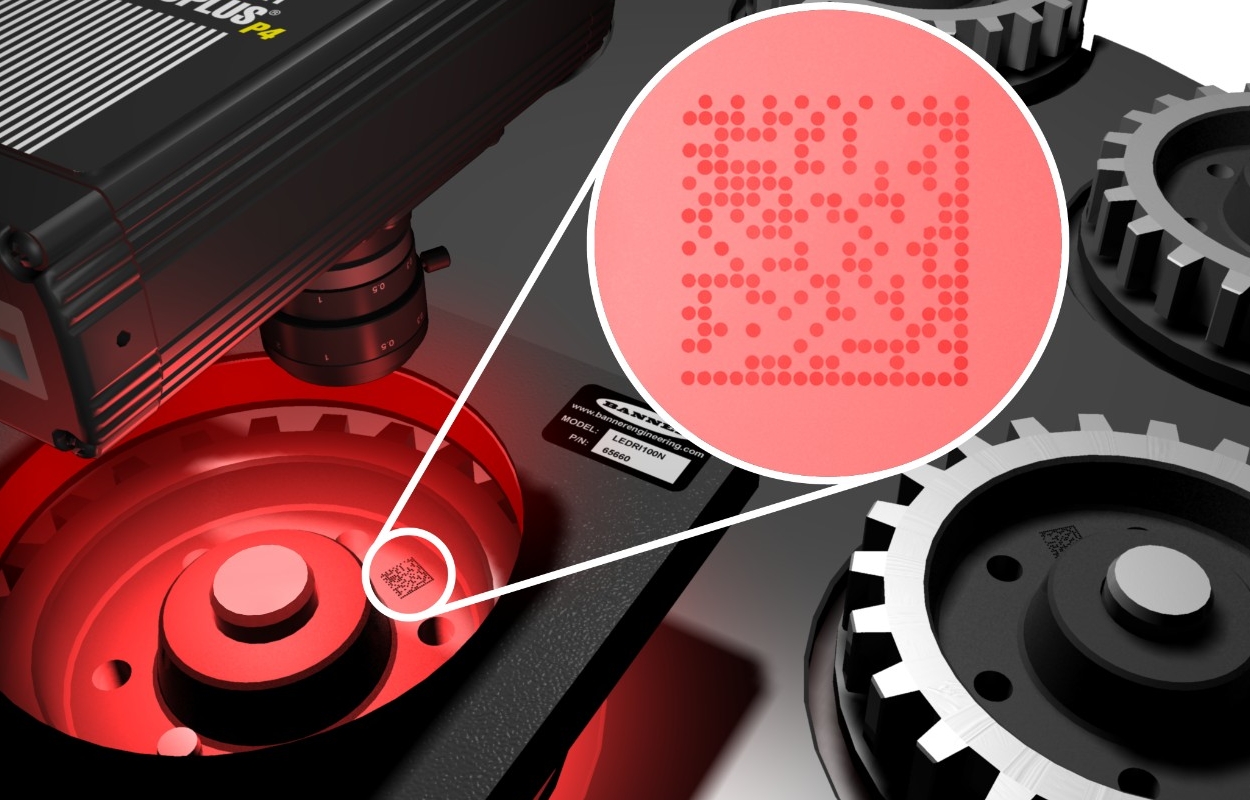

直接部件标记(DPM)读码

极具挑战性的代码

直接零件标记(DPM)是直接蚀刻或印制在零件表面的条码、标记和文字,它们不是用标签贴上去的。 DPM 代码(最常见的是 Data Matrix 代码或 QR 代码)在各行各业中用来跟踪和追溯,尤其是在汽车和电子制造业。

DPM 代码的优势在于它们有永久性,不易被移除、遮盖或损坏。 对于表面有纹理的部件(无法粘贴标签)和非常小的部件(无法贴入标签),也常常适合使用 DPM 代码。 由于 DPM 代码与部件本身的寿命一样长,因此可以在整个生命周期内轻松识别部件,这也叫做“从始至终”的可追溯性。

但由于对比度欠佳,DPM 读码难度极大,因此,找到一种合适的DPM读码解决方案对于可靠识别至关重要。

由于 DPM 代码直接蚀刻在零件上,因此与印在白底上的传统黑色条码相比,其对比度非常低。 此外,DPM 代码、印刷在表面上的位置和方式以及表面本身的特征,都可能存在很大差异,严重影响代码的可读性。

例如,许多 DPM 代码都蚀刻在反光、弯曲或凹凸不平的表面上,读码器很难可靠识别这些表面。

而且表面很少是均匀的,这表明可能含有颗粒、条纹、条痕或其他不规则之处和瑕疵,进一步影响可靠读码。

基于成像仪的先进读码器运用特殊的 DPM 读码算法,能够可靠地解决这些应用问题。 此外,还可以使用低角度照明或不同颜色的 LED 来形成额外的对比度,提高代码的可视性。

