用于制造和装配的拾取指示系统

用于精益生产的光导装配

拾取指示灯系统支持精益生产计划。 通过减少生产和装配过程中的人为错误风险,拾取指示是一种理想的poka-yoke(防错)解决方案。

拾取指示灯装置直观地引导人员以正确的顺序拾取数量适当的相应零部件。这就减少了错误和缺陷,并通过消除检查和重新检查指令等常见的时间浪费来源来提高生产力。

人工装配通常需要多个部件和多个步骤才能完成,而且每个步骤都有可能出现人为错误。 可能会从零件盒中挑选出错误的零件,或者以错误的顺序将零件组合在一起。 要确保高质量的最终产品,精度至关重要。 此外,制造商需要快速完成装配,最大限度提高产量。 我们面临的挑战,是在提高装配速度的同时保证质量。

为提高组装应用的效率和准确性,确保装配工人能够快速、轻松地识别下一个拣货位置非常重要。此应用能够明确识别装配工人要从中拣货的正确料盒,检测拣货是否已经进行,然后告知装配工人下一个拣货位置的拾取解决方案。

用户可以灵活地根据自己喜欢的操作程序进行选择。 技术可以适应您的流程。

适用于复杂流程的功能丰富的解决方案

在手工装配零部件并且需要各种不同零件时,常常会出错。零部件相似再加上难以遵循指令,可能导致生产过程中出现人为错误,从而拖慢整个过程并导致缺陷。

在多产品装配站使用拾取指示灯传感器可减少失误,加快装配速度,并简化培训过程。

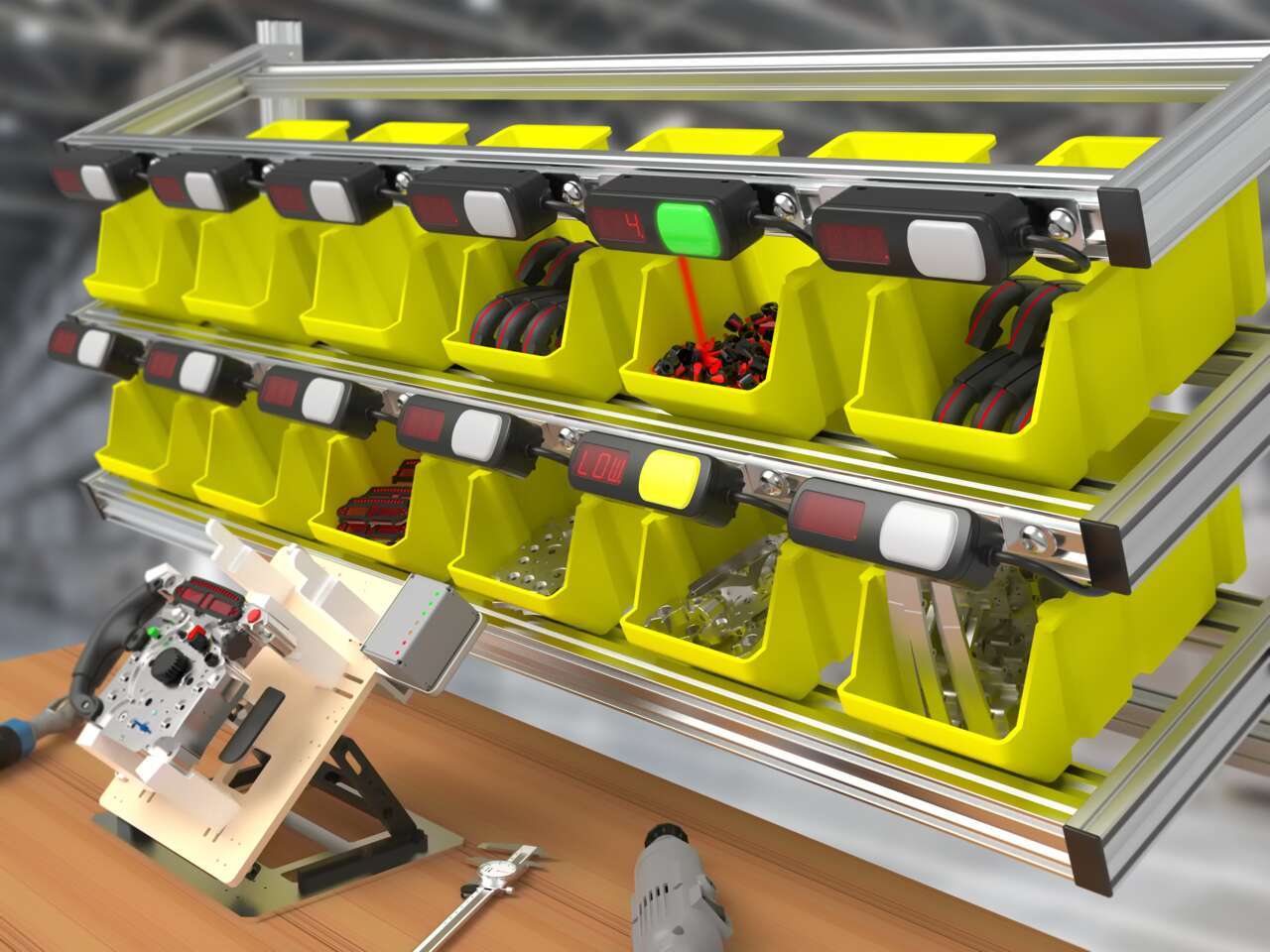

在该应用中,带有 LED 指示灯、光学传感器和字母数字显示屏的拾取指示灯装置为快速准确地完成复杂的装配提供必要的指导。 需要零部件时,LED 指示灯就会亮起,显示屏随之显示所需数量。 然后,光学传感器会识别出操作员何时拾取了部件。 每个步骤完成后,序列中的下一个拾取点就会亮起。

无缝拾取指示灯系统

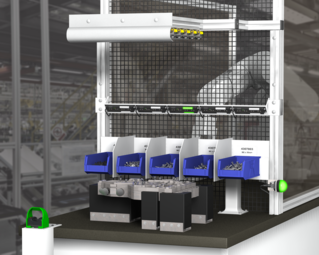

由于消费者需要各种各样的产品,生产流程变得越发复杂。制造商能够轻松地重新配置和移动装配站,从而真正实现提高生产效率和空间利用率的好处。

在这个应用中,无线K70拾取指示灯装置部署在便携式零件架上的料盒中。DXM100无线控制器通过点亮选定零部件对应的K70上的绿色LED指示灯来决定选择顺序。操作员选择零部件并触按K70按钮来确认操作。如果未按顺序激活,K70会变成红色,而黄色用于确认正确的过程。

