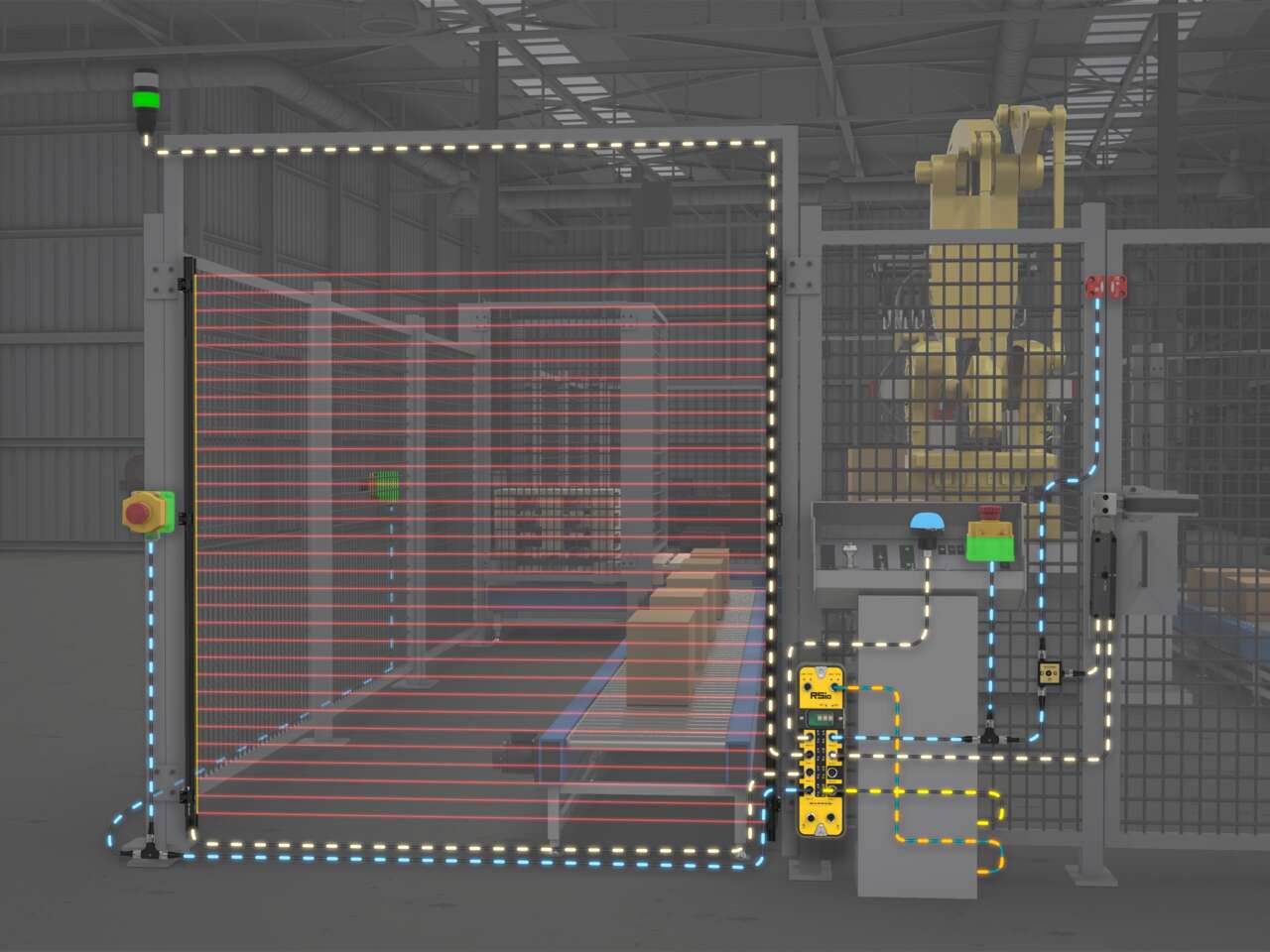

Complete Palletizer Coverage

Use RSio to create a complete safety solution for robotic palletizing cells that takes advantage of hybrid I/O and In-Series Diagnostics (ISD).

