装配和排序

快速而准确地构建套件和装配体

配料涉及将独立但相关的物品组装成一个单元或套件,并一起包装。

在及时生产(JIT)中,排序是指在需要时准确地将成套的材料送到下一个工位,以确保最大的效率。

例如,在汽车制造业中,成套的零件在需要成套的时候正好被送到下一个生产阶段。 以这种方式组装成套设备也被称为 "离线成套设备。"

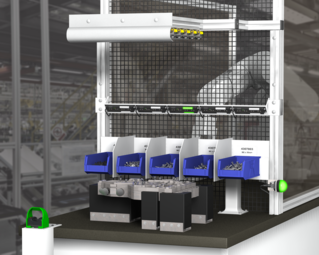

拣选解决方案有助于确保成套设备以快速的速度准确组装,并能在正确的时间交付给下一个生产阶段。

步骤多、套件杂、容错率低

确保配料的质量至关重要

配料和排序应用可能具有挑战性,因为套件和其他组件通常由许多不同的部件组成。 每个套件都必须正确组装,才能确保最终用户或下一生产阶段的组装人员收到完整的套件。

由于物品数量众多,而且在一个工位组装的套件种类繁多,组装人员很容易记不清套件中已经放了哪些物品。 例如,他们可能会不小心遗漏物品或重复放入物品,从而增加成本,难以管理零部件库存。

