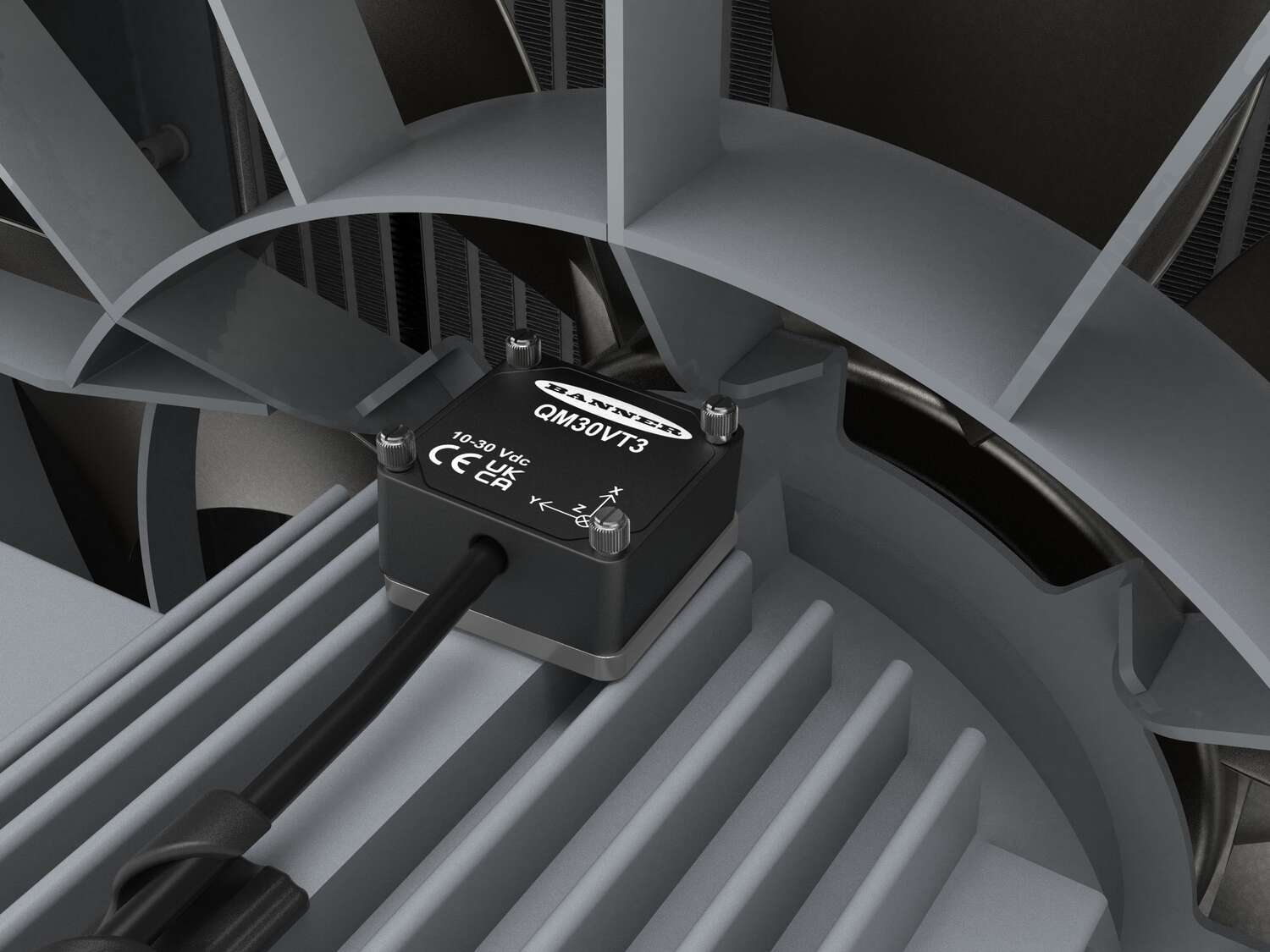

QM30VT3 3-Axis Vibration Sensor

QM30VT3 3-Axis Vibration Sensor with VIBE-IQ machine learning enables predictive maintenance, real-time alerts, and Modbus integration to prevent downtime.

Whether you choose a 2-axis or 3-axis solution, modern vibration sensors continuously measure machine vibration across one or more axes—typically capturing parameters like velocity (RMS or peak), acceleration, kurtosis, and crest factor at bandwidths reaching into the kilohertz range.

无论您是选择 2 轴还是 3 轴的解决方案,现代化的振动传感器都能连续测量机器一条或多条轴的振动,通常能以千赫兹级别的带宽捕获速度(RMS 或峰值)、加速度、峰度和波峰因数等参数。将这些传感器安装在关键部件(如电机轴承)附近,能够准确检测出不平衡、不对中、轴承磨损以及其他机械问题的早期迹象。它们会实时收集数据,并通过 RS-485 Modbus 等标准协议或无线连接进行访问,为维护团队提供实用的洞察,主动监测机器运行状况。