防错和纠错

精益生产环境下的防错

防错是指在源头而不是在生产线上防错,避免流程中出现缺陷。

防错又称 Poka-Yoke(在日语中意为防误防错)。Poka-Yoke 设计通常用于在操作员即将犯错之时向其发出警告或完全防止犯错,以避免人为错误。Poka-Yoke 设计几乎可以完全杜绝操作员犯错的可能。

从源头防错可以防止问题在下游加剧,因此能显著提高生产力。

杜绝浪费

从源头检测质量

通过防错可以在错误和缺陷进入下一生产阶段前进行检测,从而将质量控制提升到新的水平。 防止缺陷从生产流程中的一个阶段进入下一阶段,可避免浪费时间和资源来处理缺陷零部件。

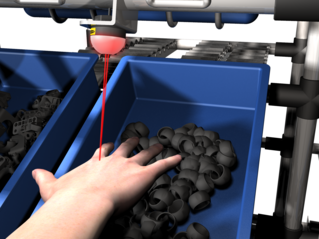

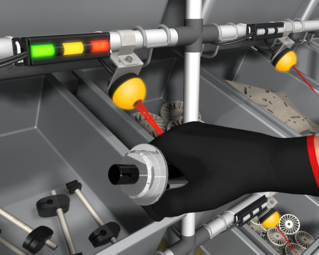

在零部件拾取等 手动流程中,视觉警告会使用彩色和/或直观显示效果的指示灯清晰地向操作员指示其操作正确与否。 光导组件便是使用视觉指示进行防错的好例子。

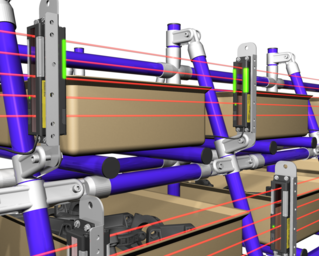