手动验证每个套件是否完整,是否有重复件,既费时又容易出错。 因此,我们需要一种能够简化装配任务并验证准确性的解决方案。

及时排序应用离不开快速准确的配料,确保套件在正确的时间到达下一个工位,并包含所有必要的部件。

验证拣选的组件是否正确

实时检查拣选准确度

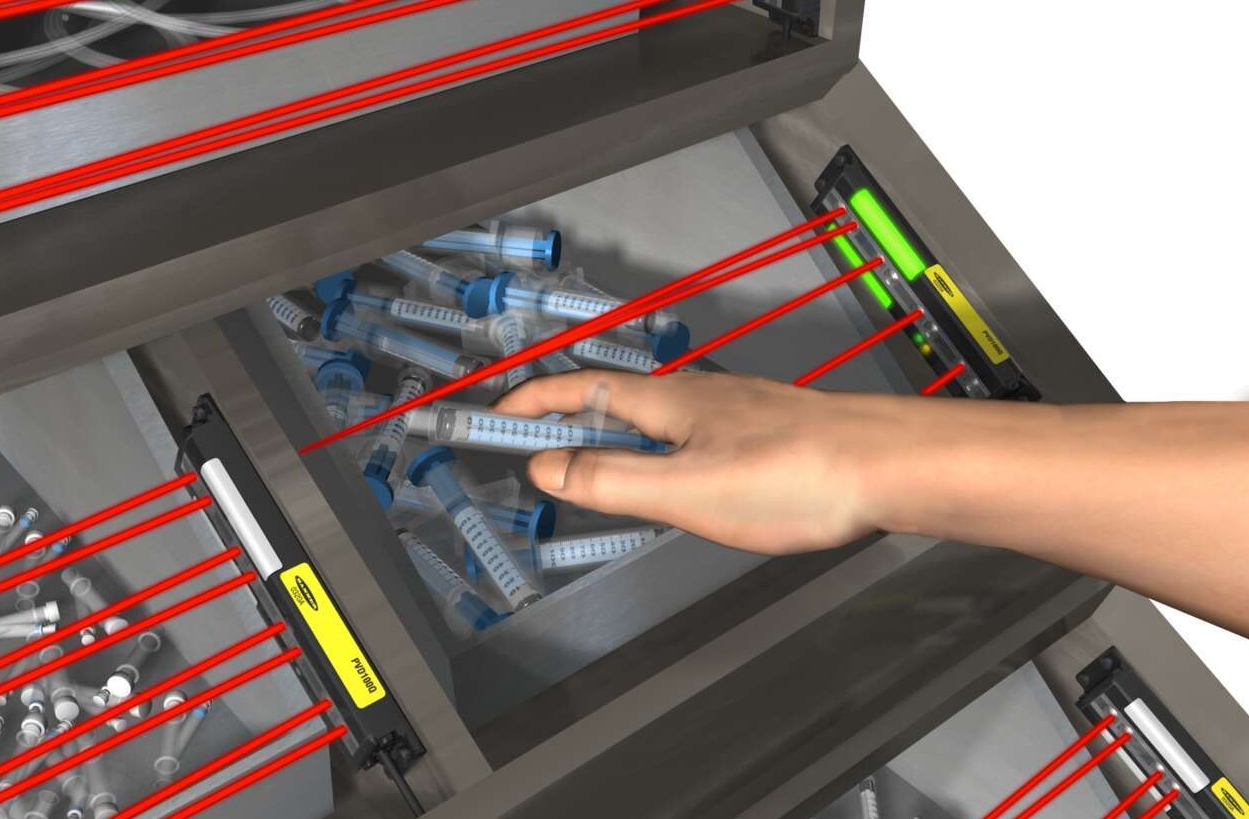

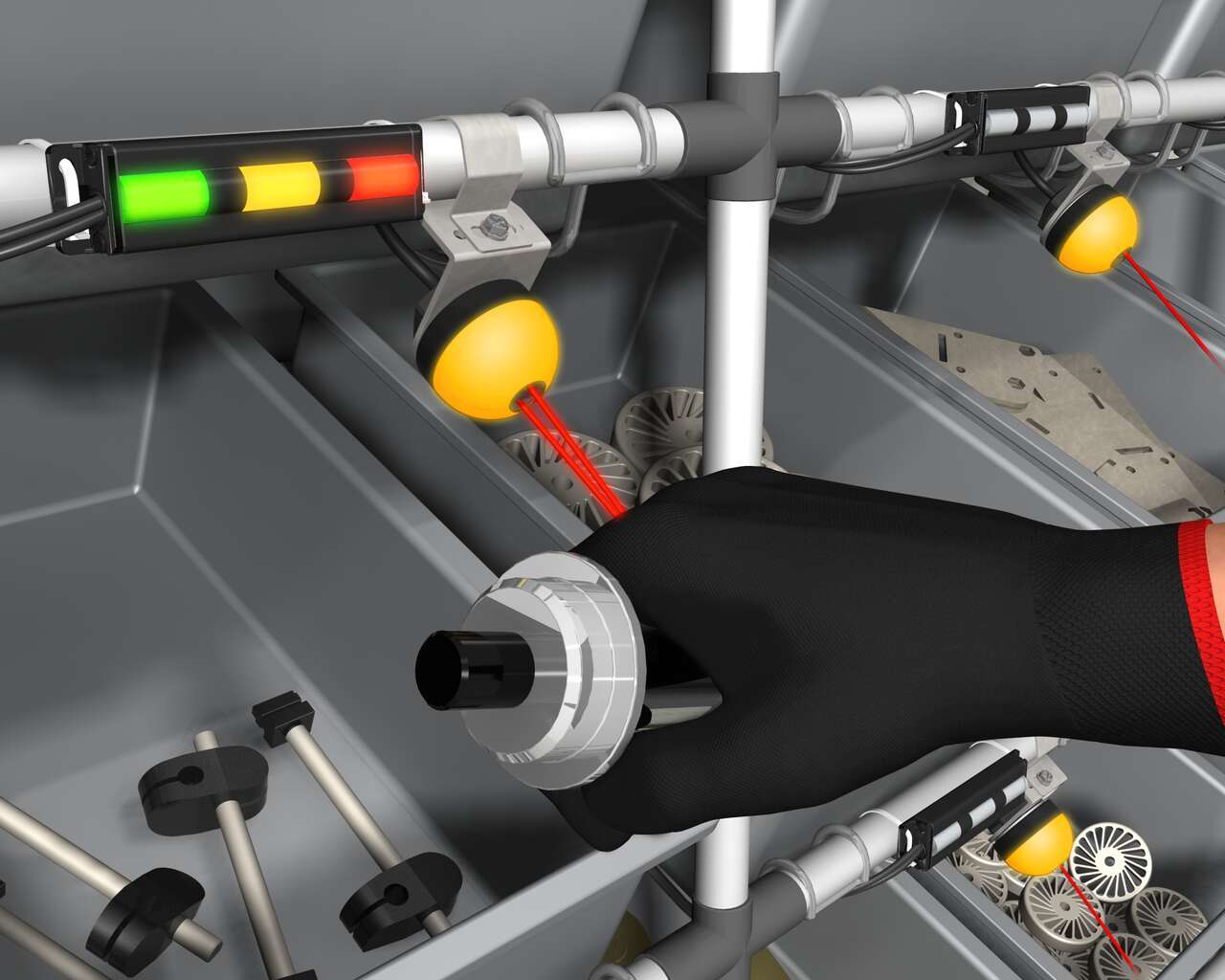

- 具备光学感应功能的拾取指示灯装置,可以实时检查拣选准确度。

- 当一只手伸进料盒并中断检测光束或阵列时,这些装置就会进行检测。

- 正确执行拣选后,黄色 LED 灯会确认操作员从正确的料盒中进行了拣选。

- 如果操作员将手伸入错误的料盒(例如拣选错误的物品或不按顺序拣选),指示灯就会变红,表示出错。

提高整体效率

减少时间浪费,节约成本

- 光导解决方案加快了新员工的上手速度,也加快了新品组装的培训时间。 只需稍加培训,就能轻松快速地解读不同颜色的指示灯。

