工厂通信与流程优化

增强通信,提高工人生产力

工业物联网 (IIoT) 技术不只是对优化机器有用。事实上,无线技术也可以实现人类工作者之间的无缝互动,并且能对手动或半自动化生产装配线的效率产生重大影响。

继续阅读本文,了解工业物联网技术如何在整个工厂中促进通信和简化人机流程。

运用数据识别流程改进

无线呼叫零部件、服务或托盘拾取系统可以提高效率,允许多达 18 个工作站呼叫六部叉车或 Hi-Lo。 无线解决方案有助于叉车司机和/或主管更快做出响应,表明已受理请求。使用无线指示器创建呼叫系统时,工作站可以保持稳定的工作流程,快速解决关键问题。

无线解决方案还可以跟踪履行请求的总时间、请求数量和确认请求的时间。这样一来,管理人员就可以分析每个工作站的平均运送时间和确认时间,并根据需要改进流程。

减少不必要的签到时间

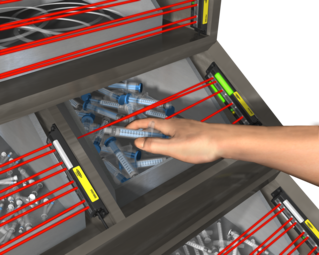

机器操作员不必走向管理人员区域来寻求技术问题协助,而是可以利用无线系统,此类系统上有相连的按钮或开关和塔灯,在生产线需要协助时,可以利用它们来向管理人员发出警报。

例如,可以适当设置通知系统,这样操作员便可按下按钮或拨动开关来通知管理人员或技术人员,需要由其协助处理生产线上的问题。如果无线按钮配备有 LED 状态指示灯,那么还可以对 LED 进行适当配置,通过改变颜色告知管理人员或技术人员在赶来途中,从而促进双向通信。

使用无线通知系统减少了技术人员和管理人员经常检查每条生产线的需要,也减少了工人离开工作站寻求协助的需要。通过简化通信,管理人员、技术人员和生产线工人能更有效地利用自己的时间。

无线按钮与照明挂件

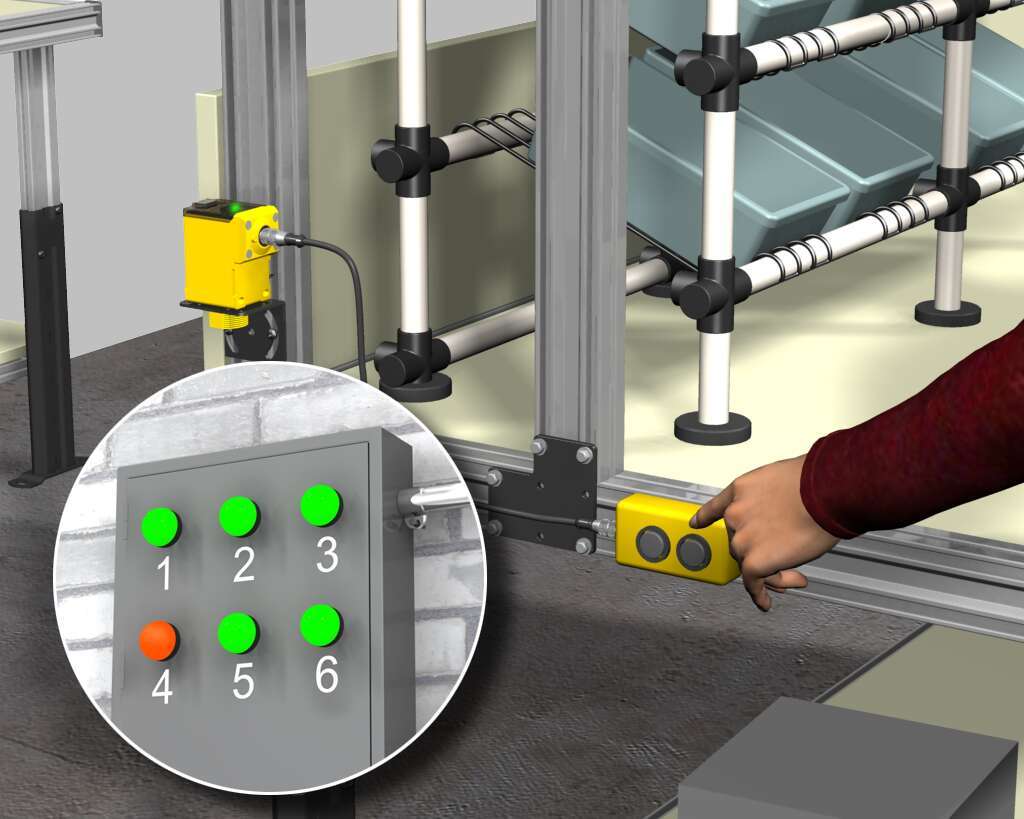

Sure Cross® 无线 Q120 按钮和照明挂件是一款自主型无线节点,它能实现操作人员和多达六个远程和/或移动设备之间的双向通信。

- 6 个独立控制的按钮输入,允许操作人员无线发送状态更新、确认、启动流程和驱动设备。

- 6 个红色和绿色 LED 指示灯,在本地指示来自远程或移动设备和器材的状态。

- 可配置 DIP 开关

无线 LED 触摸按钮

K70 70 mm 无线触摸按钮是一种容易激活的大型固态开关,提供高度醒目的指示器。该系列的触摸按钮适用于拾取指示灯、呼叫按钮和一般工业应用。

- 完美抵制水喷雾、清洁剂、油和其他外来物质导致的误触发

- 符合人体工程学设计,可消除反复操作开关对手、手腕和手臂产生的压力;操作时无需施力

- 可以不戴工作手套启动,也可以戴上手套启动

- 提供九种颜色选项以及单色、双色和三色型号

- 12 至 30 V 直流操作