而在自动化流程中,则可以使用传感器和视觉系统等防错解决方案,确保在流程继续前解决问题。

邦纳提供传感器、视觉和光导解决方案用于防错,帮助制造商提高效率和质量,减少停机时间。 继续阅读以了解更多信息,或与我们联系以讨论您的具体应用。

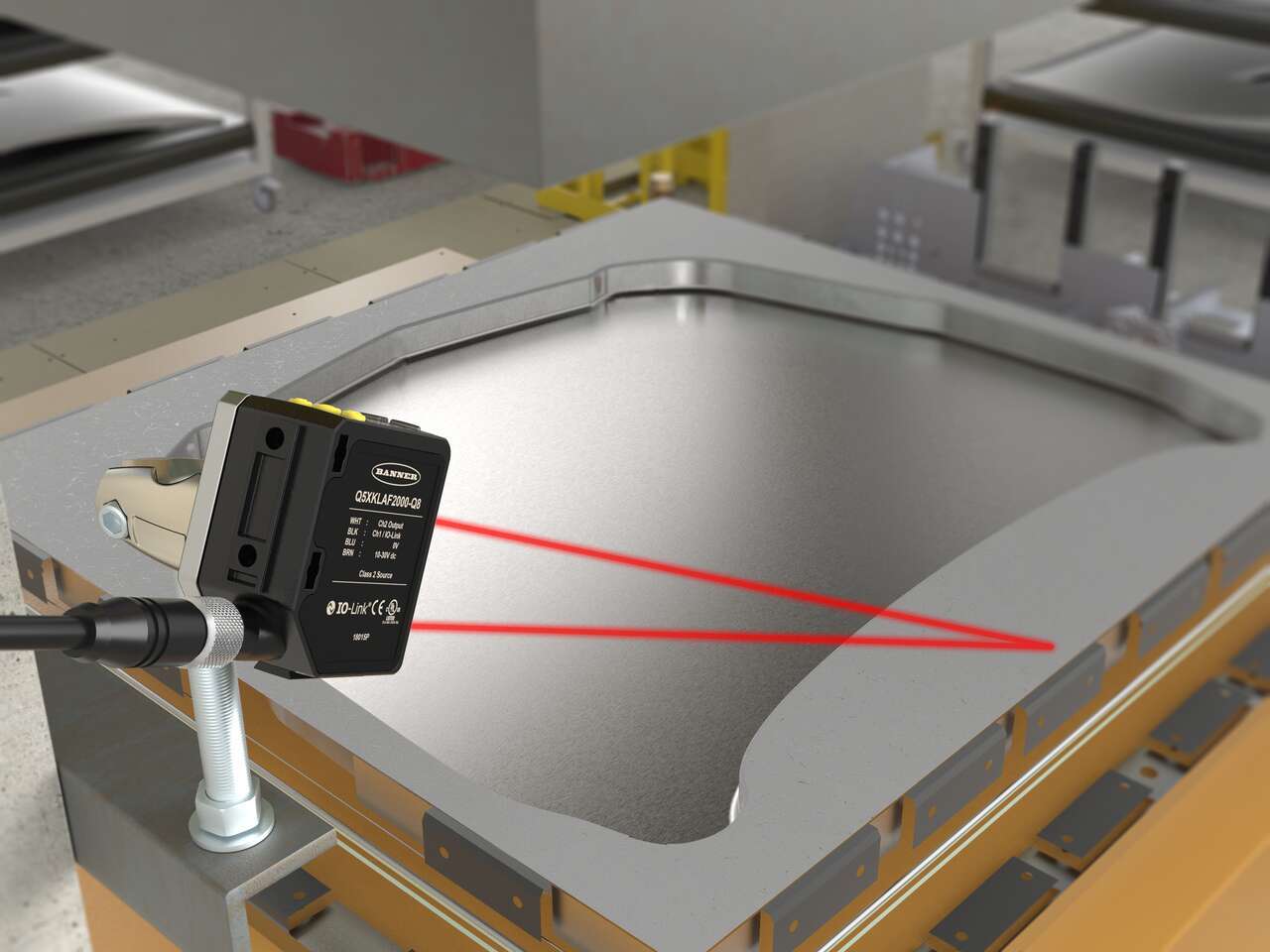

防错用传感器

- 激光测量传感器通常是可靠的防错应用解决方案。

- 邦纳激光传感器可检测和测量最具挑战性的目标,为制造商带来值得信赖的防错解决方案。

- 例如,在金属冲压应用中,重要的是在冲压之前确保金属板在冲压机上正确分度,以避免材料浪费和损坏冲压模具。

- 即便是处于锐角的反射目标,Q5X 系列激光传感器也能可靠检测。

- 在传感器验证材料前缘,并确认金属板存在而且进行了正确分度后,压机才会运转。

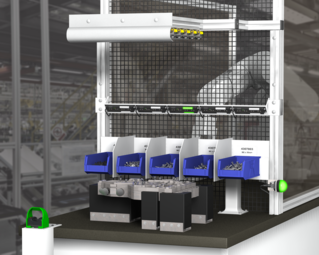

防错用视觉解决方案

- 在某些应用中,视觉解决方案可能是防错的不二之选。

- 例如,在汽车组装中,内饰件可互换,但颜色不同,因此很容易装错内饰件。 随着组装的进行,纠错变得愈发困难。

