操作点的机器防护

防范作业点的危险

机器上的操作点是进行工作的地方。 保护操作点对于防止人员发生事故或受伤以及防止设备损坏至关重要。

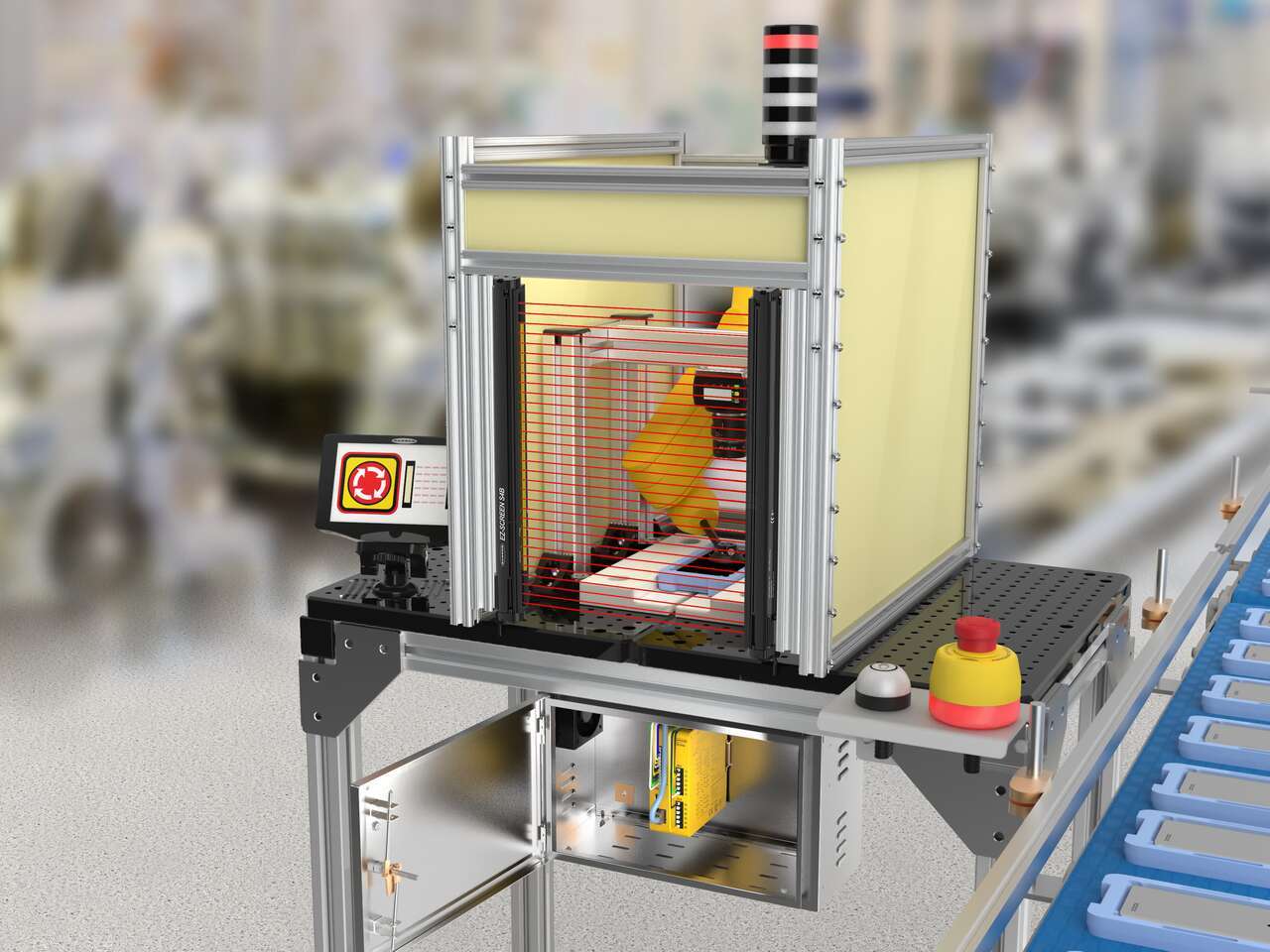

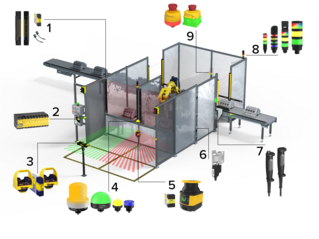

在许多操作点的应用中,操作员必须在离危险非常近的地方工作。 在这些应用中,硬防护装置可能是不切实际的,因为它们会降低操作员的人体工程学和生产力。 安全光幕等光学传感技术在保护操作点的同时,还能促进操作员与机器的无缝互动。

