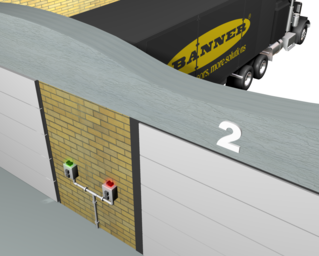

装卸区的车辆检测

提高生产力和效率

装卸区的车辆检测功能可以快速识别空闲的货位,在卡车到来时提醒工作人员,并在开门之前验证车辆是否处于正确位置,从而加快装卸时间。

这些功能有助于提高生产设施和仓库的生产力和效率。

应用:即使在恶劣的条件下,也需要使用可靠的解决方案来检测装卸区是否有大型卡车,并在开门之前验证卡车是否处于正确位置,以确保设施安全。

解决方案:QT50R 等高灵敏度雷达传感器使用调频连续波 (FMCW) 雷达技术,来确保在任何环境条件下都能可靠检测移动或静止的目标。 雷达是在户外环境中检测半挂车等大型目标的理想解决方案。

优势:雷达技术不受风、雨、环境光等天气条件的影响。 雷达传感器具有坚固的外壳,适合户外使用,减少了频繁维护或更换的需要。

应用:一家制造厂的装卸区需要检测装运卡车,以提高装卸区效率。当车辆抵达时,生产车间内的嘈杂声会导致难以迅速吸引员工的注意力。

解决方案:无线超声波传感器利用声波检测卡车何时到达仓库装卸区。 高能见度塔灯(如带声音报警功能的 TL70 塔灯)可以为工作人员提供视听警告信号,提醒车辆已到达并准备装卸。

优势:将无线传感器和指示器配对,就能在车辆到达装卸区时快速清晰地传达信息。 邦纳生产的坚固耐用的传感器可以承受恶劣的户外条件。

应用:装卸区出错和延误会导致整个供应链出现问题。识别装卸区的空闲货位,并在货物到达时引导员工前往正确的货位,可以缩短周转时间并减少错误。来自装卸区的绩性能数据可以帮助主管在人员配备、时间安排和设备分配方面做出更明智的决策,从而提高效率和性能。

解决方案:无线磁力计通过检测磁场变化来可靠检测车辆。 通过设施内的无线控制器可以无线发送状态信息。 控制器对每个货位处的抵达和离开情况进行计数,记录事件发生时间,并将任何状态变化转发给几个联网的塔灯中的某一个。

优势:日后可访问数据,并利用数据跟踪和改进周转性能、识别效率低下之处和流程问题,帮助主管对员工和设备做出更明智的决策。

雷达传感器

High sensitivity radar-based sensors ideal for collision avoidance on board mobile equipment, like reach stackers, forklifts, and mining vehicles.

- Fourth generation FMCW (true-presence) radar detects moving and stationary objects

- Higher sensitivity and longer range

- Adjustable sensing field — ignores objects beyond setpoint

- Easy setup and configuration of range, sensitivity, and output with simple DIP switches

- Sensing functions are unaffected by wind, falling rain or snow, fog, humidity, air temperatures, or light

- Sensor operates in Industrial, Scientific, and Medical (ISM) telecommunication band no special license required

- Rugged IP67 housing withstands harsh environments

无线地磁传感器

The M-GAGE sensor uses passive sensing technology to detect large ferrous objects, such as motor vehicles. The M-GAGE provides an alternative replacement for inductive loop systems and needs no external control box.

- Designed to minimize the effects of temperature change and fluctuating magnetic fields

- Sensor learns ambient background and stores settings in non-volatile memory

- FlexPower technology driven by a single, primary lithium battery integrated into the housing

- Transceivers provide two-way communication between the Gateway and Node, including fully acknowledged data transmission

- Fully potted and sealed housing contains the power source, sensor, and antenna for a completely wireless solution

无线超声波节点

The wireless ultrasonic sensor node is ideal for indoor parking applications.

- Can be mounted directly on the ceiling of a parking garage to identify the presence of a car in the parking space below.

- Detects objects up to 4 m away

- Integrated D-cell battery reduces the cost of installation by eliminating the need to run wires and conduit.

- Designed with temperature compensation via on-board temperature measurement

- Transceivers provide two-way communication between the Gateway and Node, including fully acknowledged data transmission

- Housing contains the battery, sensor, and antenna for a complete, robust wireless solution – IP67, NEMA 6