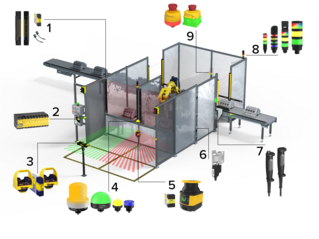

动态指示状态

清晰传达高级状态

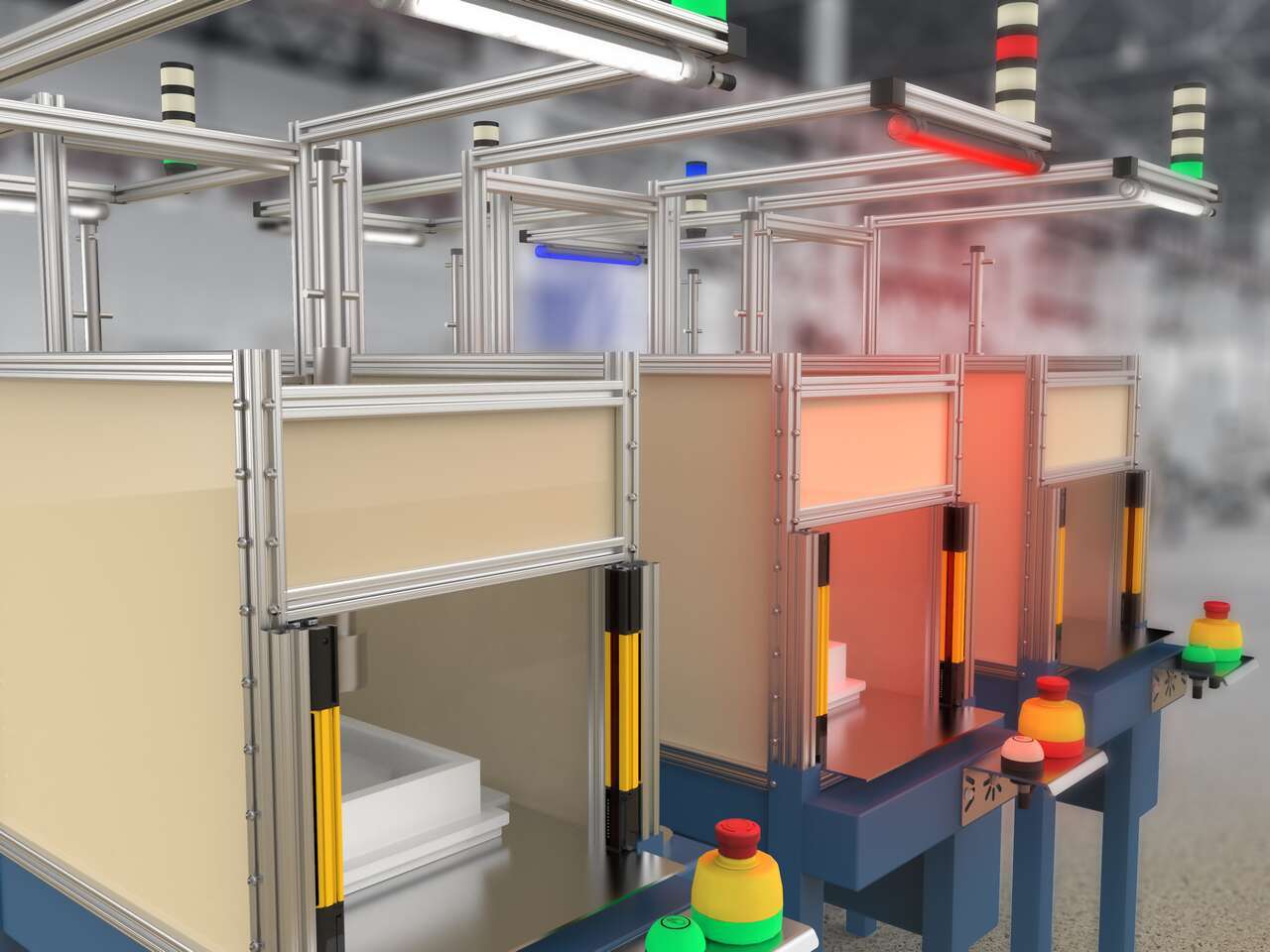

一直以来,指示灯都是机器的可视化语言。然而,传统指示灯的功能有限,通常只能用 3-5 种颜色来表示各种状态。有时,这些颜色不足以体现出现代机器和流程的复杂性。

可编程 RGB 指示灯提供了更多颜色,并且可以根据需要进行更改。许多 RGB 指示灯还具备预定义的直观显示效果和高级功能,能扩展指示范围,指示活跃的机器状态。

为机器的视觉语言增添细节

深入了解

动态状态是指机器或流程的各种状况,这些状况通常难以用传统的常亮或闪烁来传达。 这方面的示例包括机器预热状态、过渡状态、剩余产距时间、料位等等。

进行高级指示需要具备更广泛的颜色选择空间。有了更多种颜色,就能为每个状态或组装步骤提供有别于其他步骤的唯一指示,从而消除混淆,加速信号解读。

额外的颜色和直观显示效果还可以醒目直观地向操作员和主管等人传达高级状态。 它们为您的机器视觉语言增添了细微差别,与传统指示灯相比,能一目了然地传达更丰富的状态信息。