安全光幕通常由发射器和接收器组成,发射器将光束发送到接收器 ,从而形成防止机器危险的感应屏。光幕可以检测出屏幕中阻断光束的个人或物体,并且可以触发停止危险运动。

安全光幕有 2 级和 4 级,取决于它们所保护的风险水平,它们有各种分辨率(光束之间的距离),以检测手臂、手掌或手指。所需的具体分辨率将取决于您的应用,光幕放置在离危险多远的地方,以及根据最小安全距离的计算,多快可以停止危险运动。

请注意:此页面上的信息仅用于培训目的,截至发布时准确无误。在实施任何机器安全措施之前,一定要向安全专家咨询你的具体应用。

端到端检测确保无间隙保护

在操作点应用中使用安全光幕时,要确保手指或手掌可能绕过保护光束的位置不存在检测不到的间隙,这一点至关重要。

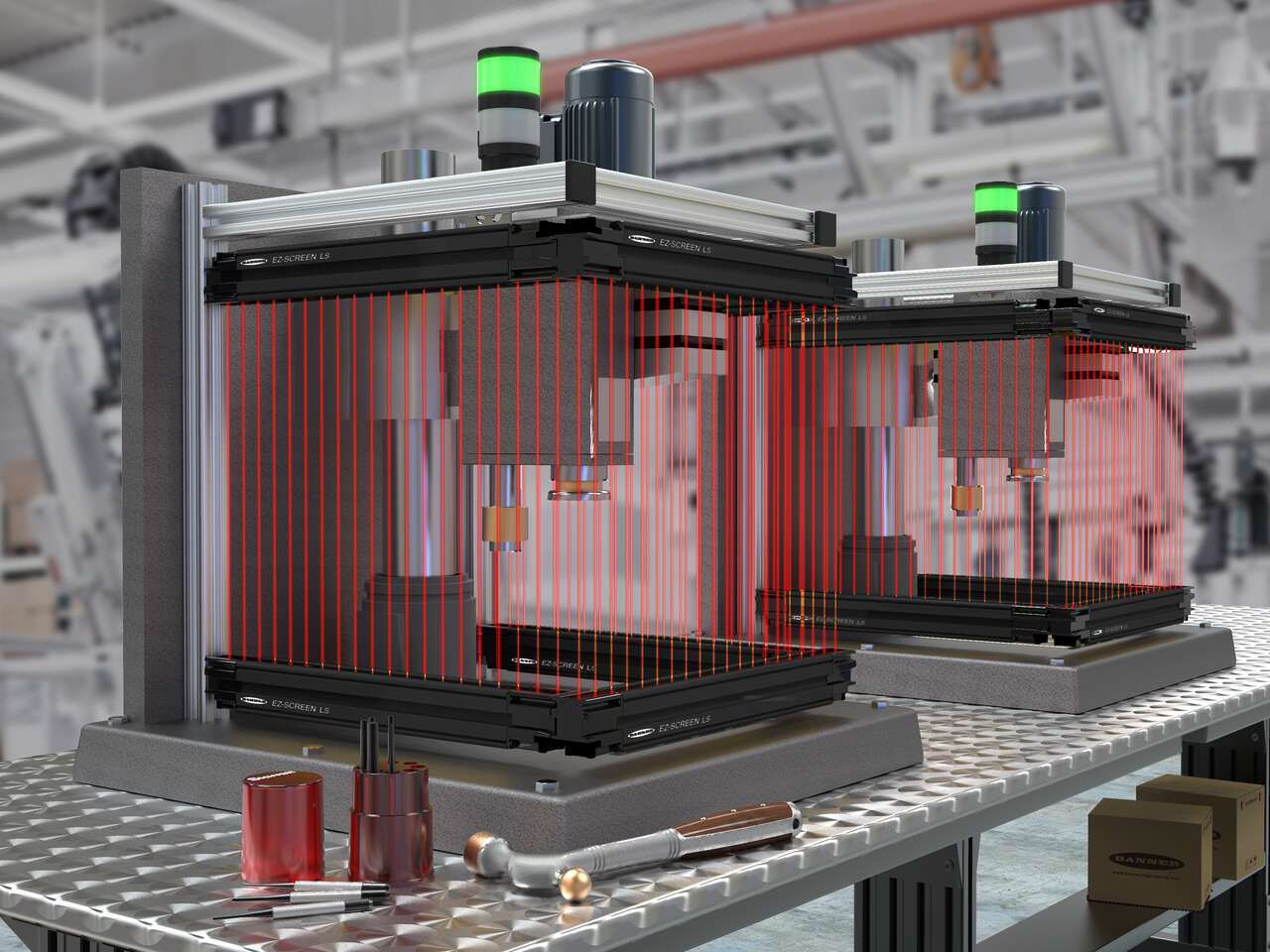

现在,许多安全光幕都具有端对端感应功能,这意味着保护性的光束会延伸到光幕的整个长度。 在左图中,可以看到光束一直延伸到光幕末端,这意味着即使在各种布局中将光幕级联在一起也不会出现间隙。

