自动质量控制

及早发现问题,节省成本

如果零部件和组件中存在缺陷和失误,就会对下游流程、生产效率和产品质量造成负面影响。

可靠一致的零部件和组件检查能帮助制造商在制造流程中及早发现潜在问题,最大限度减少成本高昂的产品浪费,缩短生产时间。

邦纳在众多检测技术领域拥有丰富的专业知识,为检测缺陷、测量组件、监控公差和验证属性提供了最佳质量控制解决方案。

需要坚固、可靠的传感器

自动质量控制应用往往涉及检测充满挑战性的目标,例如透明和反射的目标、深色背景下极暗的目标、有多种颜色过渡的多色目标以及高速移动的目标。

再小的失误也可能恶化成严重故障,进而蔓延至整条生产线,因此有必要进行精密检测。在某些应用中,质量控制检测可能在极端恶劣的环境下进行,在这样的环境里,检测技术可能会暴露于尘垢、高压冲洗、机器振动等等。

邦纳提供了一系列坚固而又可靠的光电、激光测量和视觉传感器,即便在最严峻的应用中,这些传感器依然能改善您的自动质量控制流程。 继续阅读以了解更多信息,或与我们联系以讨论您的具体应用。

可靠检测每个目标

快速可靠地检测每个目标,对于确保一致的吞吐量同时又不影响质量至关重要。

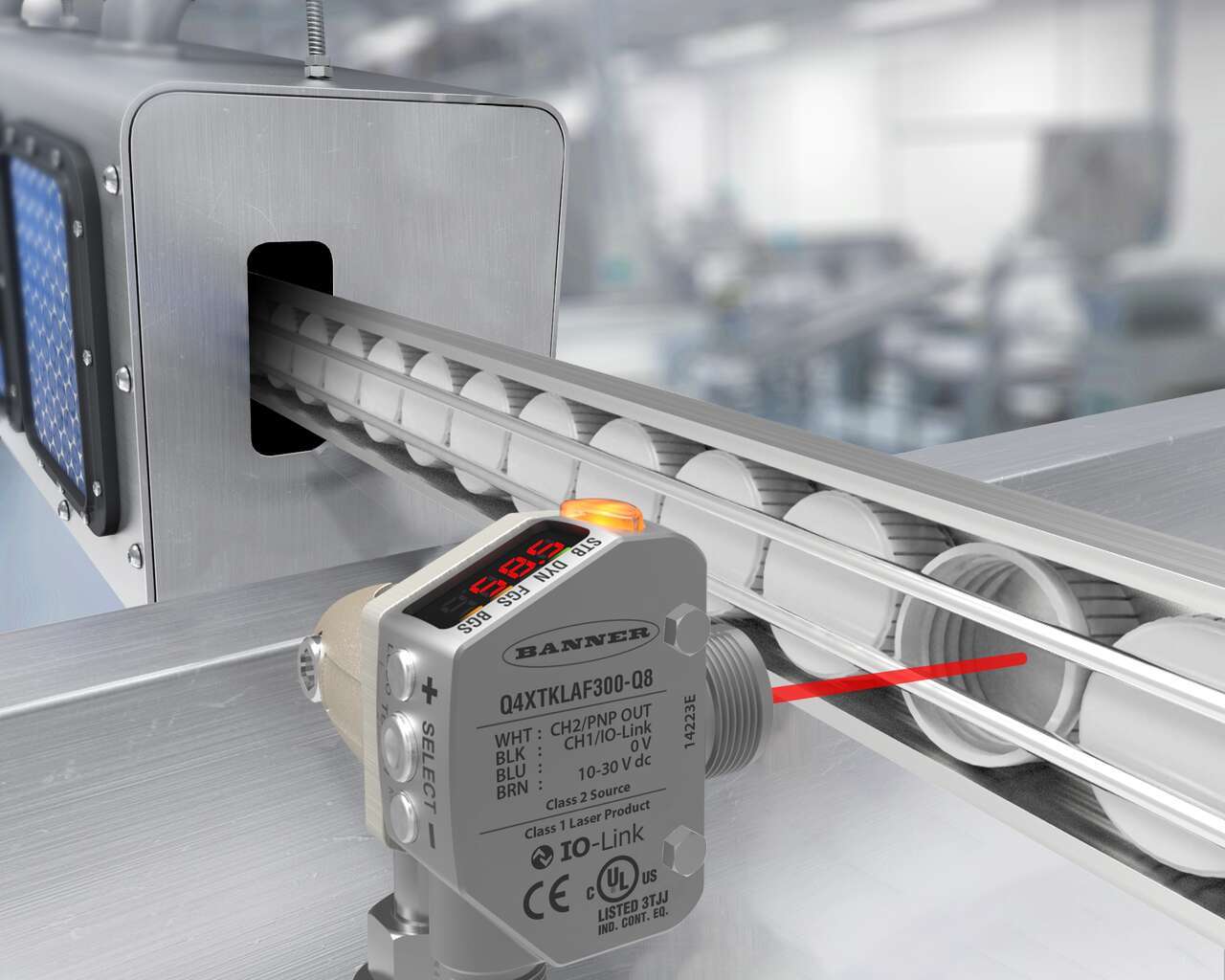

得益于激光测量技术的进步,过去充满挑战性的检测目标(包括透明、反射和低对比度目标),在如今的传感器面前化为乌有。 例如,Q4X 激光测量传感器能可靠检测同样深色背景下极其深色的目标。