继续阅读,进一步了解有关动态机器状态的指示解决方案,或联系我们,来讨论您的具体应用。

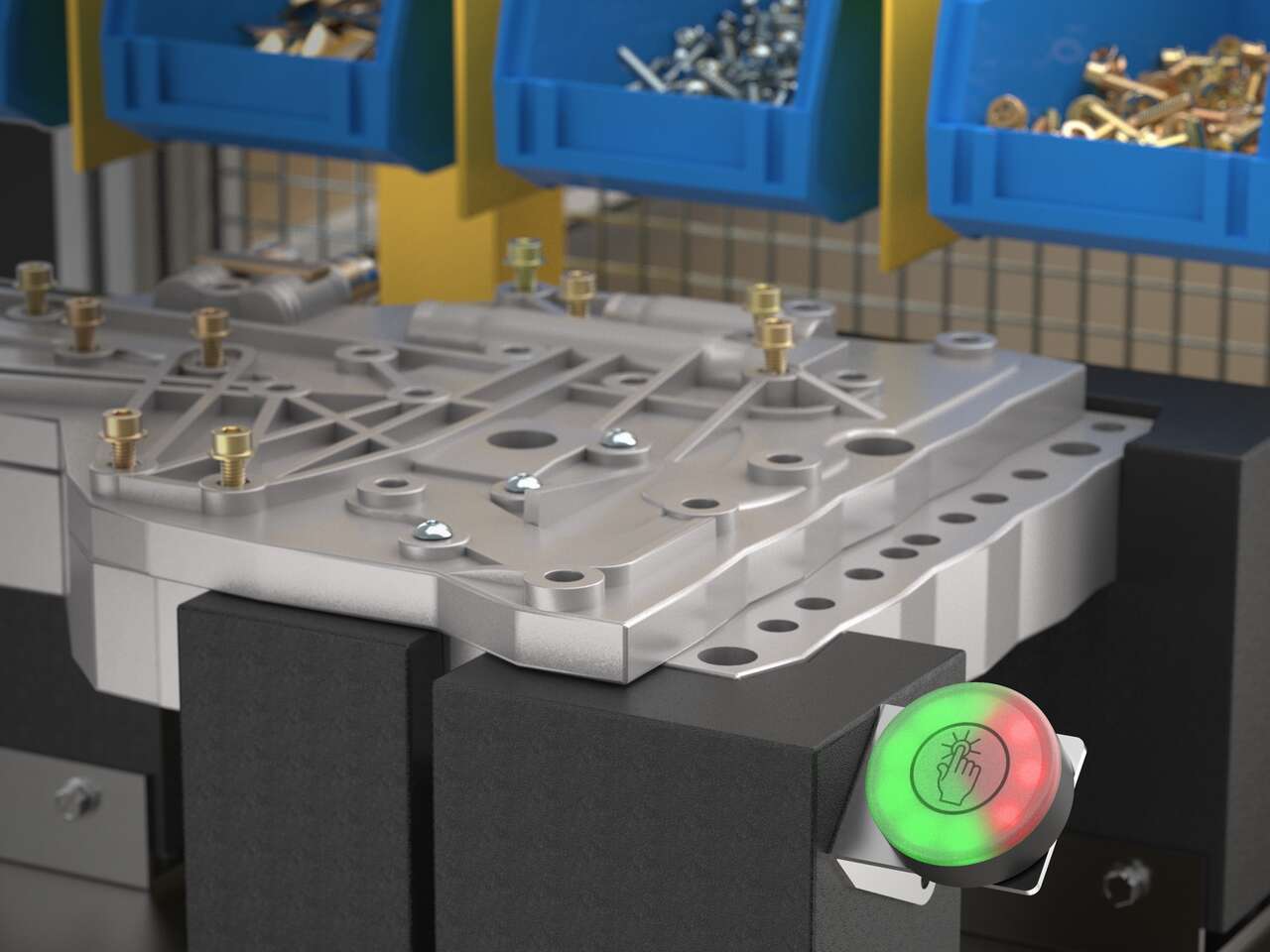

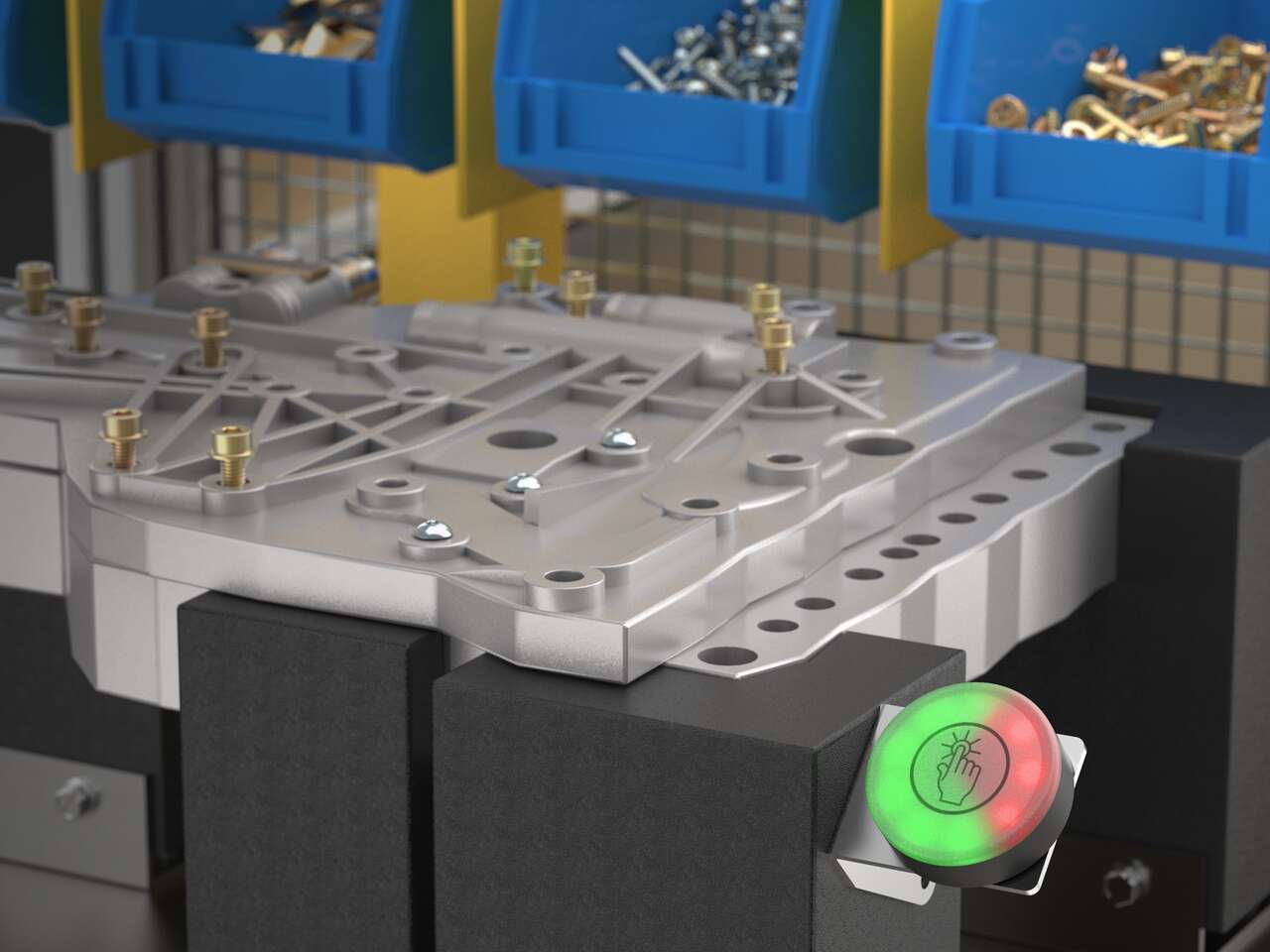

为组装流程提供更清晰的视觉反馈

用例:产距时间指示

- 可编程 LED 触摸按钮可用于指示装配过程中的产距时间。这种动态的可视化反馈有助于保持装配工有条不紊地工作,无需在工作时看别的地方即可了解经过的时长。

- 产距时间对制造商很重要,因为它代表匹配需求和最大化利润所需的生产速率。

- 使用兼容 IO-Link 的 K50 Pro 触摸按钮可确保操作员保持产距时间。

- IO-Link 型号包含序列模式,可以用作计时器。明亮的 LED 光源非常醒目,易于直接安装在用户视线之内,从而提高效率,减少工作时的分心。