通过色彩组合、交互式控制和声音提示,保持每一道工序更加清晰明了,过程信号与状态信息一目了然。

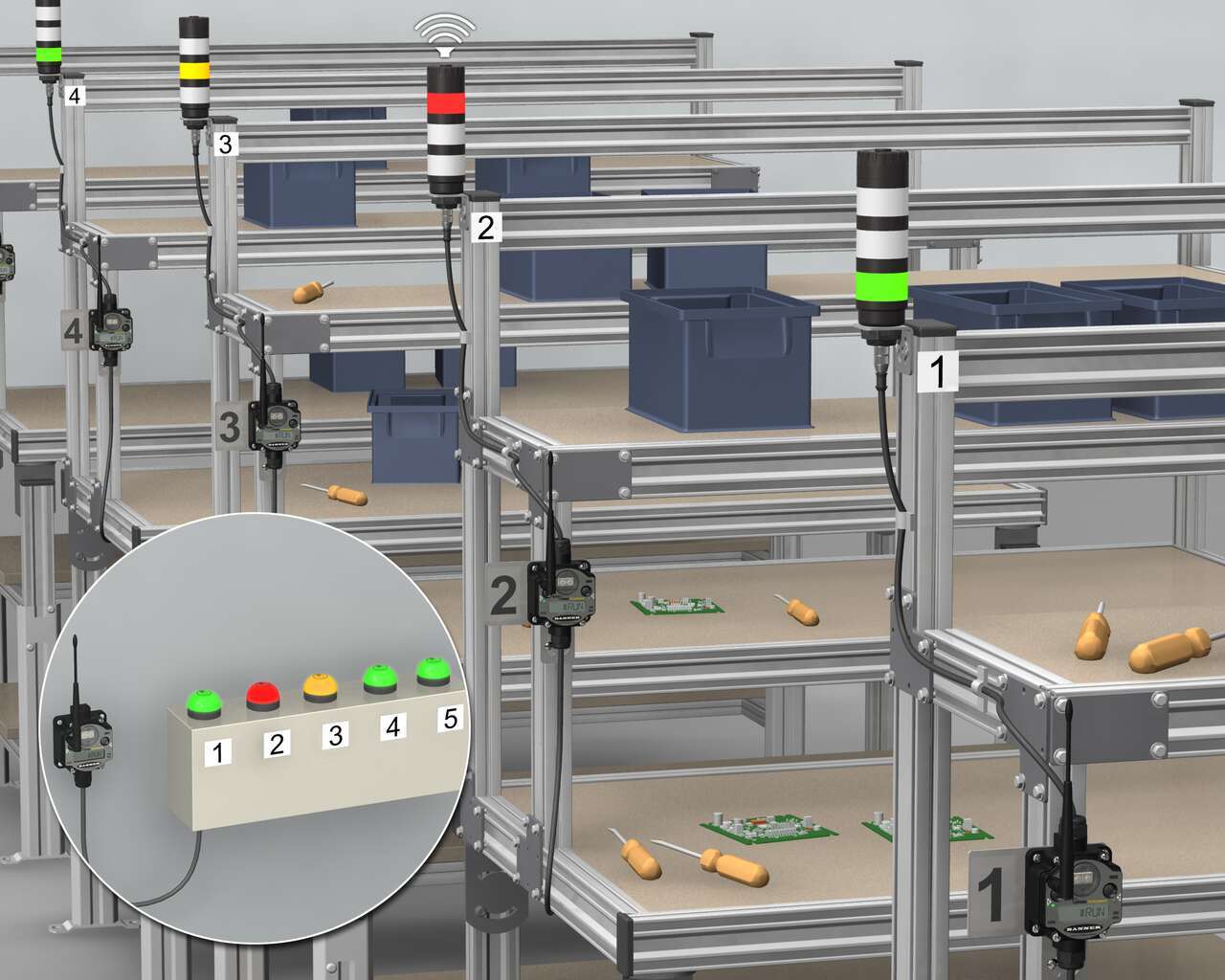

标准型号开箱即可实现可靠的状态指示;可编程型号则进一步扩展功能,支持响应配置,并可通过 IO-Link 或 Modbus 实现实时控制。颜色、LED 直观显示效果等均可借助免费的邦纳 Pro Editor 软件进行设置,也可通过通信协议动态控制。在高密度 Modbus 系统中,搭载邦纳高速串行协议 PICK-IQ 的型号可提供更迅捷的视觉反馈。针对特殊应用场景,还可提供适用于危险区域、卫生环境、户外强光条件以及本地化 I/O 控制的专用型号。

无论采用离散信号还是基于协议的控制方式,过程状态都能转化为直观反馈,引导操作、缩短响应时间,并实时确认进展。当需要提升节拍效率、增强现场感知或进一步优化响应速度时,总有一款 K50 能够满足您的需求。