此外,由于推出了可同时测量距离和光线强度的双模式,邦纳智能激光测量传感器可以使用单独一台设备可靠检测基于距离和基于对比度的条件,从而节省库存成本。

另外,借助 IO-Link 通信,用户可以跟踪传感器性能,识别检测结果中的趋势,甚至可以预测何时需要维护,这样就可以在发生传感器故障之前解决镜头变脏等简单问题。

保持严密的公差

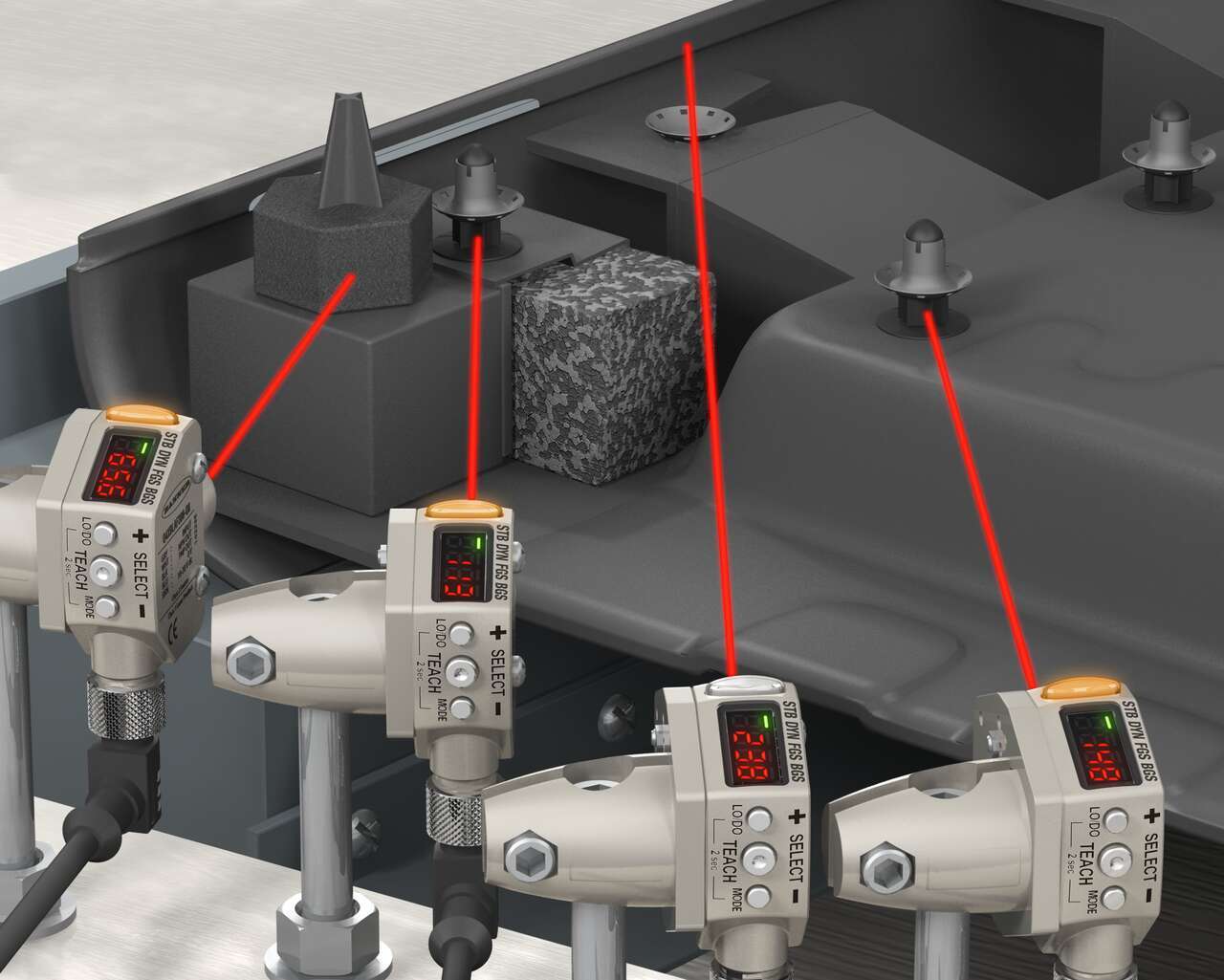

在需要解决的最具挑战性的应用中,其中一些便是需要精密测量的质量控制应用。鉴于公差要求极其严格,因此需要使用可靠的解决方案来测量微米级零部件,以检测零部件尺寸、厚度、方向、放置等方面的细微差别。确保零件符合严格的质量标准有助于减少下游问题,并降低由于零件缺陷而召回产品的风险。

激光测量传感器是用于精密检测零部件的常见解决方案。不过,即使在理想实验室条件下表现出色的激光传感器,在实际环境(包括目标颜色和反射率的变化、环境温度的波动以及安装不当引起的振动)进行精密测量可能很有难度。