基于成像仪的多色 LED 读码器

- 在汽车制造领域,为确保在整个生命周期内追溯汽车零部件,会在每个零部件的表面永久蚀刻 Data Matrix 和其他 2D 代码。

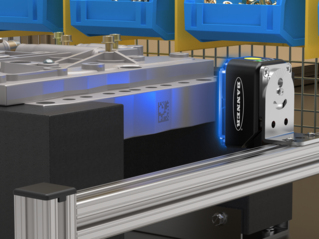

- ABR 7000 等具有暗场照明功能的读码器,非常适合用于读取反光表面上蚀刻的 DPM 代码。暗场照明使用了读码器内置的蓝色 LED 灯,条码看起来会比周围暗得多。

- 条码与零部件表面的对比度增强后,读码器可以捕捉到检测区域的详细图像,Data Matrix 代码的方方面面都清晰可见。

- 然后,代码中包含的信息会得到验证,并通过以太网连接发送到工厂管理系统,由该系统记录数据来进行追溯。

在密闭空间中可靠读码

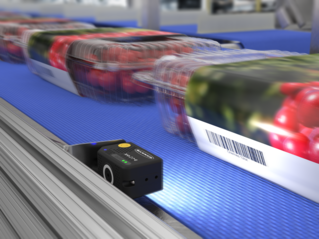

- DPM 代码也是电子制造业的标准代码。

- 这些代码特别富有挑战性,因为除了对比度低之外,代码还非常小,它们是直接刻印在电子元件上的。

- 此外,安装读码装置的空间往往也很有限。

- ABR 3000 等紧凑型读码器非常适合用于电子工业司空见惯的狭小空间。

- 基于成像仪的读码器采用独特的算法,能够可靠识别对比度低的小型 DPM 代码,并通过以太网将数据发送到 PLC 控制装置,实现追溯能力。

基于成像仪的邦纳读码器

除了 DPM 代码,还需要读取其他高难度的代码吗? 基于成像仪的读码器能够可靠地读取任意方向的一维和二维条码。

邦纳提供的读码解决方案能够可靠地解码难以读取、质量低下和损坏的代码,也能可靠读取打印在高反射表面上的代码。

观看视频以了解更多关于新产品的信息,或浏览我们基于成像仪的读码产品的选择。

基于成像仪的读码器

ABR 7000 条码读取器的解码能力出色,提供多种分辨率和多种镜头选择。

- abr 7000 条码读取器提供高级功能,包括延伸读取距离和视野、高级照明、各种焦距(包括自动对焦),并且能够将多个读取器串联起来。

- 强大的解码功能,难以处理的一维和二维码(包括 DPM 和低对比度代码)也能读取

- 使用板载按钮或安装了邦纳免费操作软件 - Barcode Manager 的电脑快速配置

- 在一个套件中提供集成式 LED 照明和简单的焦点调整,充分发挥灵活性

- 多种镜头选项,可用于简化设置和配置,包括由软件调整的自动对焦,轻松适应读取距离的变化。

- 工厂通信选项包括以太网通信和串行通信,可在制造车间进行集成。

- 嵌入式 Web 服务器接口,用于监控网络上的图像和统计信息

对比基于成像仪的读码器

abr 3000 条码读取器外形紧凑,解码能力一流,并且提供多种分辨率和多种镜头选项。

- 强大的解码能力,难以读取的一维和二维码也能读取

- abr 3000 是狭小空间和近距离读码的理想选择

- 紧凑的金属外壳,适用于工业环境

- 使用板载按钮或安装了邦纳免费操作软件 - Barcode Manager 的电脑快速配置

- 在一个套件中提供集成式LED照明和简单的焦点调整,充分发挥灵活性

- 提供以太网或usb通信选项,可集成到生产车间

- 嵌入式服务器接口,用于监控网络上的图像和统计信息

iVu BCR 系列

基于成像仪的读码器

iVu BCR 系列条码读取器将强大的解码能力和使用便捷的特点融于一体,能解决高难度的追溯性应用。这些多功能条码读取器提供各种各样的镜头、照明和用户界面选项。

- 读取广泛的一维和二维条码,包括损坏、变形和其他难以读取的条码

- 能够在一次检测中读取任何方向的多个条码

- 使用集成的触摸屏、远程触摸屏或 PC 界面来设置、管理和监控检测

- 以太网和串行通信协议简化设备集成,实现工业物联网数据采集

- 坚固的 IP67 级外壳,是狭小空间和工业环境的理想选择

- 众多的集成照明选项简化了安装,优化了对比度

- 可更换镜头,包括各种标准选件和 C 型支架选件,能满足任何应用的需求