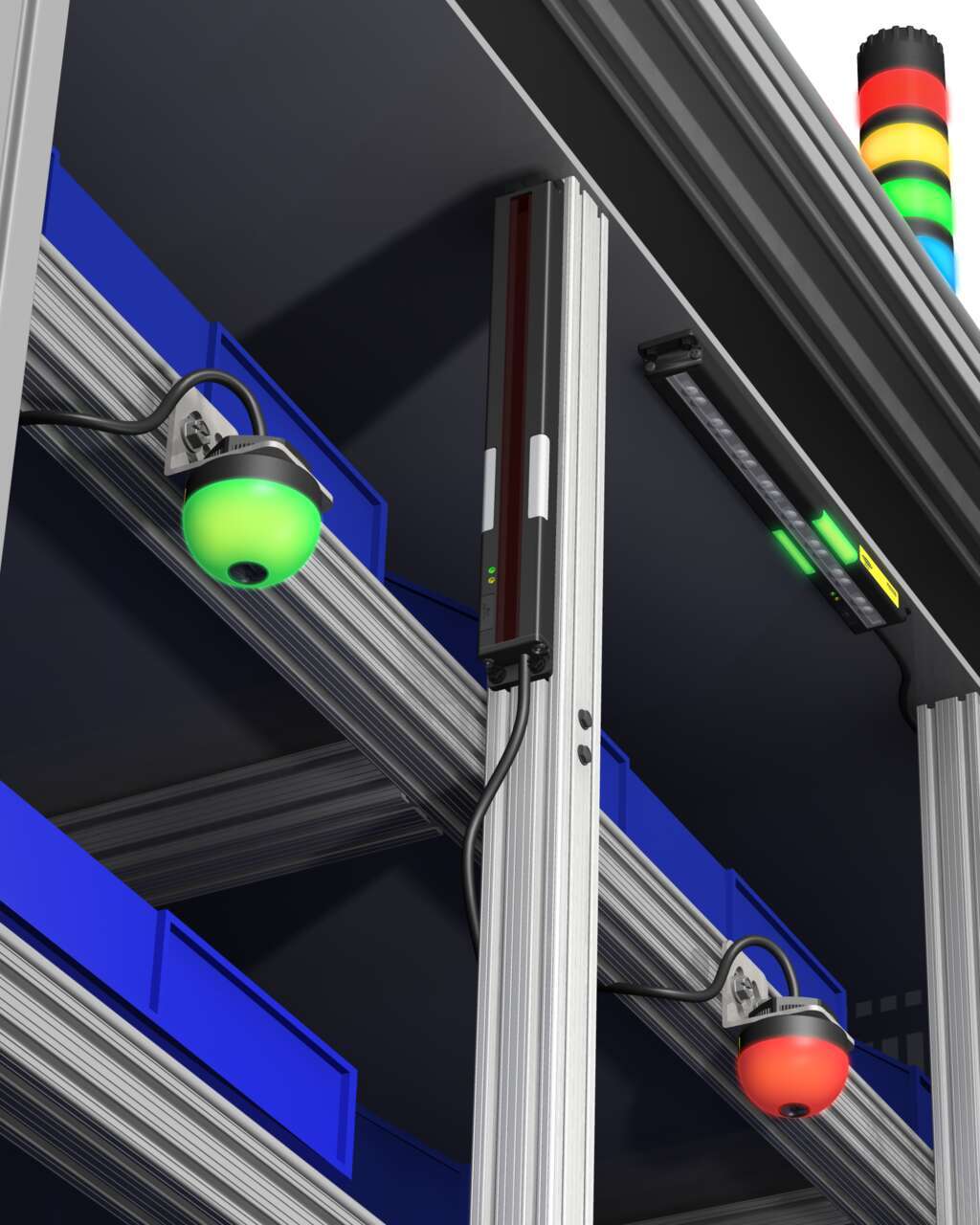

K50 指示灯、触控按钮和非接触式按钮

标准型与可编程型 K50 指示灯覆盖从基础状态指示到复杂视觉信号的多种应用需求。产品型号涵盖报警灯型、带声音提示型以及户外强光可视型,确保在室内外环境中都能清晰传达状态信息;同时具备 IP66/IP67/IP69K 防护等级,可在严苛工况下长期稳定运行。

