备货补货

保持货架和站台的库存和组织性

只有当正确的零件或库存被放在正确的位置并准备好被拣选时,拣选活动才会有效。正因为如此,高效的备货和补货解决方案对许多行业不可或缺。

仓库和配送设施需要一种有效的方法,将库存放在货架上,以便在执行过程中容易获得订单。 在生产设施中,组装和配料工位必须在零部件用完之前及时补充。

亮灯拣选解决方案提高了备货和补货活动的效率和准确性,并且可以通过减少由于错放或不正确的零件造成的延误来帮助防止停机。

降低出错风险,提高质量

将正确的物品放在正确的位置

- 亮灯拣选解决方案可以更好地做到备货补货,有助于确保最终产品的质量。

- 在生产设施中,为装配工位备储备正确的零件,可降低生产线出错的风险。

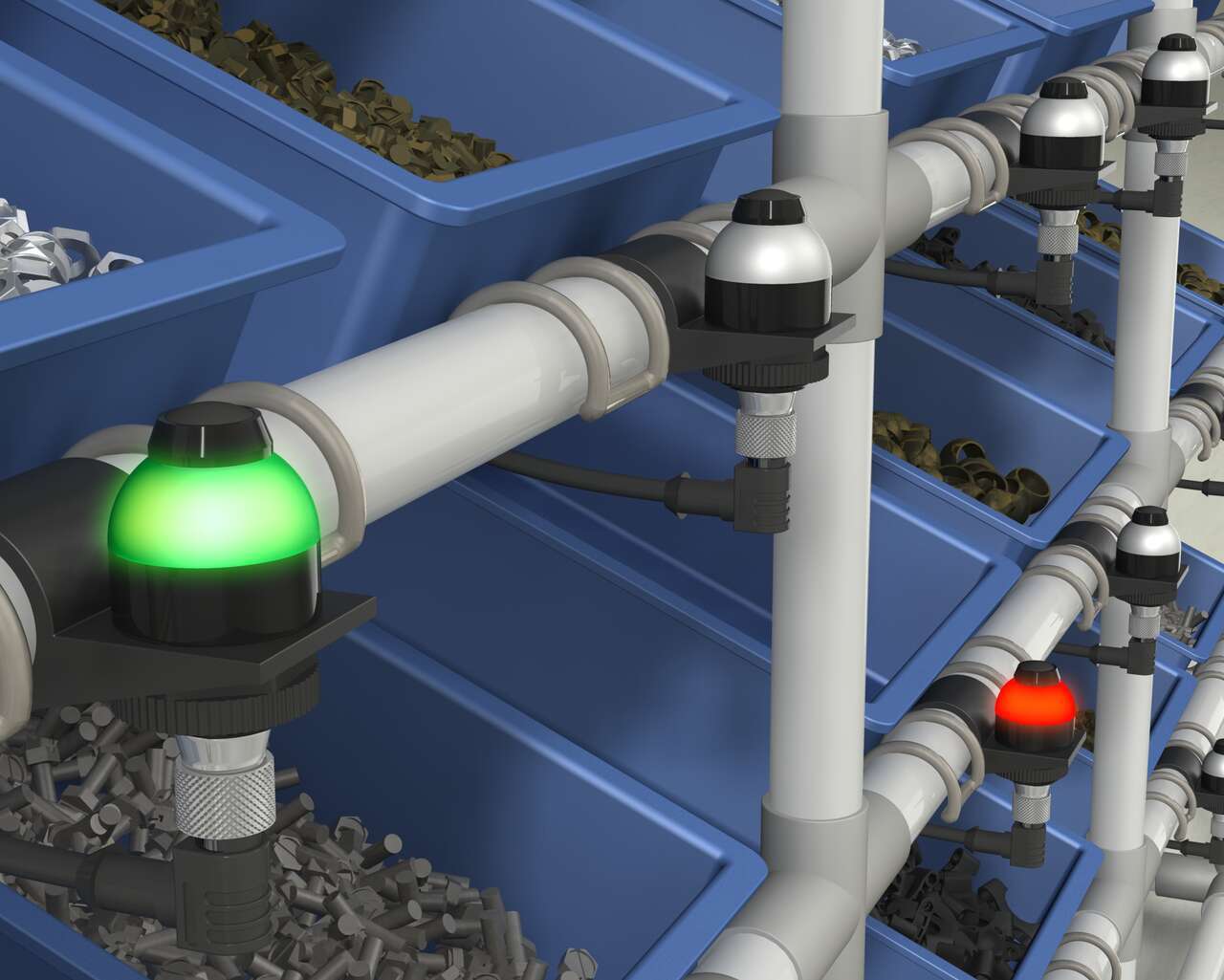

- 例如,亮灯拣选解决方案利用灯光引导工人将合适尺寸的螺钉放入正确的料箱,这样装配工人就能挑选到合适尺寸的螺钉,将其他部件牢固地固定在一起。

节约成本,实现利润最大化

减少召回,确保客户满意

- 由于亮灯拣选解决方案可提高效率,减少错误,因此最终有助于节约成本并实现利润最大化。

- 错误越少,意味着因制造缺陷而召回产品的风险越低。

- 速度和准确性可提高客户满意度和信心,带来回头客和更高利润。

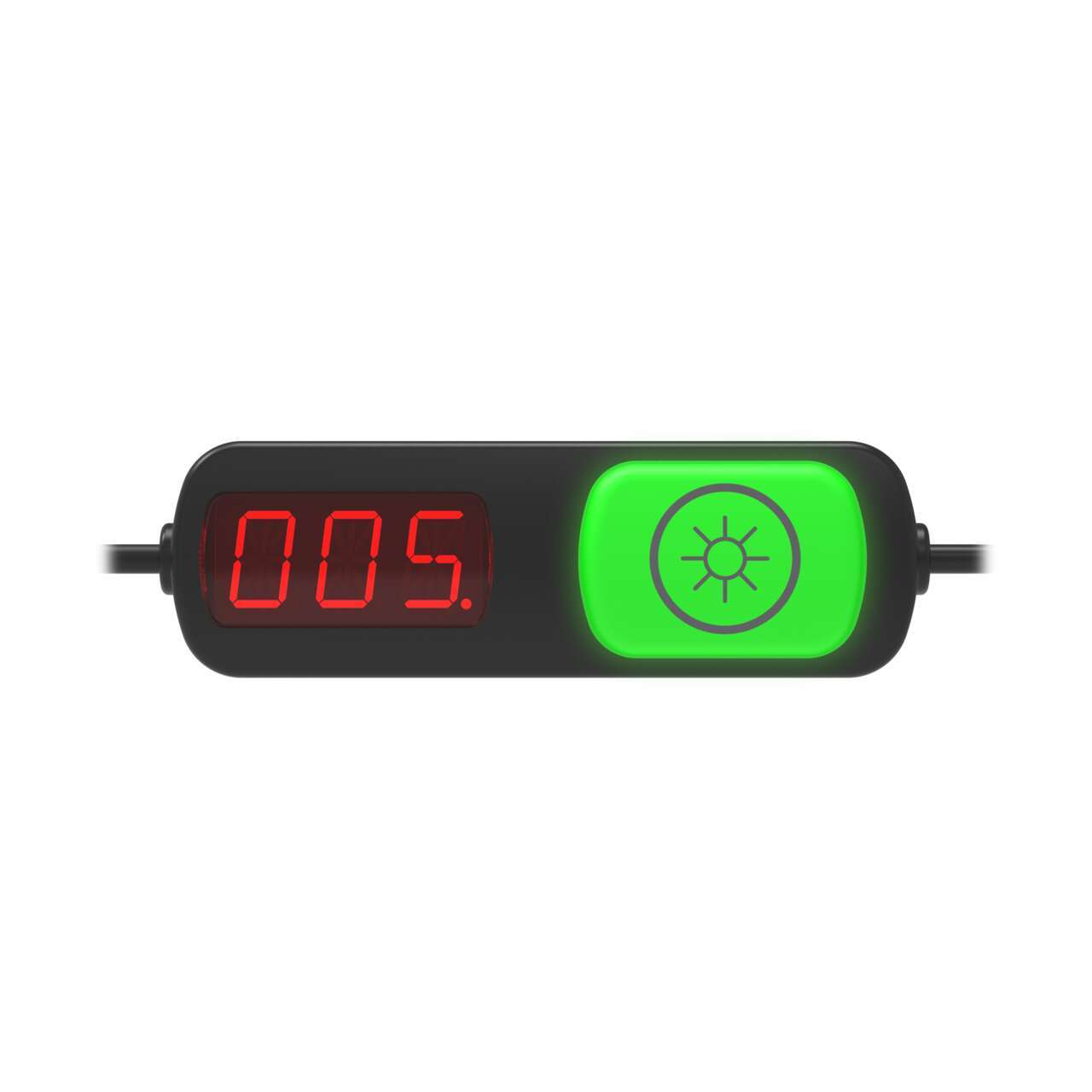

PTL110 系列

多功能的可扩展拾取指示灯装置

