精密测量

解决公差严格的应用需求

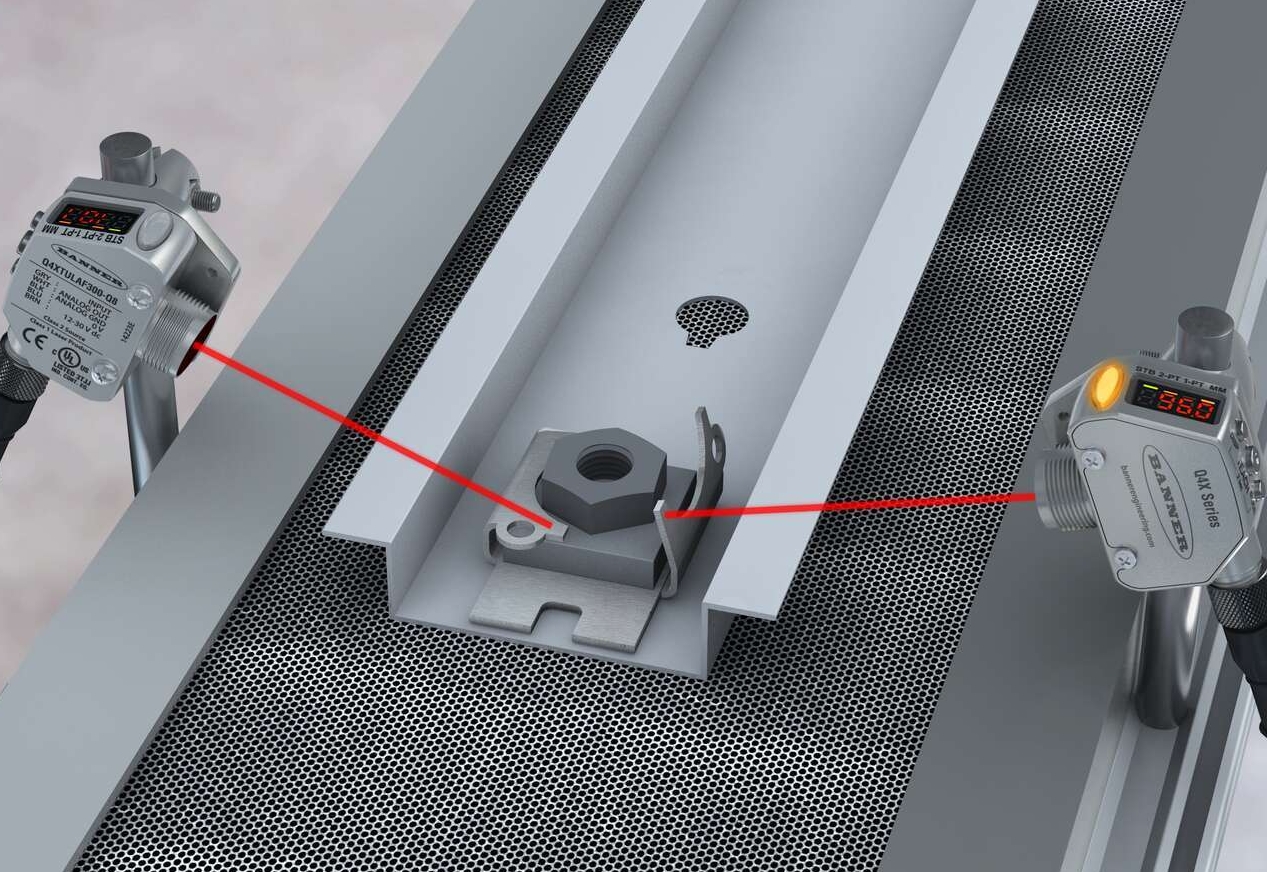

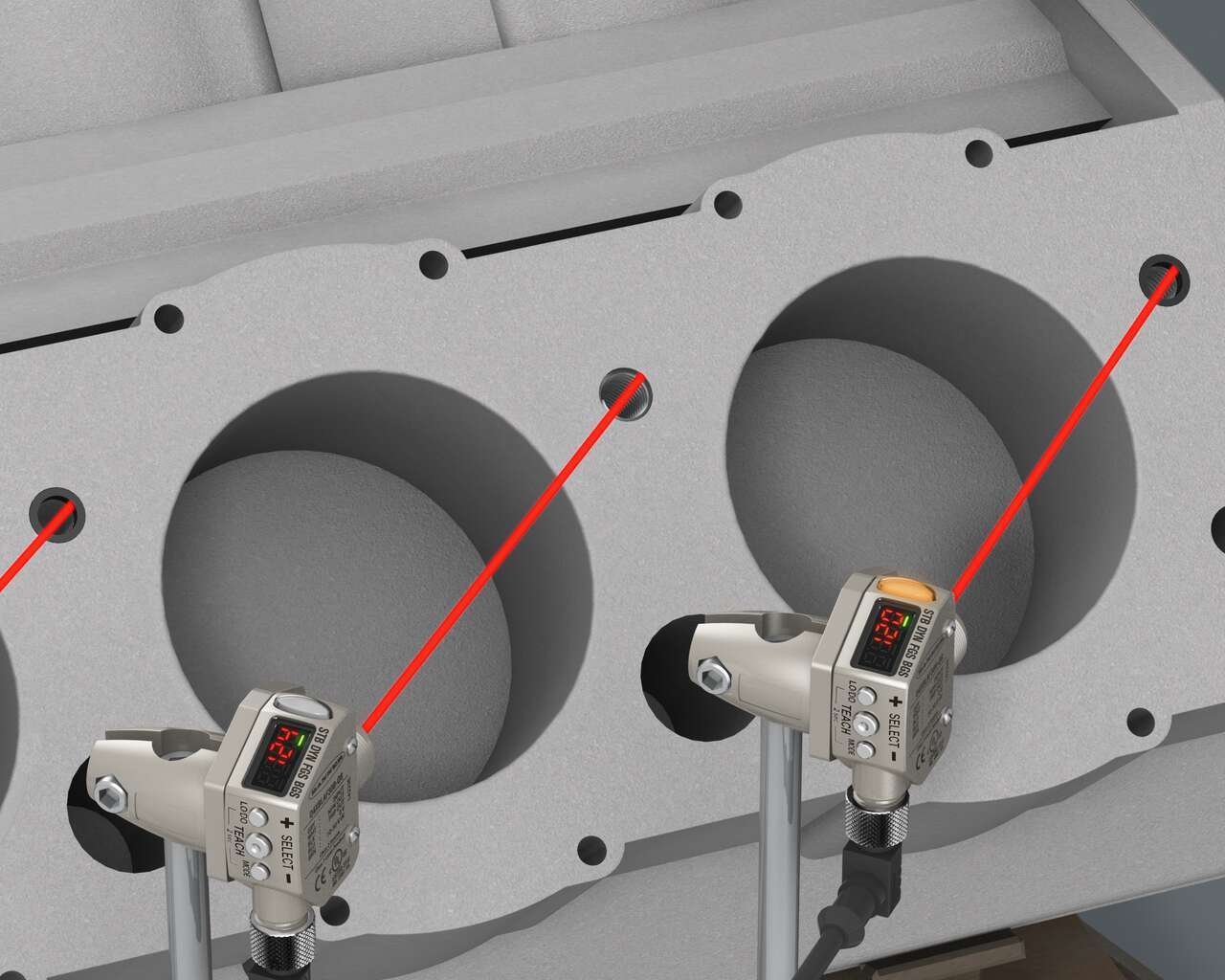

精密测量应用或许是很难解决的应用。 在极其严格的公差要求下,需要采取一种能够测量微米级零件的可靠解决方案,以检测零件尺寸、厚度、方向、放置等方面最为细微的变化。

确保零件符合严格的质量标准有助于减少下游问题,并降低由于零件缺陷而召回产品的风险。

并不是只有分辨率才重要

在精密应用中,微米级测量必不可少。 不过,尽管分辨率对于精密应用非常重要,但分辨率规格只代表传感器在“最佳情况”下的性能。

鉴于此,分辨率规格往往无法全面反映传感器的实际能力,有时甚至夸大传感器的性能。

因此,结合考虑分辨率规格与传感器性能的其他指标很重要。

在离散检测应用中,考虑传感器的可重复性(传感器在相同条件下再现相同测量结果的可靠程度)和最小物体间隔(为进行可靠检测而必须将目标与背景隔开的最小距离)也很重要。

对于模拟应用,重要的是要同时考虑传感器的分辨率和线性度(模拟输出在整个测量范围内接近直线的程度),以确保在整个传感器范围内都能获得可靠输出。

结合分辨率后,这些附加规格更能全面反映出传感器的实际性能。

实际目标与温度波动

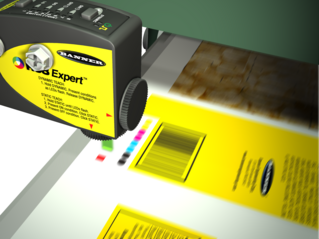

现实世界中的目标往往难以进行一致地测量。在不同的行业和应用中,被测物体可能非常暗(反射率低)、非常亮(反射率高)或存在多种颜色过渡,所有这些都会大大影响测量的可靠性。

