产品召回的跟踪和追溯

通过准确、及时的召回来减轻损失

任何制造商的一个重要目标是避免产品召回。 召回的成本很高,既包括维修、更换或回购的实际成本,也包括品牌声誉受损的成本。

实施质量控制解决方案可以帮助减少产品缺陷和安全隐患的风险;然而,即使是最有效的质量控制也不能消除所有风险。

召回发生时,制造商必须准备好通过确定受影响的产品并及时发布召回以减轻损失来迅速做出反应至关重要。

可追溯性取决于可靠的识别。

当召回事件发生时,制造商的反应会使其声誉受损,并进而影响客户的忠诚度和未来的利润。

制造商必须迅速采取行动,召回所有已经购买的受影响产品。在某些情况下,制造商必须能够从他们自己的货架、分销中心和零售机构快速拉出受影响的库存。 在其他情况下,就像许多汽车召回事件一样,消费者可能需要及时修复他们购买的产品。此外,为了防止不必要的成本,制造商必须避免无意中召回未受影响的产品。

跟踪和追溯解决方案帮助制造商快速、准确地执行召回,从而使受影响的产品能够被修复或从市场上撤下,问题能够迅速得到解决。

这些解决方案依赖于在整个供应链中对单个产品的可靠识别--最常见的是通过在从生产到购买的每个阶段扫描条码。 跟踪和追溯解决方案的可靠性取决于扫描代码的设备,因此选择适当的识别技术至关重要。

在整个包装过程中跟踪产品

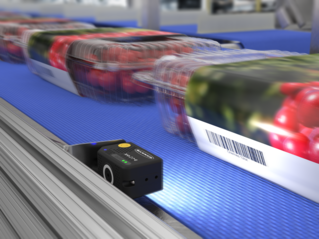

食品安全的跟踪与追溯

- 在食品包装中,条码被嵌入每个产品和生产运行的特定信息,以便在整个供应链中识别产品。

- 作为跟踪和追溯计划的一部分,包装厂在包装过程中的多个点核实产品条码,创建一个记录,使公司在召回时能够快速识别和隔离任何有质量问题的产品。

- 基于成像仪的读码器(如邦纳 ABR 3000),能够解码最广泛的 1D 和 2D 条码。沿着包装线部署,ABR 3000验证每个包装上打印的条码是否存在,是否可读,以及每个生产流程是否正确。

