DXM1200 IIoT Gateway 系列

邦纳 DXM1200 IIoT Gateway 无线控制器几乎可以收集任何地方的状态监测数据并加以处理,然后发送到世界上的任何地方。

A car wash depends on multiple systems working in tandem. Failure in any piece of equipment could cause an unexpected shutdown, resulting in lost revenue and unplanned maintenance.

But Banner Engineering can help you detect equipment breakdowns before they happen.

Maximize vehicle throughput and reduce unexpected downtime with Banner Engineering’s Predictive Maintenance Solutions for Car Washes.

To monitor equipment in the back room, use Banner’s Q45 All-In-One Series sensors, starting with an ultrasonic model that accurately measures the water level in the storage tanks. The vibration and temperature of the delivery pump’s motor gets monitored with another peel-and-stick Q45, and an additional Q45 monitors the water pressure on the main water line.

Further down the line, monitor the vibration and temp of all the different distribution pump’s motors, such as at the detergent pump station, sealer stations, and the high-pressure water pump stations.

Additionally, monitor the reclaim storage tanks for low water levels, which may indicate the RO’s filter needs cleaning. The reclaim delivery pump’s motor is also outfitted with a temp and vibration sensor to alert users to mechanical maintenance needs.

But monitoring solutions don’t have to stop at the water system; nearly any equipment can be monitored, such as the pneumatic air system. Temperature and vibration sensors monitor the air compressor motors alongside a current sensor for consistent power usage, as well as a pressure sensor on the primary air line.

Outside, monitor the central vacuum’s motor with a temp and vibration sensor. The filter’s efficiency can be calculated by comparing the air pressure both upstream and downstream of the separator, indicating when the filter needs cleaning.

All the data from each of these sensors is transmitted wirelessly to a DXM controller mounted in a safe and convenient location. Sensor calculations are performed inside the controller, and data can be transmitted to wherever you need it via Ethernet cable or a cellular connection. Additionally, alerts can be sent to workers via email or text message, so mechanical problems can be addressed quickly.

But, passive monitoring doesn’t have to stop there.

Back in the tunnel, use a temperature and vibration sensor to track the machine health and performance of the conveyor’s motor and gear box. Additionally, consider using a Q45 to track vibration on the air blowers.

Next, add a T30RW radar sensor to the tunnel entrance and exit to reliably detect when vehicles arrive and leave.

Further inside the tunnel, accurately detect vehicles at specific locations, such as an applicator arch, with the QS30 Photoelectric Sensor.

And speaking of applicator arches, Banner's extensive line of customizable RGB lights, many of which are programmable and animated, will add an exciting splash of color and movement while also indicating different wash levels, customer-selected sealers, progress indication, and more.

The only limit to indicator integration is your imagination.

To learn more, visit BannerEngineering.com/carwash

邦纳 DXM1200 IIoT Gateway 无线控制器几乎可以收集任何地方的状态监测数据并加以处理,然后发送到世界上的任何地方。

这款通用型可编程指示灯配备 50 毫米圆顶或平面视窗,提供更加醒目、更为明亮的状态指示。也可提供兼容 Pro Editor 软件的型号或配备 IO-Link 通信功能的型号,实现更高程度的多功能性和定制能力。

K70 指示灯是直径为70 mm的大型指示灯,在一个指示灯里可支持多达5种颜色。他们是明亮而坚固的指示灯,可用于多种应用设备。

Q45 系列一体式套件将无线节点、传感器和电池电源组合在一个部署简便的设备中,用于监控远程和难以接近位置处的资产和设备。

QM30VT 系列振动和温度传感器可提供卓越的精度,甚至可以检测机器运行状况和性能的微小变化,从而尽早发现潜在问题。

高能型检测距离达200米,可提供继电器输出型号。

T30R 传感器是超声波传感器的长距离替代产品,它能在极端的户外条件和其他充满挑战性的环境中提供更加可靠的检测和位置反馈。与传统的 24 GHz 雷达传感器相比,它的特点是盲区更短、精度更高,而且能看到范围更广的目标。

可提供又大又亮的预装配塔灯,也可以根据定制要求提供模块化灯段。熄灭时呈灰色,消除错误指示。

邦纳在扩大 WLS27 系列灯带的阵容,纳入了配备 RGBW LED 的可编程型号,用于指示、照明和检测应用。这些新型号可通过邦纳的 Pro Editor 软件或 IO-Link 通信进行编程。

紧凑型28 mm LED 光源,适用于多种工业应用。可提供运动侦测传感器,多种透镜和窗口以获得最大的灵活性。

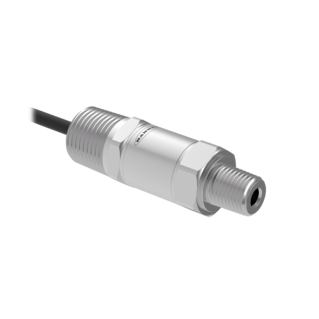

Performance 系列多合一压力传感器和无线节点可轻松监控远程和难以接近位置处的系统和设备的压力水平,无需搭建有线基础设施来连接设备。

Sure Cross® 温湿度传感器可在各种环境中工作,能够提供温湿度测量解决方案。与Sure Cross 无线电台一起使用,这些传感器可以轻松监控环境条件,而无需昂贵的接线到监控点。

Application solutions, new product updates, answers to frequently asked questions, and more delivered 1-2 times a month.