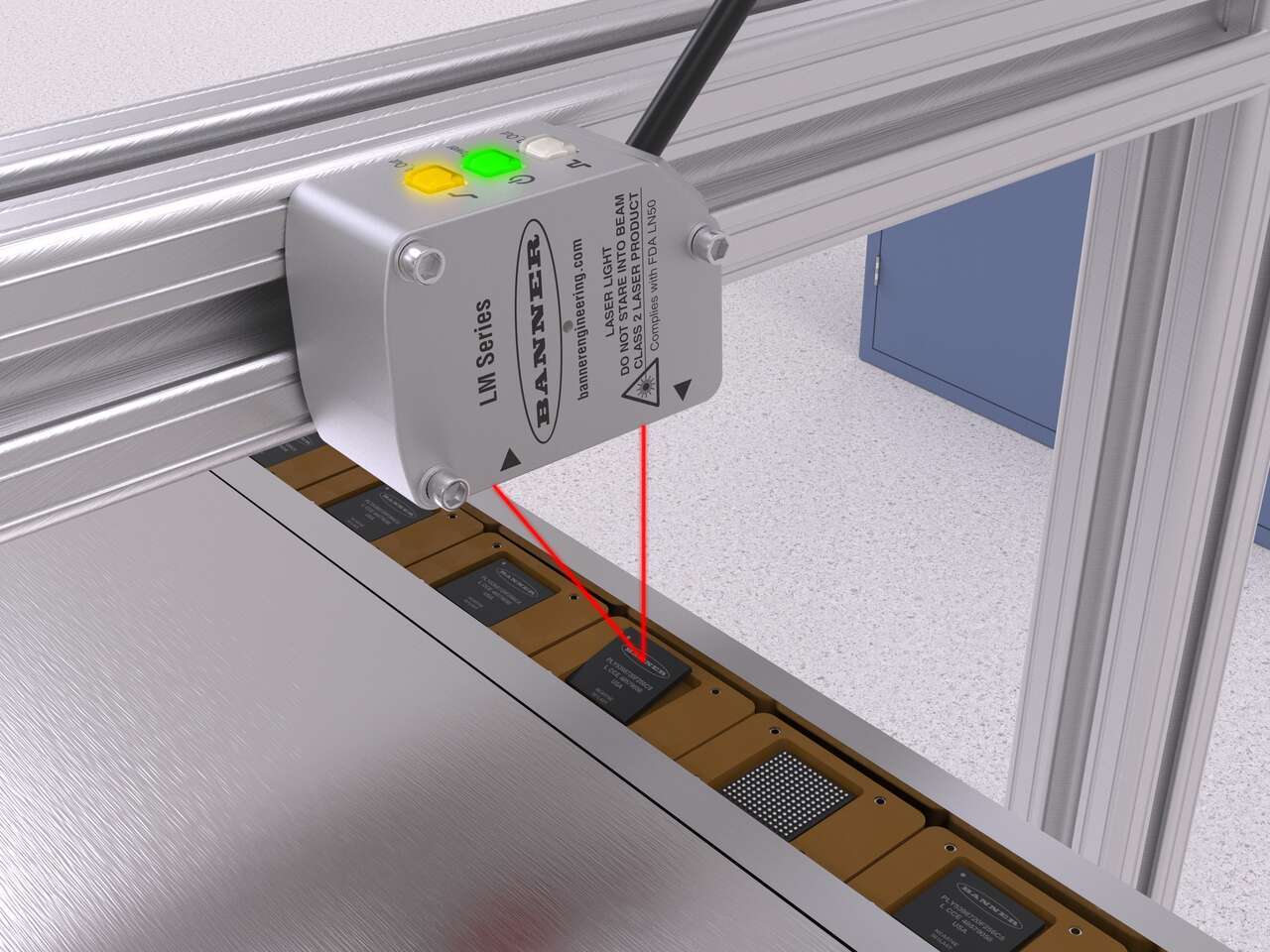

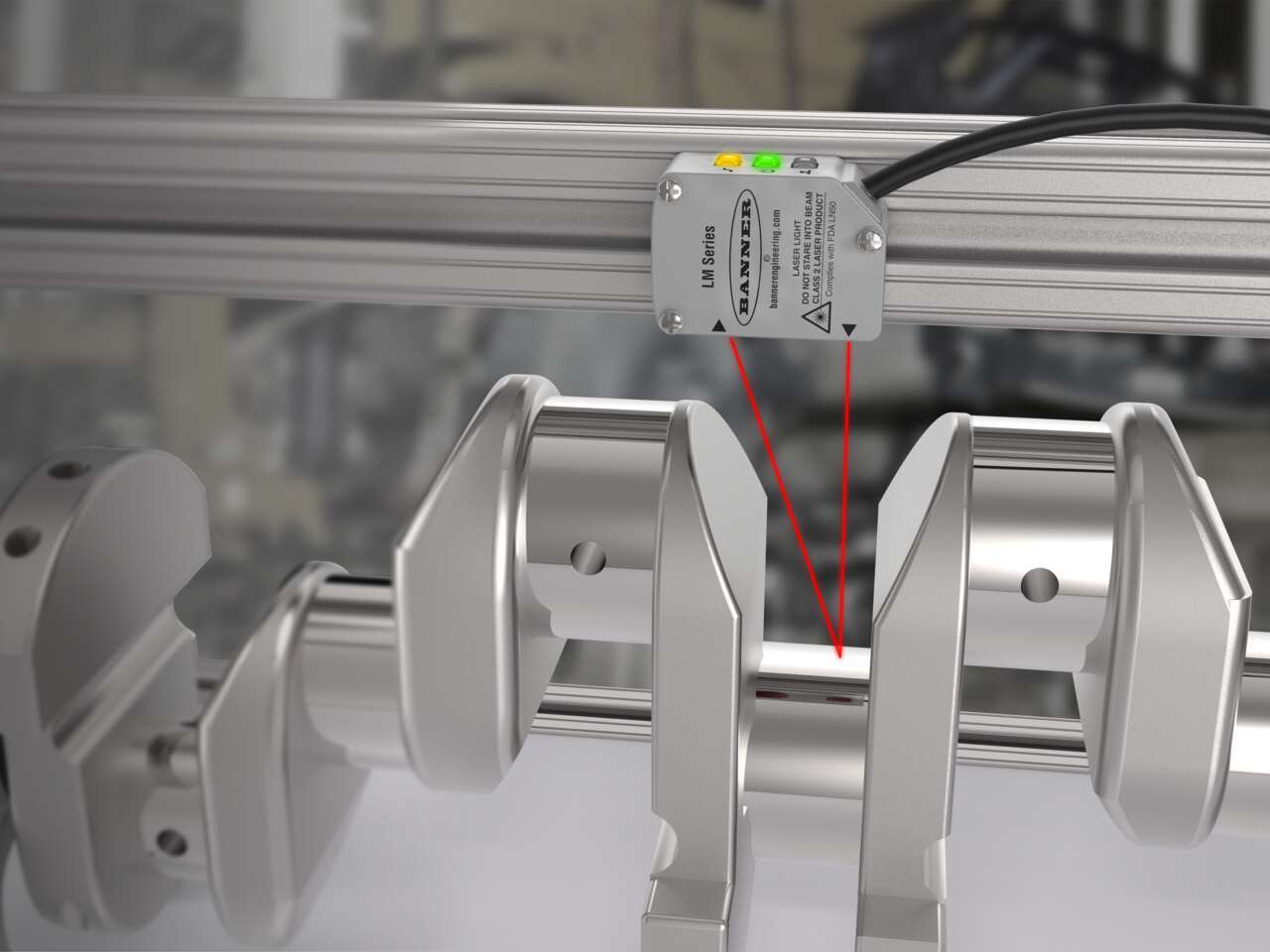

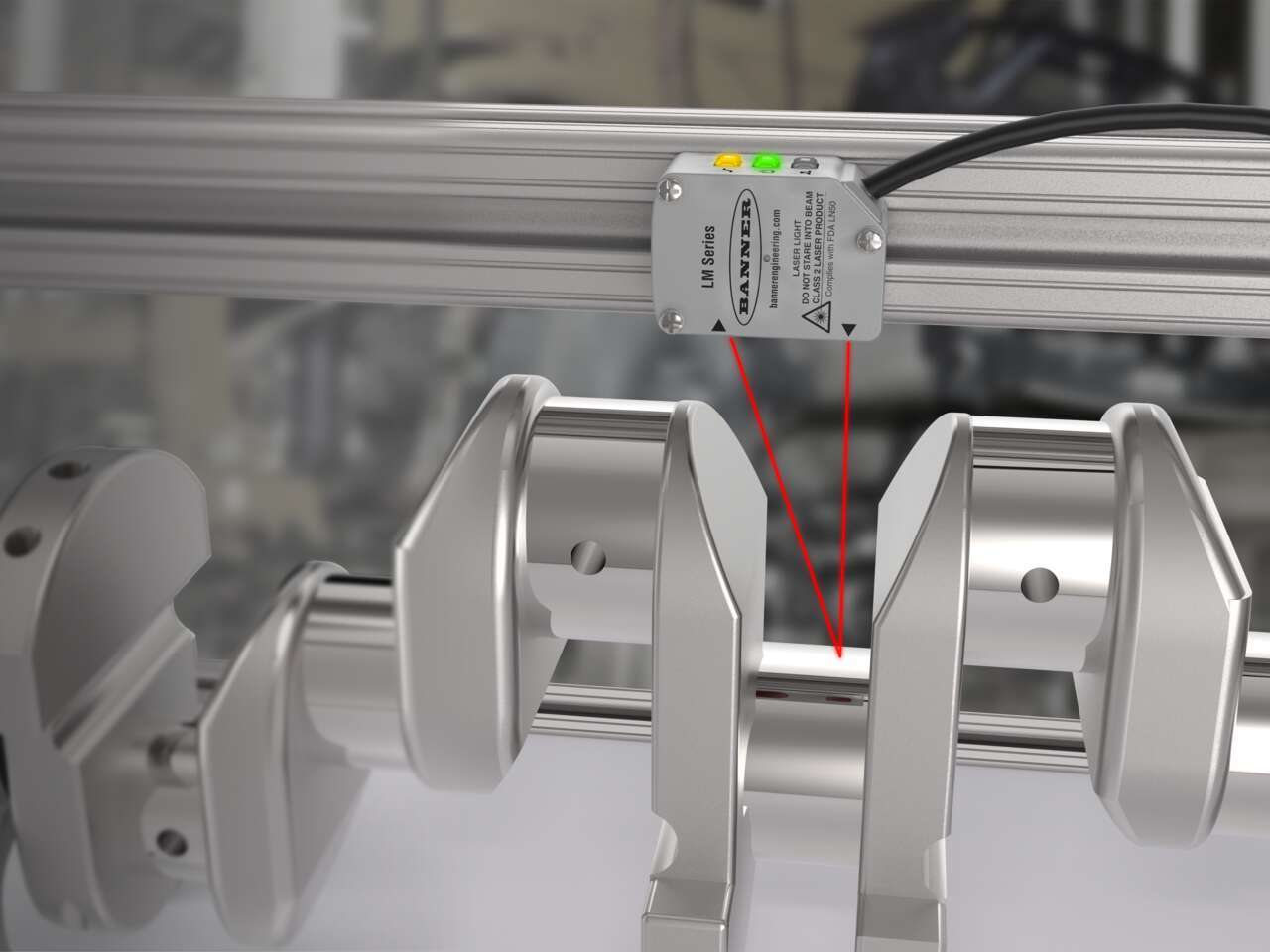

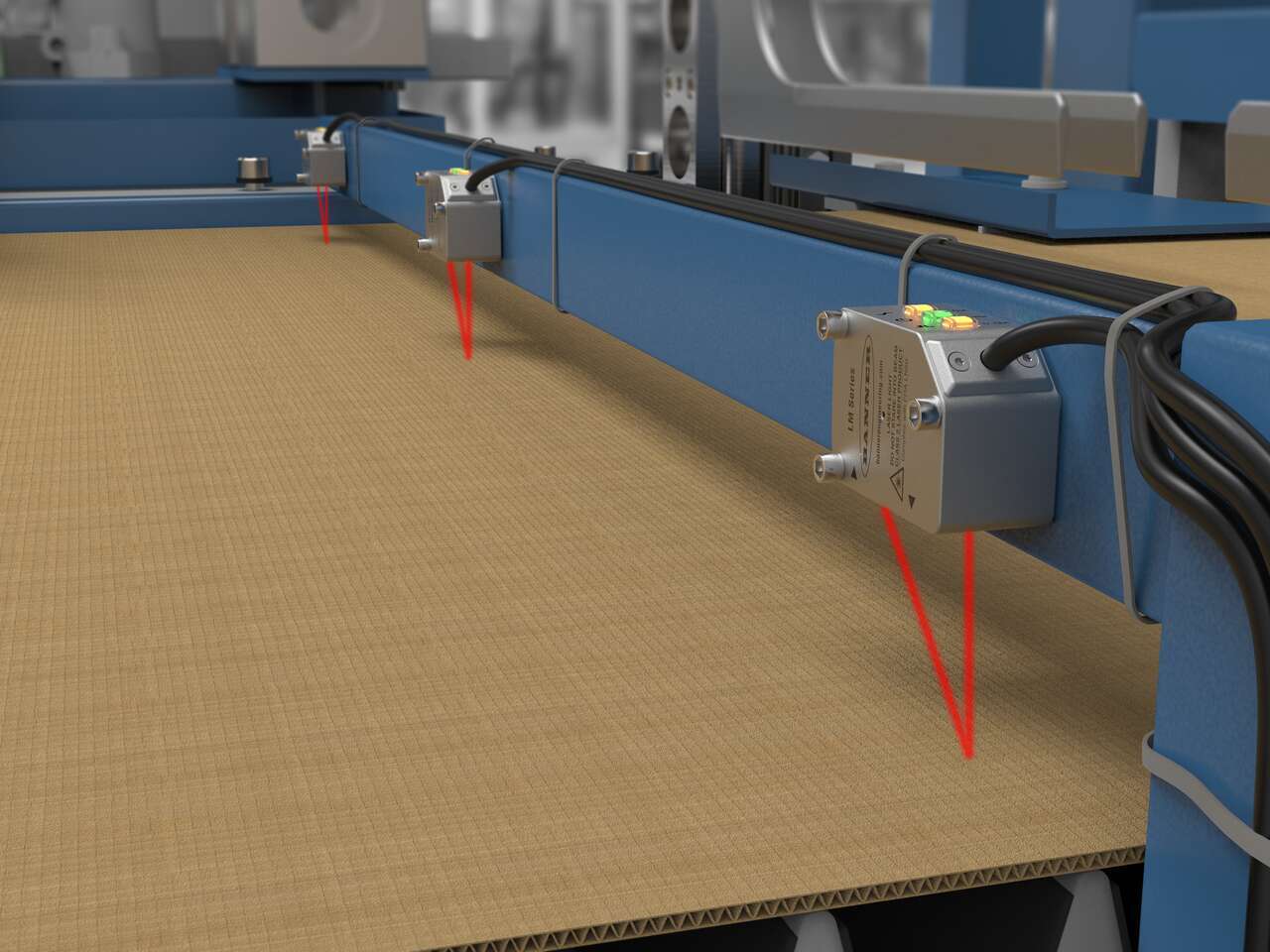