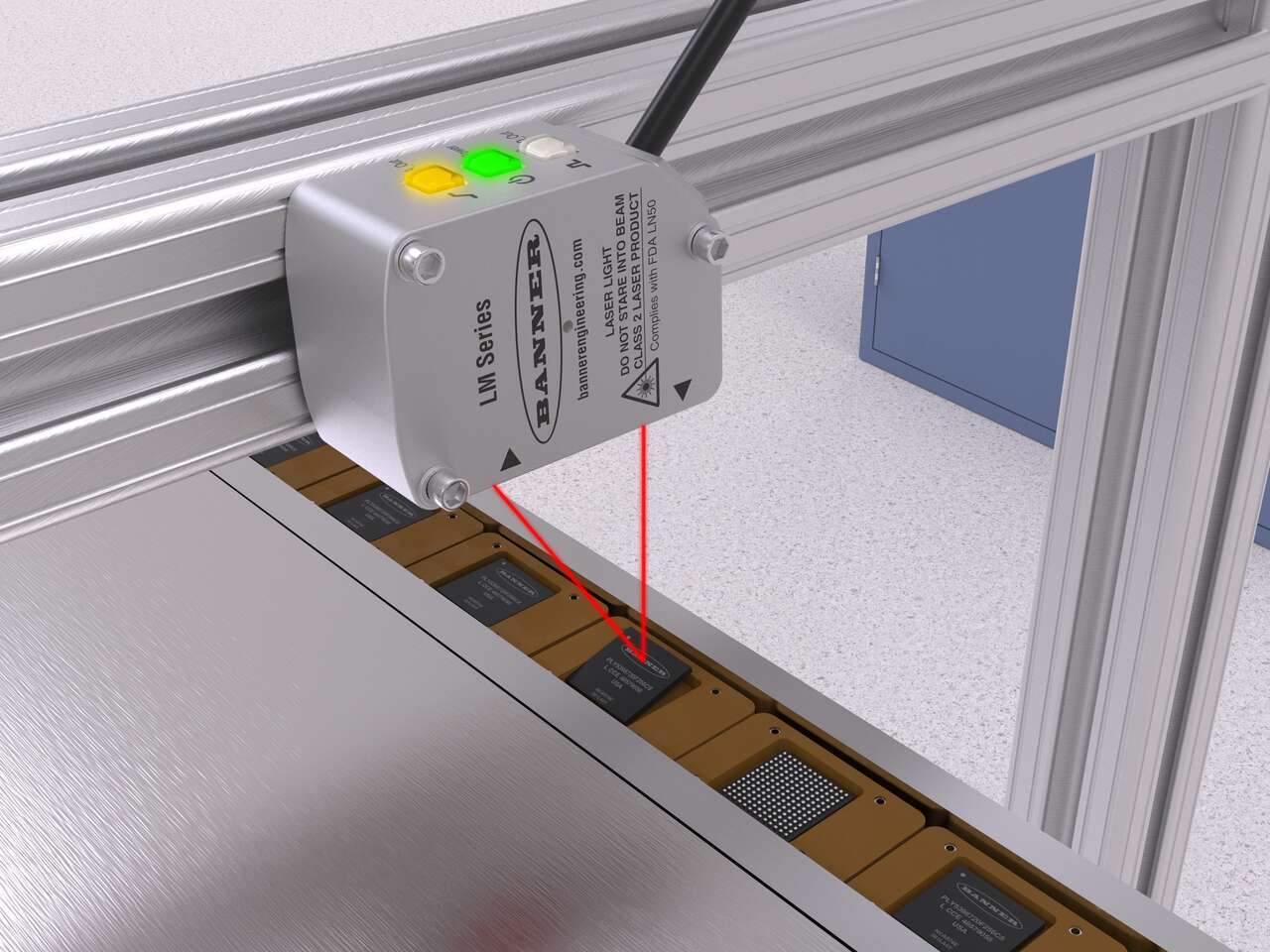

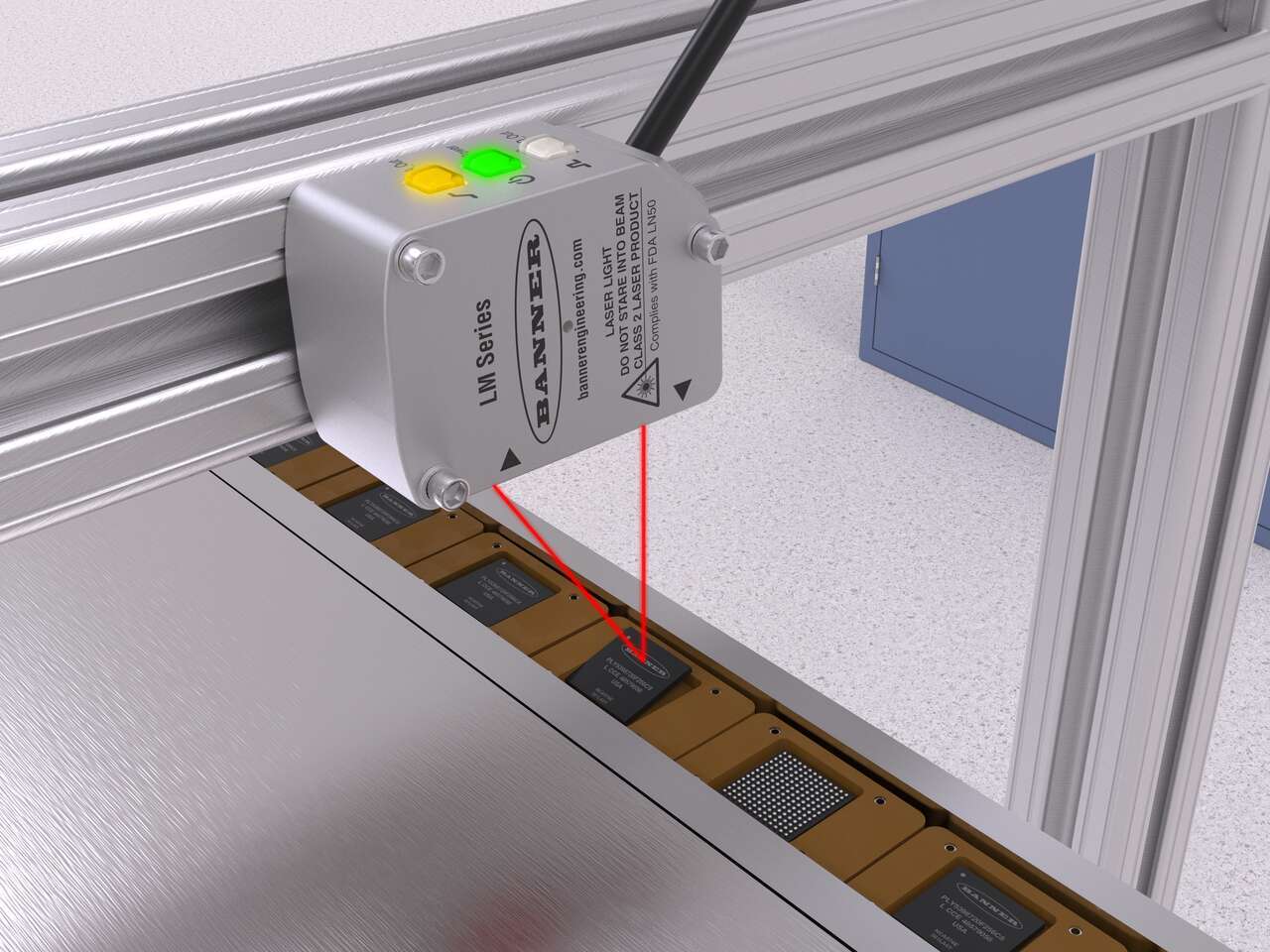

来自邦纳的 LM 系列精密测量传感器具备一流的性能,能高度稳定、可靠、精密地测量各种实际目标。

从源头防错

防错是指在源头而不是在生产线上防错,避免流程中出现缺陷。 从源头防错可以防止问题在下游加剧,因此能显著提高生产力。

在自动化流程中,可以使用传感器和视觉系统等防错解决方案,确保在流程继续前解决问题。

同时,在零部件拾取等手动流程中,视觉警告会使用彩色和/或直观显示效果的指示灯清晰地向操作员指示其操作正确与否。光导组件便是使用视觉指示进行防错的好例子。