远处可见动态状态

用例:储罐料位监测

- 操作员、物料搬运工和主管需要查看料斗中的产品水平。 但是,无法在整个工厂中都看到局部显示。

- TL50 Pro 塔灯通过按颜色编码的灯段显示料位,而且在整个工厂车间都可见,因而操作员可以对料位高/低警报快速做出响应。

- IO-Link 主设备根据用户定义的阈值,直接将激光测量转化为简单易懂的料位。

- 相关人员从远处也能查看料位状态。 若有警报,工作人员即可确定料位是太高还是太低,因而立即准备好应对相关情况。

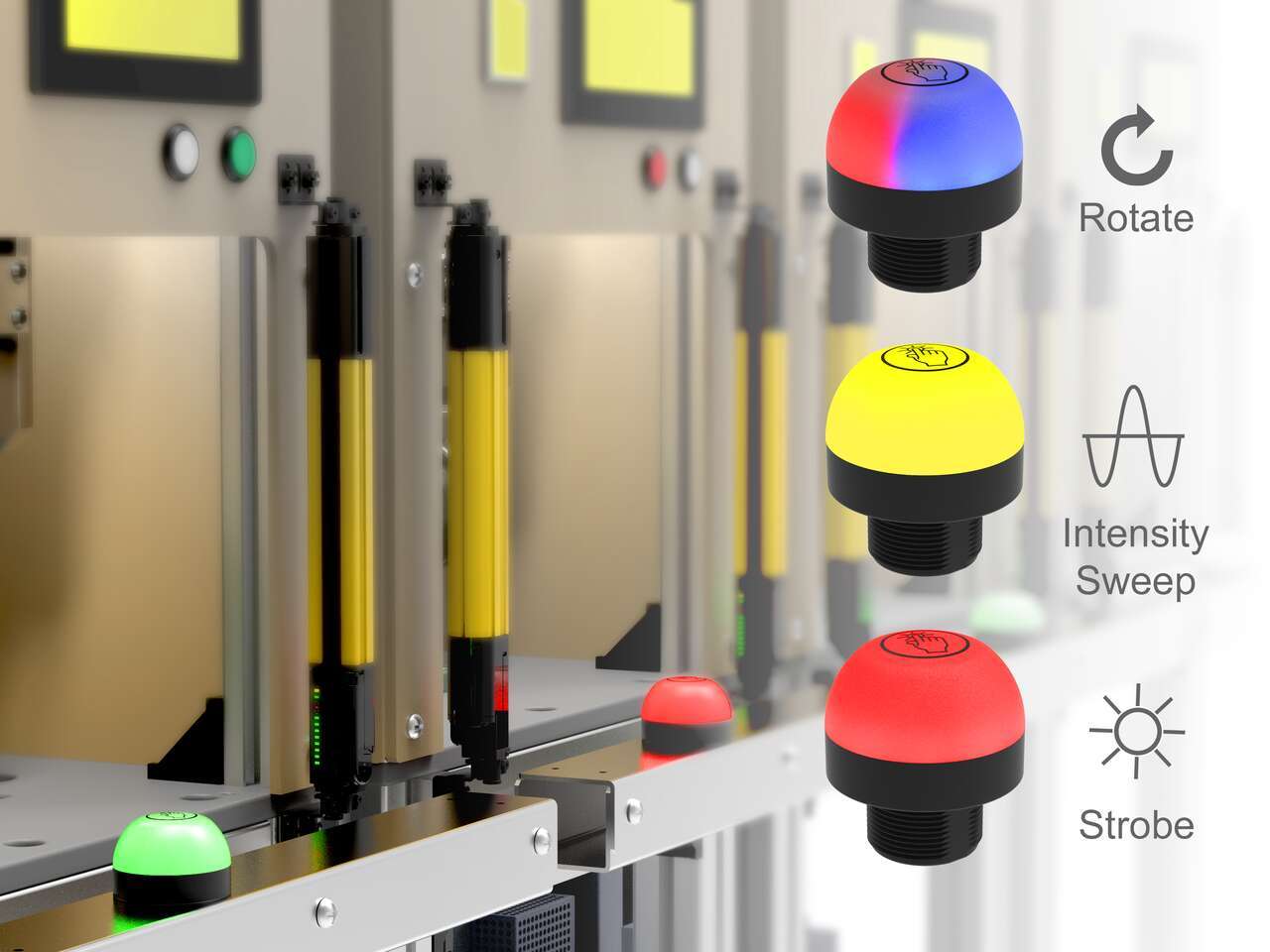

K50 Pro 系列

可编程多色指示灯

这款可编程的 通用型指示灯带 50 mm 圆顶或平面视窗,能更加醒目、更为明亮地指示状态。

- K50 Pro系列多色指示灯支持用户配置颜色、闪烁、调光和各种高级动画效果(如旋转、频闪、双色显示、双色旋转、双色闪烁和追光)。