如果有盲区或其他空隙,在设计安全系统时必须考虑到这些。 在任何安全项目中,重要的第一步都是进行风险评估,以确保实施之前考虑并解决这些因素。

即使在最狭促的空间,也能提供符合人体工程学的安全性

与门和其他硬防护装置相比,光学安全装置通常可以节省空间,并改善操作员的工效。 安全光幕有利于操作员与机器进行更无缝的互动,这有助于提高生产率。

在操作点附近,空间往往是有限的。 而安全光幕可提供各种保护高度,即使在最狭促的空间里,它们也可以保持极其紧凑。

设计坚固,确保一切环境下的安全性

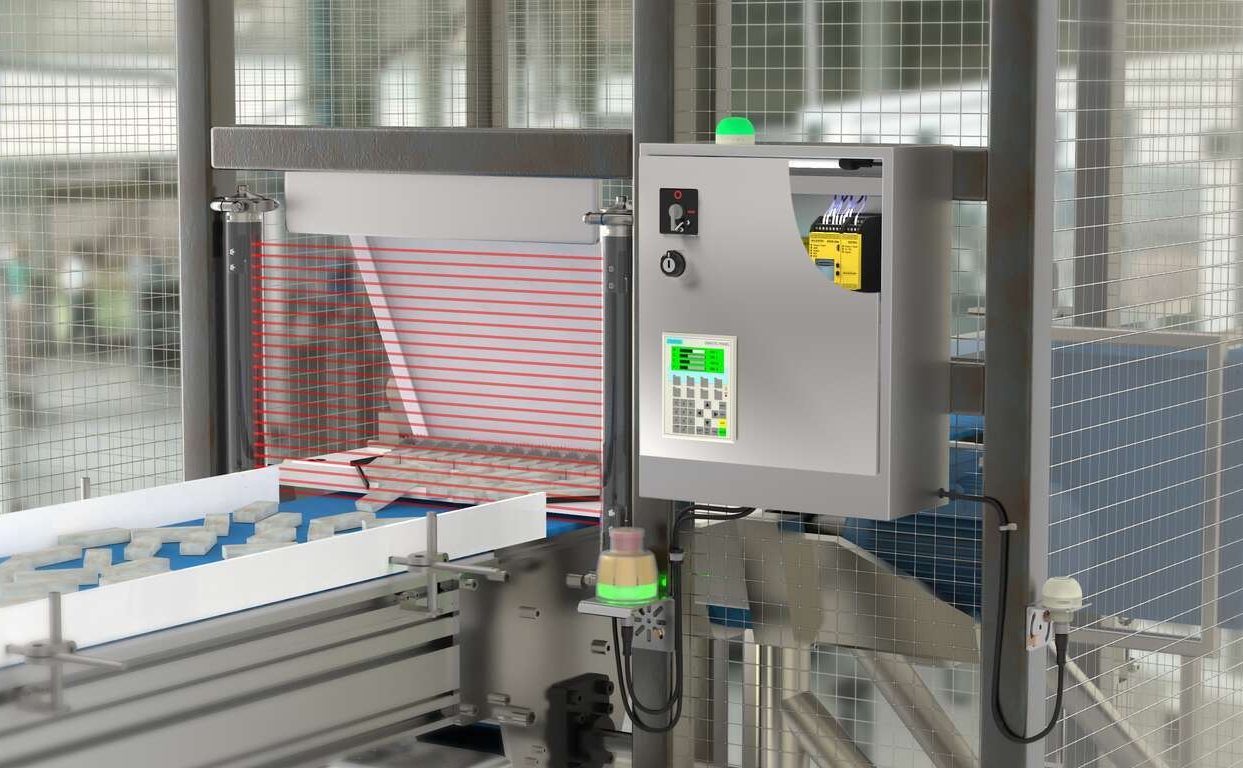

工业环境对安全设备可能是一种惩罚。 在选择工业安全设备时,要考虑周围的环境,确保设备的坚固性符合你的应用要求。例如,重载型铝制外壳和凹陷的透镜等特点可以保护安全光幕不受撞击的损害。

另外,在食品加工应用中,为符合食品安全标准,安装在工艺装置旁边的光幕必须经受频繁的高压高温冲洗。 许多光幕可以配备IP69K等级的保护罩 ,以确保在这些恶劣的条件下可靠地运行。

适用于简单应用的紧凑型光幕

SLC4 safety light curtains are our shortest, most compact safety light curtains for safeguarding points of access and operation on smaller production machines and similar equipment.

- Defined area heights from 160 mm to 320 mm

- 0.1 m to 2 m (4 in to 6.5 ft) sensing range

- 14 mm (finger detection) or 24 mm (hand detection) resolution models available

- Sturdy interior aluminum housing with IP65 polycarbonate enclosure

- Basic functionality with auto start/restart (trip output)

- End-to-end sensing design (no blind zone)