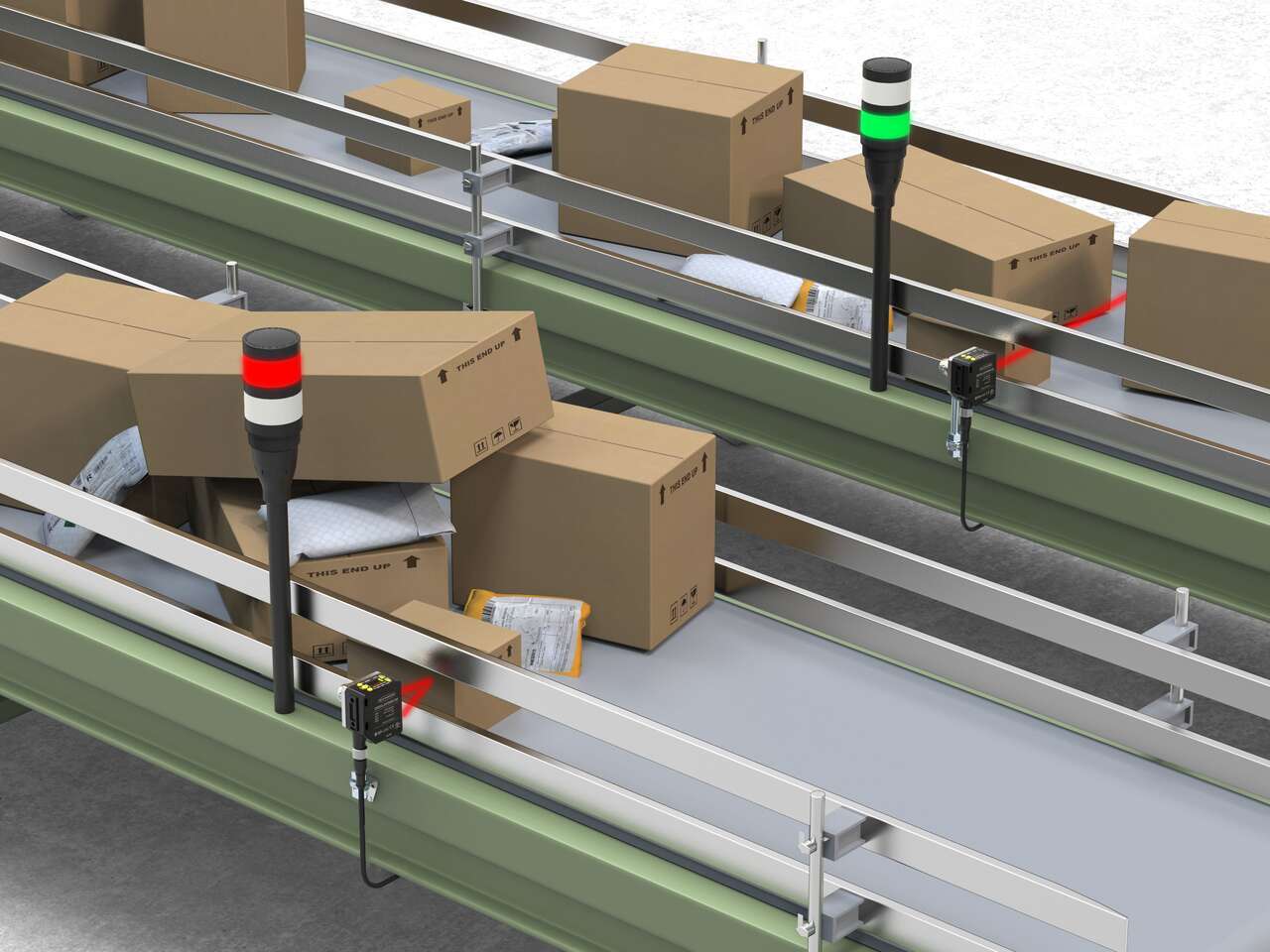

Today’s conveyance systems are designed and operated to ensure product is moved in the most timely and efficient way possible. They are sophisticated and, arguably, technological marvels. Automation technology, including rapid leading-edge detection, vision systems, and localized indication, has allowed these swift conveyance systems to become ubiquitous. Despite all this advancement in automation there remains a very manual problem: jams!

Jams happen constantly, consistently, and without fail. Everything can be going along smoothly at breakneck speed with little cause for concern until a small poly bag containing the hottest new piece of athleisure wear catches on the rail around a curved section of conveyor. That seemingly inconsequential action starts a chain of events that brings the conveyance to a standstill, thereby delaying the plane, semitruck, and delivery truck, all before the recipient’s cell phone pings with a notification stating, “Your package has been delayed.” I hate that message. You hate that message. The customer hates that message. We ALL hate that message.

Again, these systems are measured and calibrated down to the millisecond, so if there is an easy way to save minutes (never mind the seconds and milliseconds), such a solution would prove invaluable. When you add up the milliseconds, seconds, and minutes, the sum will always lead to one thing: a lack of throughput measured by parcels per hour. Throughput is the ultimate barometer for determining the effectiveness of a conveyance and material handling system. Finding ways to make up those seconds and milliseconds will directly improve that target count and ultimately the bottom line.

Jams are not a new conveyance problem. Historically the solution was to adjust the timing delays on basic photoelectric sensors. Depending on how the timing was set up, the conveyance system would be prone to two different problems. The first was late notification of jams; 30 seconds could pass before a jam would be declared. Thirty seconds may not seem like a long time, but it is when packages are flowing at a rate of nearly 100 feet per second. You can bet that a stack of packages at that rate can cause debilitating damage to parcel and mechanical systems alike in a short period of time. The second problem experienced, and often overlooked, is the sharp increase in false jams due to simply too high of a flow, a direct byproduct of those savvy marketing algorithms working to increase your, my, and the customer’s need to have our stuff now! False jams causing operations personnel to be constantly sent on wild goose chases never go over well. Neither of these two “solutions” actually solve the pain point experienced by so many, despite the sophisticated systems.

Reliable, accurate, and fast detection of jams while avoiding the phantom jam is a problem that Banner Engineering is in a unique position to solve. By replacing legacy technology with an updated Q5X jam detection sensor, conveyor systems and operators can detect a jam quickly and accurately. Guessing whether a declared jam is a real jam is not a problem today’s advanced systems and engineers should have to deal with. Damaged equipment, unnecessary downtime, and decreased productivity are not compromises that need to be made just to meet our personal needs, not to mention the customer’s.

Every day, as countless products are served up, ordered, demanded, and expected to be delivered in record time, many things can cause delays. Jams don’t need to be one of them.

Watch the Q5X Jam Detection Sensor in Action

Related Links

-

Q5X Jam Detection

Whenever items on a conveyor unexpectedly get stuck and cause a jam, it leads to a potentially costly production delay if not resolved quickly. The Banner Q5X Jam Detection Sensor is a plug-and-play solution that immediately alerts operators whenever a physical jam occurs.

-

Q5X Series High Power, Multi-Purpose Photoelectric Sensor

A powerful, problem-solving sensor in a cost-effective device with industry-standard rectangular housing. With a range from 50 mm to 5 m, the Q5X provides reliable detection of the most challenging targets.