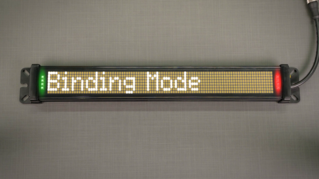

- 兼容 Pro Editor 的 型号支持用户在现场选择预定义颜色,无需 IO-Link 即可现场对设备编程。

- 配备 IO-Link 通信功能的型号 可实现几乎无限的定制指示能力。

- 少数标准化型号可在现场定制, 节省成本,降低库存要求

- 配备坚固耐用的 IP66、IP67 和 IP69K 聚碳酸酯外壳

- 布线简单,易于安装,节省成本

- 声音报警(可选)提供清晰、响亮的状态通知

K50 Pro 触摸按钮系列

可编程多色触摸按钮

K50 Pro 触摸按钮将成熟的触控技术、坚固的特点与 RGB LED 的多功能性融为一体。

- 明亮的 LED 指示灯与经由触摸激活的开关功能融于一体

- 坚固的 IP67 和 IP69K 级结构,适用于高压冲洗环境

- 采用人机工程学设计,操作时无需施力,减轻对手和手腕的应力

- IO-Link 型号拥有由主设备动态管理的 Pro 完整版功能,并为全面定制状态提供单独的 LED 控制

- IO-Link 型号包含序列模式,可用于指示级别和间隔时间等

配备 IO-Link 的 TL50 Pro 系列

可编程塔灯

多功能,独立的塔灯,通过将RGB LED提供的大量颜色选项与IO-Link通信提供的动态控制功能相结合,为用户提供几乎无限的自定义指示。

- 坚固耐用、经济高效并且易于安装

- 参数和过程数据选项可实现快速,完整的功能控制

- IO-Link可以完全控制颜色,闪烁,旋转和光线强度,以及高级动画

- 高可见性,一目了然的操作员指导和状态指示

- 支持多达10个光段,可选择额外的声音段

- 声音型号可提供标准,密封或全向声音段