无线连接允许装配站移动或重新配置,而无需重新布线。

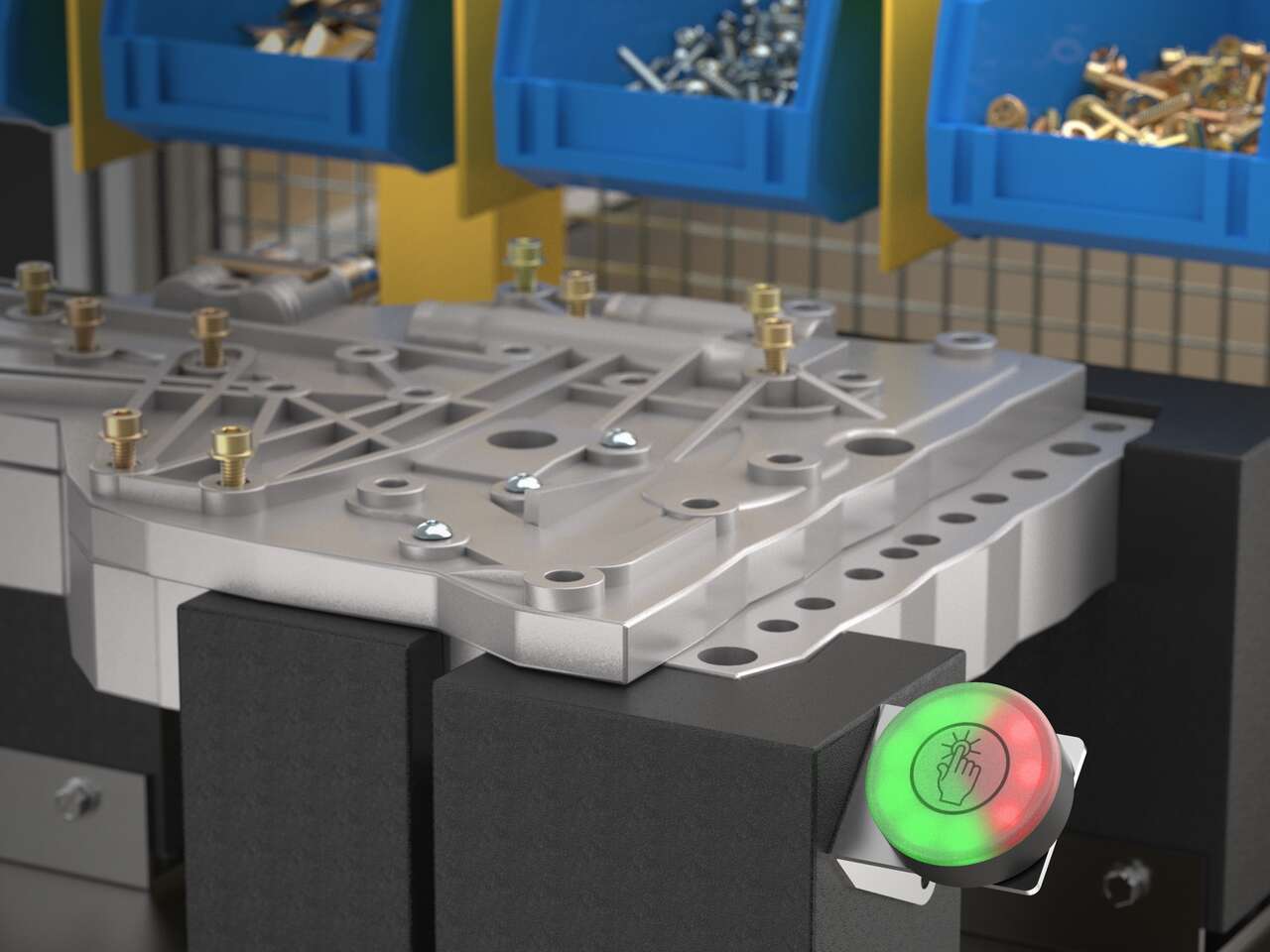

直观反馈帮助装配工人保持节奏

除了引导拾取,LED 指示灯还可以指示装配流程中的产距时间。 这种视觉反馈有助于保持装配工有条不紊地工作,无需在工作时看别的地方即可了解经过的时长。

产距时间对制造商很重要,因为它代表匹配需求所需的生产速率。保持生产速率相一致,是实现利润最大化的简单方法。

使用兼容 IO-Link 的 K50 Pro 触摸按钮可以很容易地确保操作员保持产距时间。IO-Link 型号包含序列模式,可以用作计时器。明亮的 LED 指示灯非常醒目,易于直接安装在用户视线之内,从而提高效率,减少工作时的分心。

可扩展型多功能拾取指示灯装置

PTL110 拾取指示设备是多功能指示灯,可选配触摸按钮、 光学传感器和三位数显,通过串联打造强大的拾取系统。PTL110 系统响应迅速,安装灵活,可提高拾取、套件制作及相关应用的速度、生产率和质量。

- 提供具备光学传感器和触摸传感器功能的型号。

- 选配的 3 位字母/数字显示可用于指示部件计数或提供其他指令。

- M12 连接器支持快速、安全地安装多个设备,无需额外布线。

- 指示器提供十四种颜色和多种动画功能,以此区分多种情况。

- 由 PICK-IQ™ 提供支持,这是一种专用的 Modbus 兼容串行总线协议,它使用通用 ID 来减少轮询多个设备所产生的典型延迟。

- 可与 DXM700 无线控制器配对,以便在推车和移动拾取站中部署。

无线触摸按钮

Wireless K70 Indicators are bright, 70 mm multicolored indicators offering increased communication possibilities and greater versatility in deployment.

- 70 mm diameter with 30 mm mounting base

- Models are available with up to five colors in one device

- Rugged, water-resistant IP65 housing

- 12 to 30 V dc operation

- Flashing input control

- SureCross wireless node built into the base

- 900 MHz and 2.4 GHz wireless options

- Binds easily to a Gateway

- Input wires can be configured as auxiliary sourcing inputs from external devices or as a 20 Hz, 32-bit event counter