为缓解这个问题,某些激光测量传感器(例如 LM 系列)提供自动增益调整功能,这意味着传感器会根据目标的反射率动态增减其功率。这样能确保可靠测量各种颜色和反射率的目标。

环境温度变化也会极大影响精度测量。对于某些传感器,全天当中温度上下波动几度也可能导致传感器的测量误差翻倍,精密传感器的优势消失殆尽。因此,必须选择在任何周围温度下都具备高度热稳定性的传感器,才能进行可靠测量。

远程配置与监控精度

最后,选择正确的配置和安装方案有助于确保传感器精度。

安装稳定性对于精密测量传感器至关重要。即使采用最佳规格,如果没有牢固安装精密传感器,也无法可靠测量。为降低测量误差风险,请务必将传感器牢牢固定在安装夹具上,并避免受到过度振动。

通过 IO-Link 或邦纳的 RSD1 远程传感器显示屏进行远程配置和监视,无需直接按设备上的按钮即可配置传感器。这降低了按钮动作干扰传感器精度的风险。

用户利用远程配置和监测选项还可以从传感器收集运行状况和性能数据,便于制造商预测维护需求并做出数据驱动型决策。

善于解决问题的激光测量传感器

坚固耐用的多功能型激光测距传感器性能卓越,能够检测出亚毫米级的距离变化。

- 开关量,模拟量(0-10 V或4-20 mA),透明物体检测,可提供IO-Link型号

- 可靠的检测范围,近至25毫米,远至610毫米

- 根据距离检测各种各样的目标颜色、材质和表面

- 双示教模式(强度+距离),是防错应用的理想选择,可实现透明物体检测,无需反射板

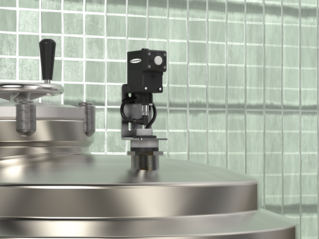

- 坚固耐用的FDA级不锈钢外壳,防护等级达IP69K