标准型号支持快速部署,可以选择多达五种固定颜色,并有紧凑型、半球型、平面型等外壳形式,以及适用于危险区域和卫生环境的专用外壳。

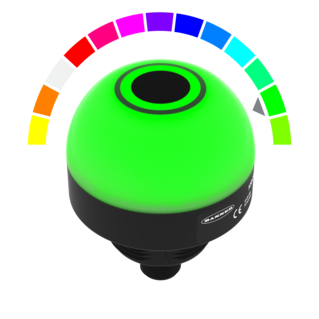

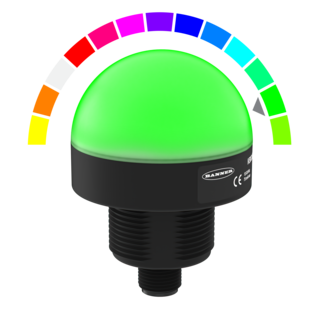

可编程型号则支持配置 RGB LED 响应,并可通过 IO-Link 或 Modbus 实现实时控制。借助免费的邦纳 Pro Editor 软件,可设置 14 种颜色和 11 种直观显示效果,也可通过通信协议进行动态控制。

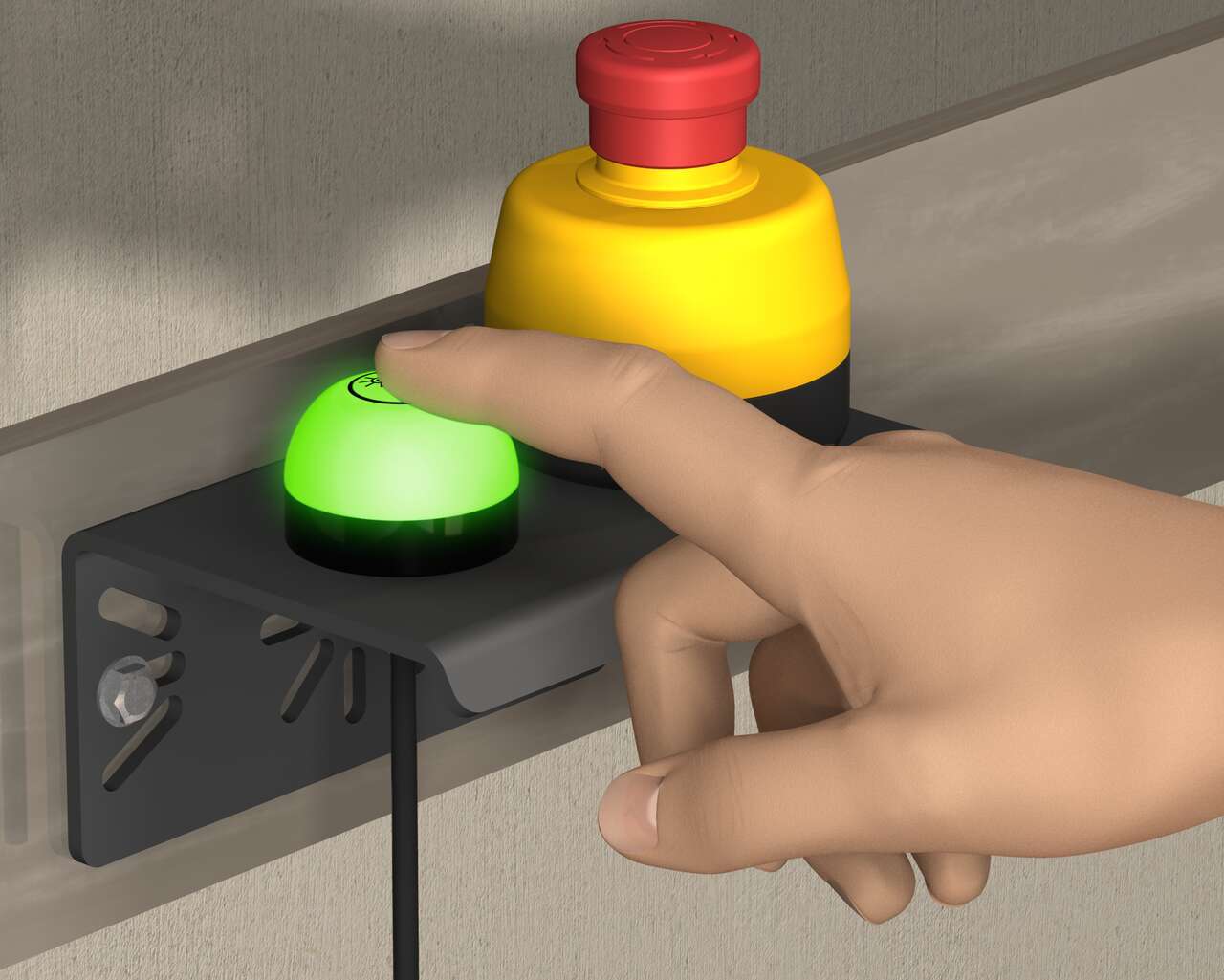

K50 触控按钮将先进的触控技术与清晰醒目的状态指示相结合,把过程信号转化为可交互的清晰反馈。所有型号均提供半球式和紧凑式外壳,在一个设备中整合锁定或瞬时功能,即可替代多个传统按钮,无需施加压力就能操作,从而简化面板设计,减轻操作压力并提升人体工学体验。

标准型号开箱即用,支持多达三种固定颜色,并可根据输入优先级进行选择。所有型号均达到 IP66/IP67/IP69K 防护等级,能够在严苛环境中稳定运行。

可编程型号在此基础上进一步扩展功能,支持触控响应参数配置、多种 I/O 模式,以及通过 IO-Link 或 Modbus 实现实时控制。颜色效果、直观显示以及通断延时均可通过免费的 Pro Editor 软件进行设置,也可通过通信协议动态控制。