精密测量传感器

LM 系列精密测量传感器为用户带来了直观体验,设备尺寸紧凑,提供一流的性能和稳定性。

- 分辨率为0.002-0.004 mm的精确测量

- 快速0.5 ms响应速度和0.25 ms采样率

- 紧凑的外壳设计适合狭小空间

- 一流的热稳定性和机械稳定性

- IP67和316级不锈钢,具有化学兼容性

- 可选远程传感器控制器显示(RSD),用于远程监视和设置

- 在一个型号中支持离散量和模拟量输出,并通过IO-Link®支持工业4.0 / IIoT

iVu 系列

视觉传感器

iVu 和 iVu 彩色图像传感器用于监测零部件的类型、尺寸、方向、形状、位置、颜色或颜色变化。

- 一体化解决方案,包括相机、控制器、镜头和指示灯

- 使用 Vision Manager PC 软件、板载触摸屏显示器或远程触摸屏在短短几分钟内即可配置完毕

- 使用各种灰度或颜色工具进行多点检验

- 紧凑、坚固的外壳,防护等级达 IP67,配备各种颜色的集成环形灯,其中包括红色、蓝色、绿色、白色、红外和紫外灯

- 可互换镜头,包括 C 卡口,最大程度实现应用灵活性

- 以太网/IP™、Modbus/TCP、PROFINET®、PCCC 和串行 RS-232