- iVu 彩色视觉传感器可验证饰条颜色是否与车辆制造顺序相匹配。

- 如果检测到错误(安装了颜色错误的饰条),则必须纠正该错误,才能进入汽车组装的下一步。

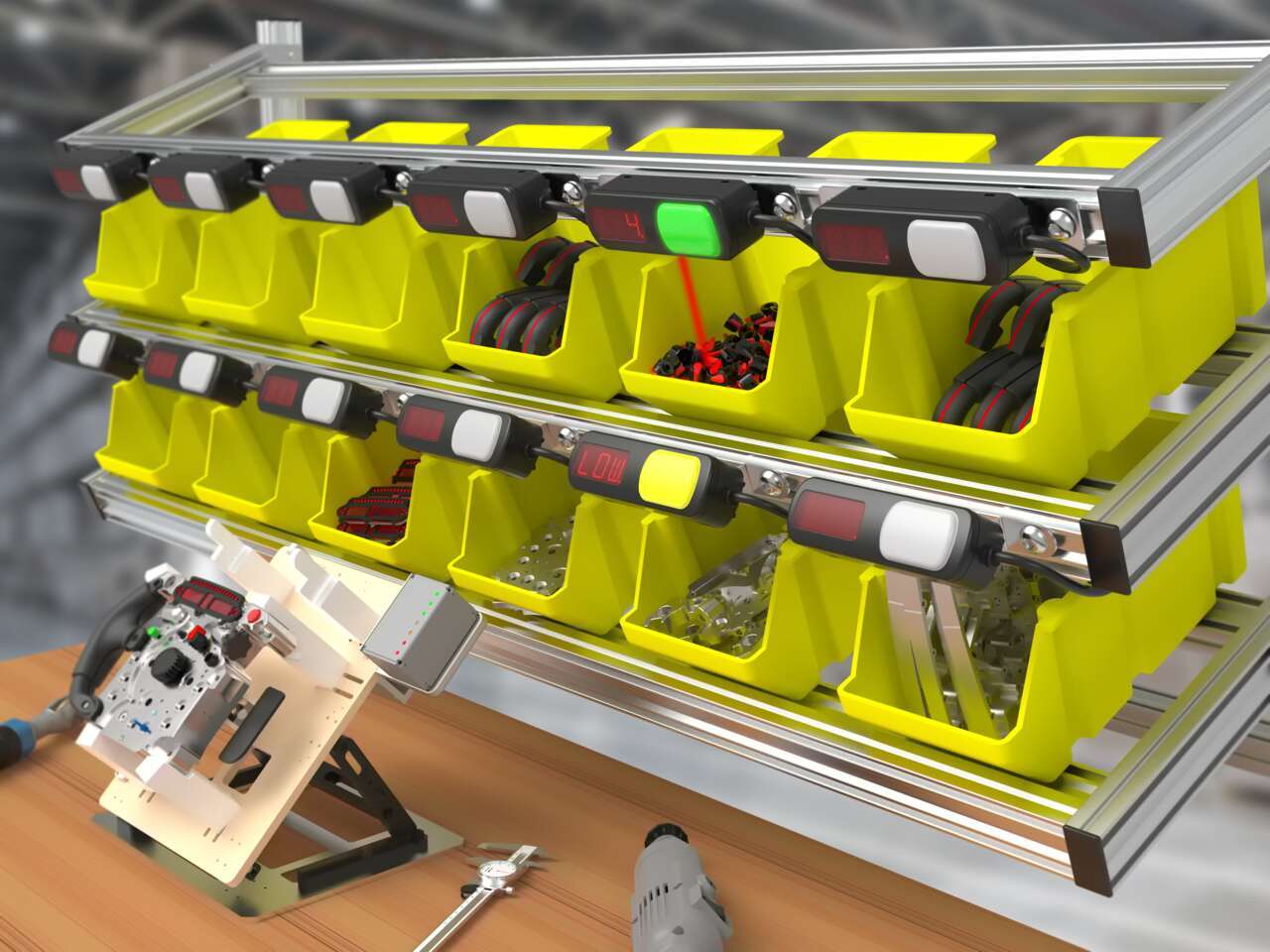

防错用拾取指示灯

- 组装过程中最常用的一种防错技术或许就是光导拾取,也称为拾取指示灯。

- 拾取指示灯设备使用彩色 LED 直观地引导组装人员以正确的顺序拾取数量适当的相应零部件。

- 这降低了人为失误风险,加快了构建速度,能在最大限度提高生产力的同时确保高质量。

iVu 系列

视觉传感器

iVu 和 iVu 彩色图像传感器用于监测零部件的类型、尺寸、方向、形状、位置、颜色或颜色变化。

- 一体化解决方案,包括相机、控制器、镜头和指示灯

- 使用 Vision Manager PC 软件、板载触摸屏显示器或远程触摸屏在短短几分钟内即可配置完毕

- 使用各种灰度或颜色工具进行多点检验

- 紧凑、坚固的外壳,防护等级达 IP67,配备各种颜色的集成环形灯,其中包括红色、蓝色、绿色、白色、红外和紫外灯