PTL110 拾取指示设备是多功能指示灯,可选配触摸按钮、 光学传感器和三位数显,通过串联打造强大的拾取系统。PTL110 系统响应迅速,安装灵活,可提高拾取、套件制作及相关应用的速度、生产率和质量。

- 提供具备光学传感器和触摸传感器功能的型号。

- 选配的 3 位字母/数字显示可用于指示部件计数或提供其他指令。

- M12 连接器支持快速、安全地安装多个设备,无需额外布线。

- 指示器提供十四种颜色和多种动画功能,以此区分多种情况。

- 由 PICK-IQ™ 提供支持,这是一种专用的 Modbus 兼容串行总线协议,它使用通用 ID 来减少轮询多个设备所产生的典型延迟。

- 可与 DXM700 无线控制器配对,以便在推车和移动拾取站中部署。

K50 Pro 系列

拾取指示灯装置

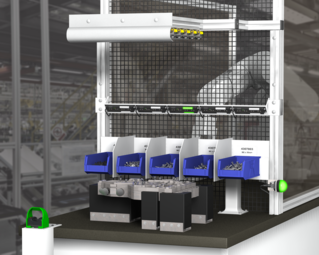

S22 Pro 系列

拾取指示灯装置

S22触摸式系列是一个多功能产品系列,将明亮的指示灯与固态切换功能相结合,只需触摸即可激活。适合精益生产和零部件拾取操作。

- 明亮的 LED 指示灯与经由触摸激活的开关功能融于一体

- 使用邦纳的 Pro Editor 软件和 Pro Converter Cable 进行编程,定制各种颜色和直观显示效果

- 多色指示器带触控按钮,坚固结实、经济高效、安装简便

- 固态电子设备,使用寿命长,维护成本低

- IP69结构,适用于冲洗环境

- 配备 22 mm 螺纹聚碳酸酯底座

- 符合人体工程学设计,可消除手部、手腕和手臂承受的应力

- 在启动按钮时戴或不戴手套皆可