远程监控边缘设备

何为远程监控?

通过远程监控可收集和分析来自传感器及其他现场设备的数据,帮助工厂洞察机器、流程和人员的绩效。另外还可以从任意位置实时访问传感器数据,也可以记录数据以便进行长期分析。

继续阅读本文,了解远程监控技术如何彻底改变工业自动化,为智慧型工厂提供更出色的运营洞察,并实现更卓越的数据驱动型决策。

设备综合效率 (OEE)

追踪和减少浪费的原由

远程监控为寻求提高整体运营效率的设施带来了诸多优势。 例如:

- 远程监控技术为 OEE 计算提供数据。

- 洞察效率低下的时间和位置,减少浪费,最大限度减轻其影响。

- 用户可以访问来自于机器传感器和指示灯的数据,随时跟踪性能趋势,确定改善措施。

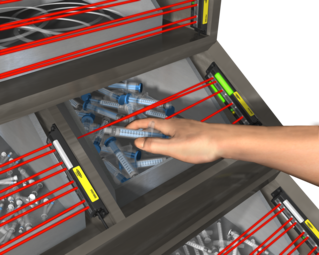

工厂通信与流程优化

简化物料呼叫、拾取等等

远程监控技术还能提高手动装配和生产线的效率。 工厂无线通知系统的一些优势包括:

- 管理人员可减少不必要地检查线路所花费的时间,远程监控多条线路,并提高工作效率。这样一来,管理人员就能在出现问题时快速应对,将注意力集中在最需要的地方。

- 在管理物料呼叫、服务或拾取并作出回应时,可以提高效率。

- 减少工人在需要之时离开工位向管理人员寻求帮助的需要。

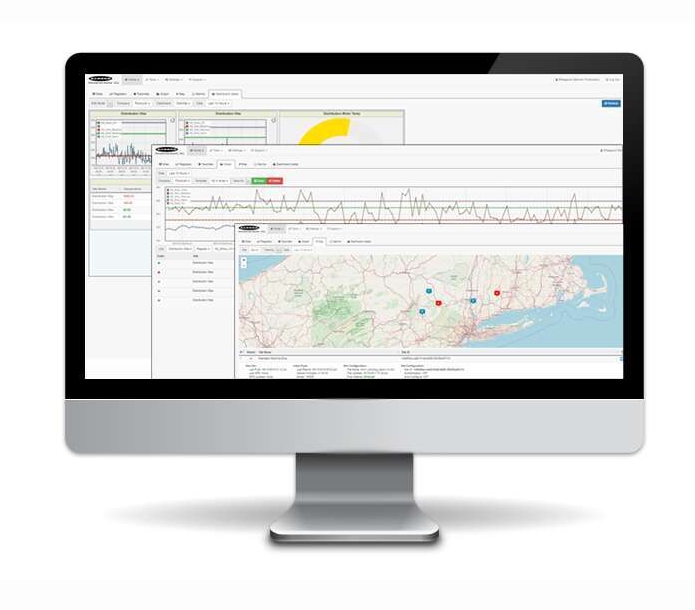

Cloud Data Services

面向工业物联网应用的软件

互联数据解决方案软件是基于Web的平台,允许用户访问,存储,保护和导出由邦纳的有线和无线传感器收集的关键数据。该软件可补充您的无线产品组合,并为客户提供完整的端到端 IIoT解决方案,以解决工业市场最紧迫的问题。

- 借助分析和可视化工具,该软件可提供可操作的分析,使您能够在工厂车间解决真正的挑战。

- 存储数据并分析一段时间内的趋势

- 使用互联网连接设备随时随地远程访问数据。

- 通过电子邮件或短信获取实时通知。

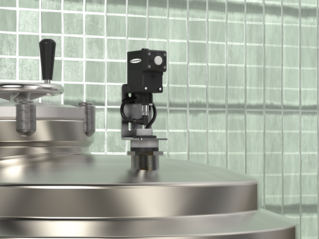

QM30VT 系列

振动和温度传感器

QM30VT系列传感器采用紧凑设计和坚固的金属结构,可减少共振干扰并增加表面接触,从而在测量RMS速度和温度时提供卓越的精度。它们 甚至能够检测到机器振动和温度的轻微升高,以便及早发现潜在问题。

- 使用多跳Modbus无线电台或有线节点将性能数据传递到DXM系列无线控制器或网关

- 检测电动机,风扇,泵和任何旋转运动或振动的机器上的潜在问题

- 超紧凑设计可轻松安装在狭小空间

- 提供带有316L不锈钢外壳或重载铝外壳的型号

- 与CDS解决方案软件和 振动温度无线解决方案套件完全兼容