- 条码中包含的信息通过以太网连接发送到公司的生产管理系统,由该系统记录数据供将来参考。

读取不可见的UV条码以实现可追溯性

汽车零部件的跟踪与追溯

- 许多汽车供应商都采用紫外线(UV)条码来满足产品可追溯性和质量控制要求。

- 这项技术利用了一种紫外线油墨,条码只有在使用紫外线光源照亮时才能被看见。供应商可以将关键信息存储在直接印在组件上的小代码中,而不会影响设计的美观性。

- 在发生召回事件时,可以扫描代码以验证组件的安装和测试是否符合标准。

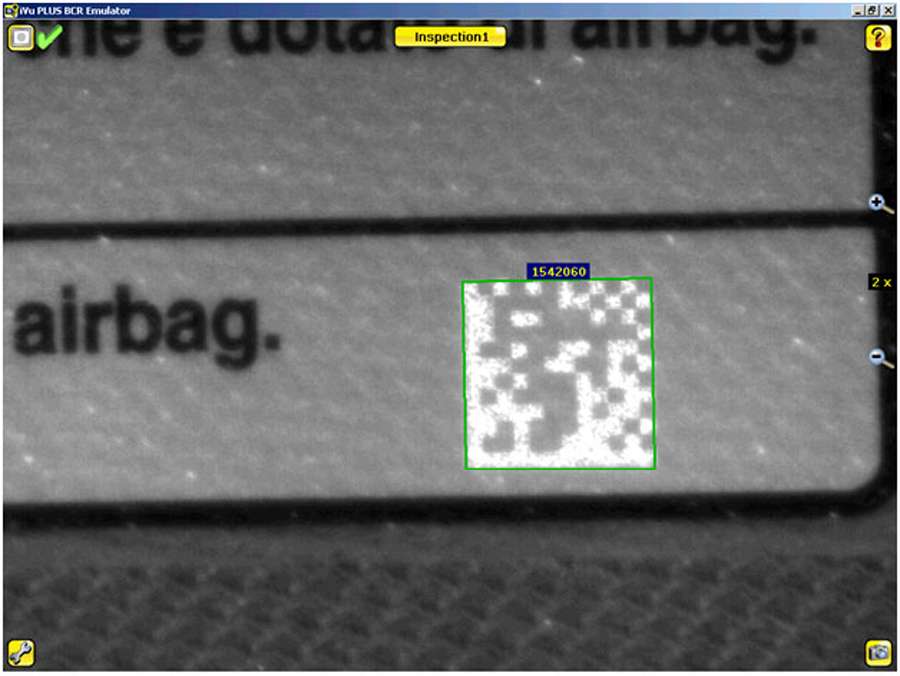

- 在这个应用中,,一个iVu BCR读码器 ,带有C型安装镜头、UV聚光灯和以太网功能,可用于读取不可见的二维Data Matrix码,并通过EtherNet/IP将数据发送到PLC,以进行防错和追踪。

验证代码是否贴在正确的产品上

药品包装的跟踪与追溯

- 只有当正确的代码被贴在正确的产品上时,可追溯性才会对促进召回有效。 因此,在发货前验证代码是至关重要的。

- 在制药业,医疗用品通常是单独包装在密封的小袋中。

- 在产品装运之前,必须对条码进行验证,以确保正确的条码贴在正确的产品上,以实现准确的可追溯性。

- 一个基于成像仪的读码器 ,验证每个条码,并通过以太网IP将数据发送到PLC,以便将来在召回时参考。

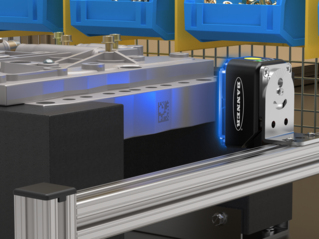

ABR 系列

基于成像仪的一维和二维读码器

abr 系列条码读取器的解码能力一流,能解决最具挑战性的跟踪和追溯应用。它们有两种紧凑的外形尺寸、多种照明配置、一系列分辨率和多种镜头选择。

- 读取完整的一维和二维条码库。

- 两种紧凑的外形尺寸,防护等级高达IP67,适用于工业环境。

- 分辨率高达200万像素,多种照明配置和镜头焦距(包括自动对焦),适合任何应用。

- 适用于高难度的应用,包括DPM 代码读取和偏振窗口

- 使用板载按钮或安装了功能齐全的 Barcode Manager 的电脑在短短几分钟内完成配置。

- 多种镜头选项,包括由软件调节的自动对焦,简化设置和配置。

- 通过工业以太网、串口和usb 进行配置,简化设备集成,收集工业物联网数据。

- 可在任何网络上远程监控、配置和查看统计数据的Web 界面

iVu BCR 系列

基于成像仪的一维和二维读码器

iVu BCR 系列条码读取器将强大的解码能力和使用便捷的特点融于一体,能解决高难度的追溯性应用。这些多功能条码读取器提供各种各样的镜头、照明和用户界面选项。

- 读取广泛的一维和二维条码,包括损坏、变形和其他难以读取的条码

- 能够在一次检测中读取任何方向的多个条码

- 使用集成的触摸屏、远程触摸屏或 PC 界面来设置、管理和监控检测

- 以太网和串行通信协议简化设备集成,实现工业物联网数据采集

- 坚固的 IP67 级外壳,是狭小空间和工业环境的理想选择

- 众多的集成照明选项简化了安装,优化了对比度

- 可更换镜头,包括各种标准选件和 C 型支架选件,能满足任何应用的需求

TCNM 系列

一维激光条码扫描器

TCNM读码器能够解码十几种常用的一维条码,可提供快速读取、宽景深和高分辨率。

- 读取十几种常用的线性条码符号

- 每秒完成500到1000次扫描

- 使用SMART-TEACH按钮和LED指示灯进行基本设置和诊断操作

- 条码重组算法结合多次扫描,即可重建损坏的代码信息

- GeniusPlus软件以及专有的内通信协议,在多个读码器设置中无需使用外部多路转换器

- 外壳坚固,防护等级达到 IP65