- 拾取指示灯解决方案减少了重新读取说明以及检查和重新检查工作所浪费的时间。

- 通过在每个步骤对零件进行验证,拾取指示灯解决方案可以减少装配过程中的错误,节省下游质量检查的时间。

- 提高装配和检验阶段的效率可降低管理成本,提高盈利能力。

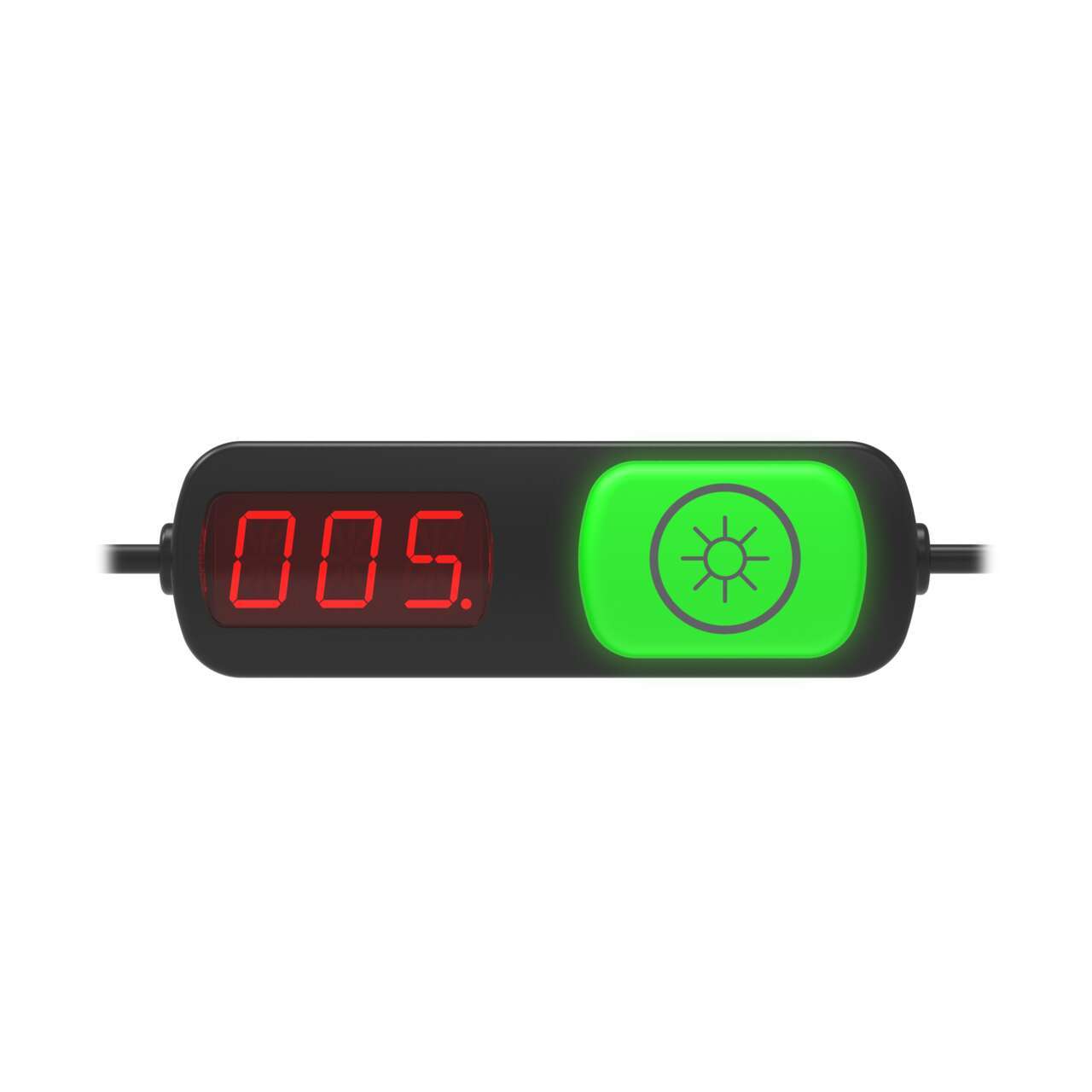

K50 Pro 系列

拾取指示灯装置

K50 Pro触摸式系列是一个多功能产品系列,将大而明亮的指示灯与固态切换功能相结合,只需触摸即可激活。适合精益生产和零部件拾取操作。K50 Pro 触摸按钮将成熟的触控技术、坚固的特点与 RGB LED 的多功能性融为一体。K50 Pro触摸按钮与Pro Editor软件兼容,可轻松自定义。

- 明亮的 LED 指示灯与经由触摸激活的开关功能融于一体

- 使用邦纳的 Pro Editor 软件和 Pro Converter Cable 可对各兼容型号编程,从而定制各种颜色和直观显示效果

- 坚固的 IP67 和 IP69K 级结构,适用于高压冲洗环境

- 采用人机工程学设计,操作时无需施力,减轻对手和手腕的应力

- 从食品和饮料到汽车行业,非常适合用于各种行业和环境中的拾取指示灯和呼叫按钮应用

- 一个设备中最多可以使用十四种颜色(绿色、红色、黄色、蓝色、白色、青色、洋红色、橙色、琥珀色、柠檬绿色、春绿色、天蓝色、紫罗兰色和玫瑰色)

- IO-Link 型号拥有由主设备动态管理的 Pro 完整版功能,并为全面定制状态提供单独的 LED 控制

K30 系列

拾取指示灯装置

小型K50系列、K30系列拾取指示灯按钮将明亮的指示灯与固态触摸式切换功能相结合。

- 采用人机工程学设计,操作时无需施加任何物理压力,可以防止手和手腕受到压力

- 用手指触摸简化操作

- 可以不戴工作手套轻松启动,也可以戴上工作手套启动

- 坚固耐用的全封闭IP69K结构,适用于高压冲洗环境

- 适用于各行各业的拾取指示灯和呼叫按钮应用

- 单色和双色型号可用于解决各种各样的应用