此外,还提供带声音提示、集成显示功能以及采用 FDA 级材料外壳、适用于卫生环境的多种型号。

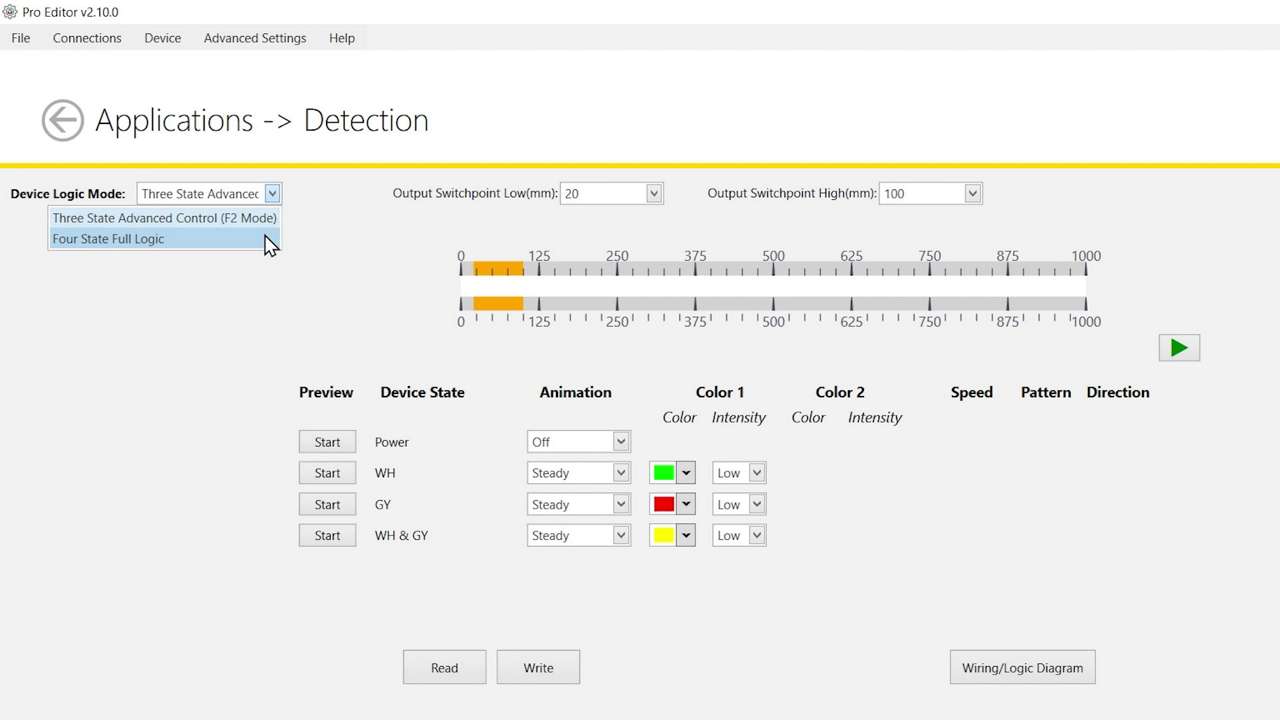

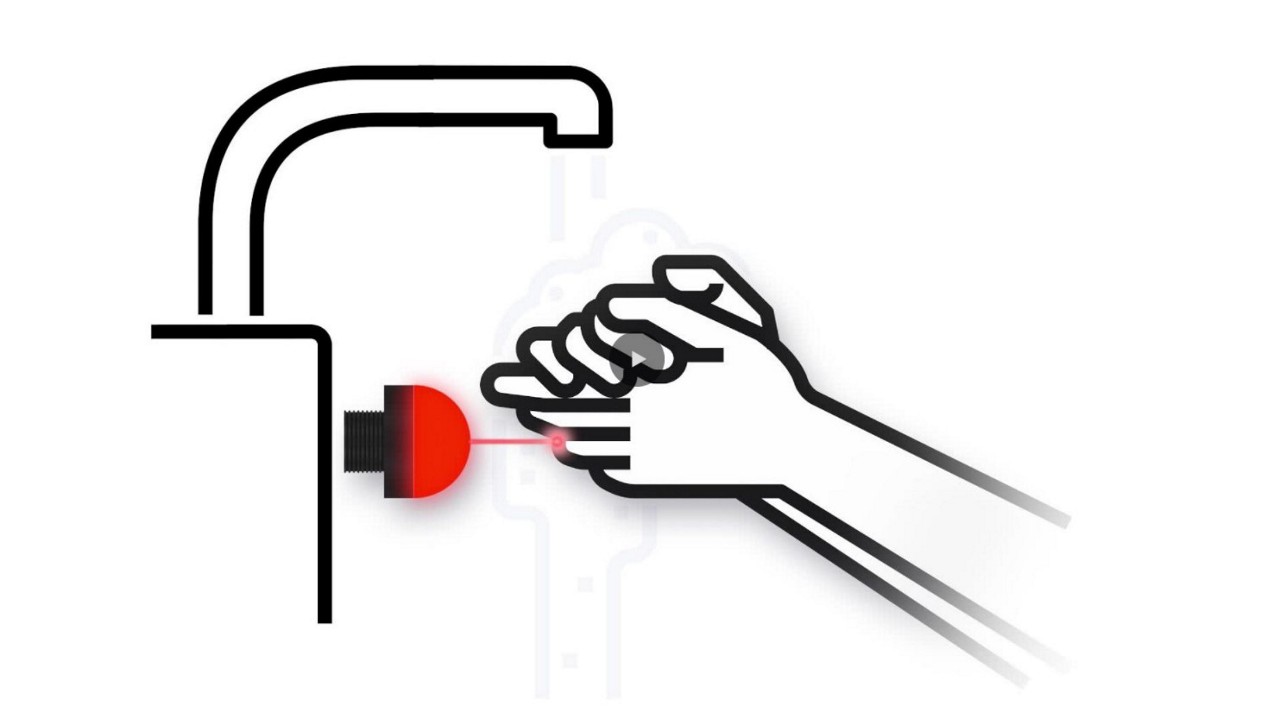

K50 非接触式按钮实现稳定可靠的无接触启动,并配备清晰醒目的状态指示,特别适用于高频操作场景,有助于减少接触点。光学感应距离可在 20 至 1000 毫米之间灵活设定,确保根据具体应用需求实现灵敏响应。支持 14 种颜色、11 种直观显示效果及通断延时设置。所有这些均可通过免费的 Pro Editor 软件进行配置,或通过 IO-Link 或者 Modbus 实现动态控制,从而提供直观明确的视觉反馈。由于支持邦纳 PICK-IQ 协议,因而在高密度系统中能够实现更快速的更新和实时反馈。

产品采用轻量化设计,在兼顾成本效益的同时,仍具备 IP66/IP67/IP69K 防护等级,适用于严苛工业环境。K50 非接触式按钮无机械运动部件,并内置对环境光、电磁干扰(EMI)和射频干扰(RFI)的抗扰能力,确保在严苛应用领域实现持久稳定的零接触控制。

