监测移动式滚筒中的料位

客户要求:监测便携式滚筒中粘合剂的液位,防止溢出

解决方案:K50U 无线超声波传感器、TL70 无线塔灯、DXM 无线控制器

为何选择邦纳?多功能移动式解决方案 - 无线产品可轻松适应变化的楼面布置,不会中断工作流程

带给客户的优势

减少流程中断 - 根据液位状态的实时结果主动实施工作,避免花费时间清理溢出的粘合剂

非接触式解决方案 - 不接触液体,不会在传感器上留下任何残留物或积聚物,也不影响传感器功能

背景

某全球电子制造商在组件中使用的高粘度环氧树脂滚筒液位方面遇到了问题,因此转变为使用自动化产品解决方案。便携式滚筒中装有粘合剂材料,这些粘合剂将用于常常需要重新布置的生产车间。员工开始往滚筒中灌装,然后就走开了,因为粘合剂流速缓慢,每个滚筒需要很长时间才能加满。但这种情况下很容易出现问题,因为员工容易忘记很多滚筒在进行灌装作业,导致溢出。随之而来的清理和维护很麻烦,甚至会成为大问题。这就需要一种能够监控液位并在导致一片狼藉之前将液位状态告知于操作员的解决方案。

挑战

这种特定类型的液位监测应用很难找到解决方案。筒内的液体又粘稠又硬,难以进行可靠的检测。滚筒还需要具备便携和无线功能,因为它们会经常移动。楼面布置会随仓库的要求而变化,每个滚筒都需要方便地运送到较大的储罐处进行灌装。这些储罐利用重力来为滚筒进行灌装。便携式滚筒使得有线解决方案难以成行,并且最好能减少电缆敷设。

在员工忙于处理其他项目之时告知员工液位状态,可能会在繁忙的仓库和装配区带来一些问题。这类环境很容易变得忙碌,声音响亮的机械装置会产生环境噪声,因而难以提供指示。这就需要可靠且有效的指示,以防止出现错误和环氧树脂溢出。

解决方案

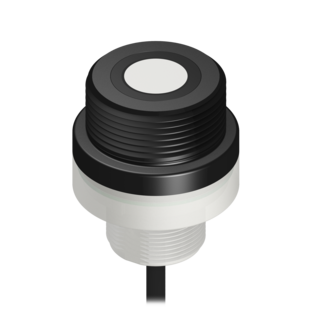

将邦纳 K50U 系列无线超声波传感器固定在滚筒上方,并同步 DXM 系统,即可进行无线料位监测。这些传感器专门针对监测远程和移动式储罐及滚筒而研发。超声波传感器指向下方,并使用声波准确检测表面水平。用它可以测量从传感器到目标的距离。这对于粘稠而且缓慢移动的物质效果很好,因为声波不会轻易因不断移动的表面或反射光而中断。

它采用坚固耐用的设计,能够承受苛刻的环境,防护等级为 IP67 和 NEMA 6P。传感器配备集成的 5 针快速断开功能,可轻松连接至由电池供电的无线节点。电池供电的节点为传感器供电,容易部署和安装。其检测范围为 300 mm 至 3 m,非常适合于检测液位。使用无线产品时,无需敷设长电缆,而且适应各种各样的布置和应用。设置较短的采样率可以延长电池寿命。

内置无线连接功能的 TL70 塔灯是一种多合一解决方案,可以将液位状态告知于在仓库中的操作员,这样在往滚筒中缓慢灌装时,他们就可以继续处理其他任务。70 mm 大型灯段由两排明亮的 LED 组成,与顶部照明相比显得格外醒目,但在熄灭状态下呈灰色,有助于消除错误指示。TL70 塔灯还提供声音警报,尤其是在周围声音嘈杂的区域,可进一步提醒操作员。