- 可互换镜头,包括 C 卡口,最大程度实现应用灵活性

- 以太网/IP™、Modbus/TCP、PROFINET®、PCCC 和串行 RS-232

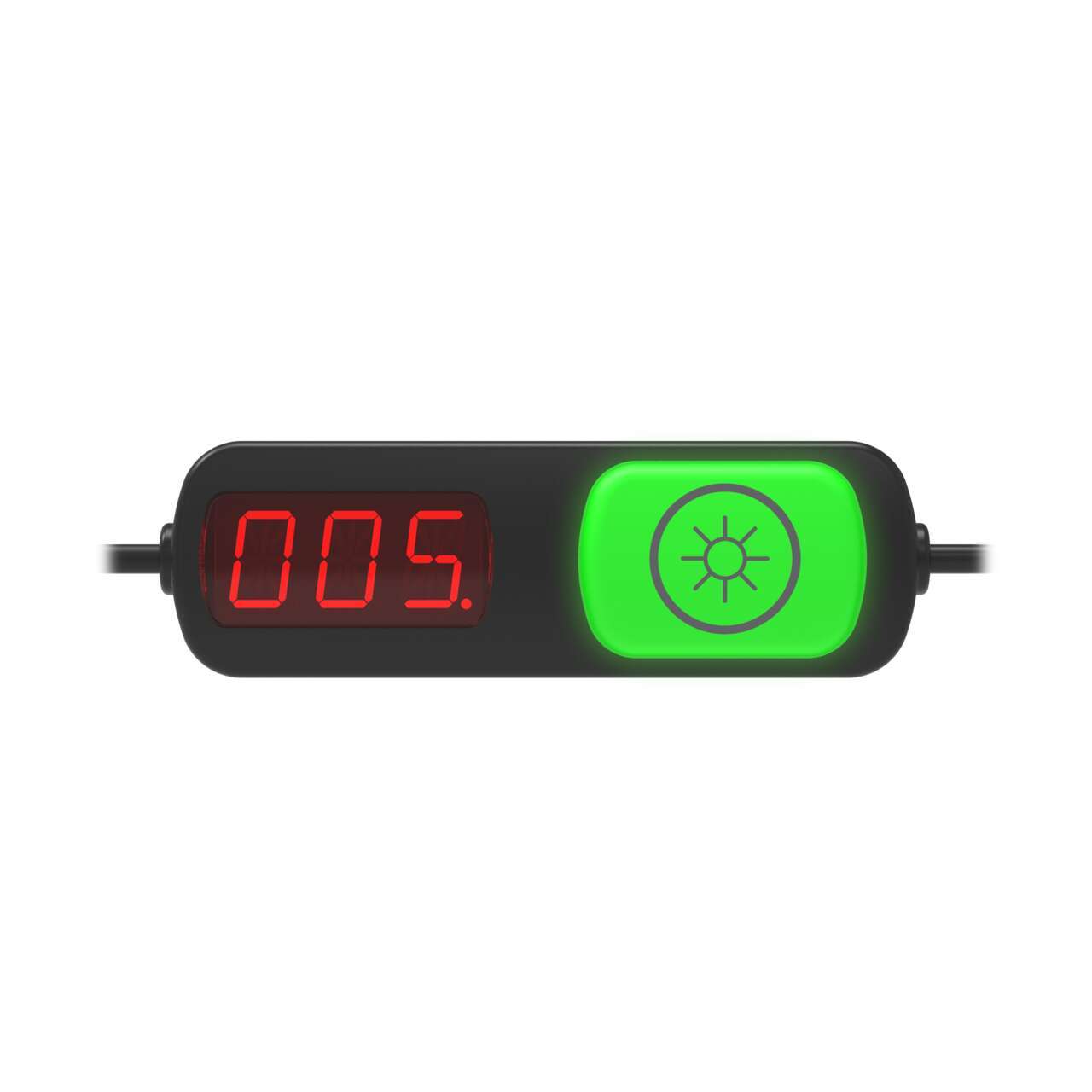

PTL110 系列

可扩展型多功能拾取指示灯设备

PTL110 拾取指示设备是多功能指示灯,可选配触摸按钮、 光学传感器和三位数显,通过串联打造强大的拾取系统。PTL110 系统响应迅速,安装灵活,可提高拾取、套件制作及相关应用的速度、生产率和质量。

- 提供具备光学传感器和触摸传感器功能的型号。

- 选配的 3 位字母/数字显示可用于指示部件计数或提供其他指令。

- M12 连接器支持快速、安全地安装多个设备,无需额外布线。

- 指示器提供十四种颜色和多种动画功能,以此区分多种情况。

- 由 PICK-IQ™ 提供支持,这是一种专用的 Modbus 兼容串行总线协议,它使用通用 ID 来减少轮询多个设备所产生的典型延迟。

- 可与 DXM700 无线控制器配对,以便在推车和移动拾取站中部署。