面向食品包装的装箱解决方案

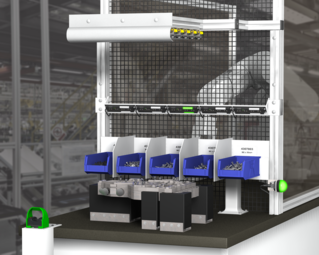

空箱组装后,它们将转移到装箱机站,在这里,食品盒将上架,然后包装在箱子中来进行运输。封好的食品盒进入装箱机区域时,会对它们计数,并准备好转移到箱子中。

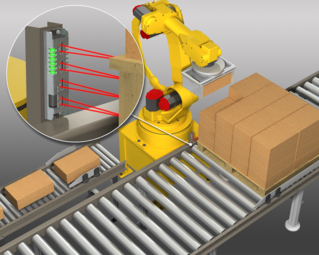

确认每个箱子的位置后,配备真空杯的机器人将一次拾取多个食品盒,并将其逐个转移到箱子中,直到箱满为止。使用自动化机器人可以加快包装过程并提高生产效率。

传感器对食品包装计数,并确认它们正确上架,同时也会确认箱子是否存在。箱子高度也会进行监测,确保每个箱子已满,然后再继续沿生产线行进。 条码监测 对于确保包装的内容物正确无误至关重要。

这方面的检测可能较有挑战性,因为食品盒有许多不同的颜色和尺寸,因而需要使用更高级的传感器解决方案。

特色应用

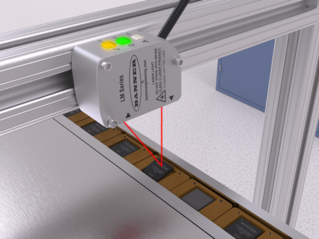

Counting Food Cartons for Correct Packaging

Banner’s WORLD-BEAM QS18LP laser sensor accurately inspects every carton that passes on the conveyor, ensuring the robot is triggered to load cartons into the package. With a visible laser sensing beam, the QS18LP provides precise position control, which is ideal to ensure accurate counting of cartons at a close range. The rugged QS18LP is also ideal for confined spaces and is easily set up along a conveyor for accurate sensing. With highly bright LEDs, operating status is visible from 360⁰.

Detecting Different Size Packages on a Conveyor

Banner’s S18-2 barrel sensor is a cost-effective, reliable sensing method for this type of application. Its small size makes it easy to integrate along the manufacturing line, and its competitive price means it is well-suited for applications requiring multiple sensors. With a powerful and bright visible red emitter beam, the S18 sensors are easy to align during set up.

检验食品纸箱上的日期/批号

邦纳 PresencePLUS P4 密封式 OMNI 视觉传感器坚固耐用,适合用于日期/批号检测,因为这款传感器采用光学字符验证 (OCV) 检测,可确保正确、清晰地印制日期和批号。它的外壳防护等级达到 IP68,是食品和饮料行业应用的不二之选,因为它能耐受恶劣的冲洗环境。P4 OMNI 传感器通过检验包装盒的边缘,可轻松找到需要检测日期/批号的纸盒区域。Wi

.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![指示无人驾驶车辆的状态 [成功案例]](/content/dam/banner-engineering/photography/general---stock-photography/stock_photo_new/AdobeStock_189577689.jpeg/jcr:content/renditions/cq5dam.thumbnail.319.319.png)

![用于满足质量标准的综合检测[成功案例]](/content/dam/banner-engineering/3d-renders/application-notes/wcc-migration/2013/iVu-PLUS-TG-Cap-and-Orientation-Inspect_Detergent.psd/jcr:content/renditions/cq5dam.thumbnail.319.319.png)