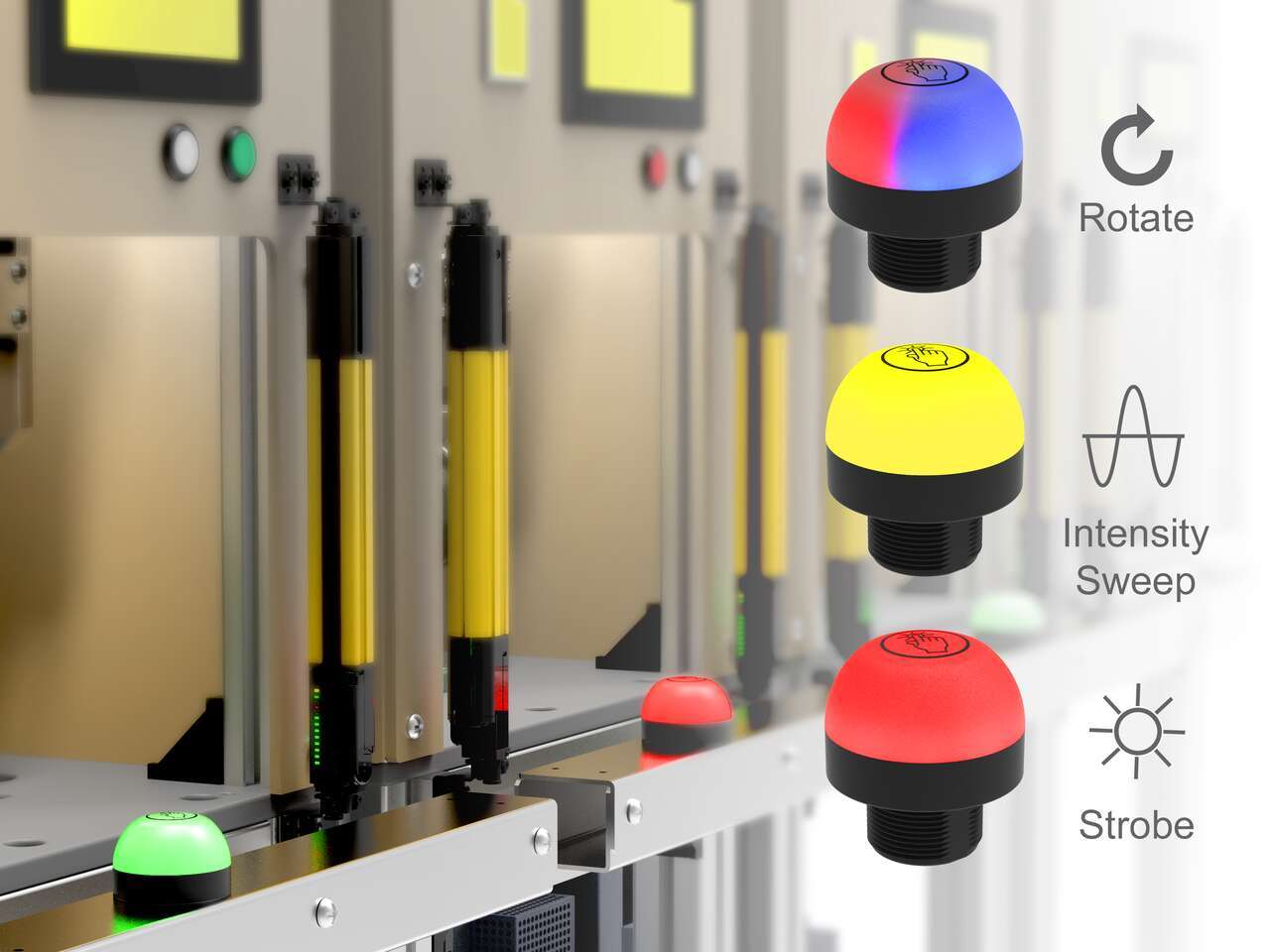

K50 可编程型号带来更高的灵活性与更丰富的表达方式,能够针对不同应用场景,以更具针对性的方式呈现设备状态与运行情况。用户既可通过免费的邦纳 Pro Editor 软件进行配置,也可借助 IO-Link 或 Modbus 实现实时控制。更丰富的颜色选择空间、LED 直观显示效果以及声音提示,使信号表达更加多样,能够清晰区分不同设备状态,引导操作人员及时响应,并确认工序进展。

LED 颜色可根据设备状态、输入条件或系统事件进行编程设定,从而为不同应用提供定制化的信号表达。设备默认提供七种预设颜色,无需额外配置即可使用;通过 Pro Editor、IO-Link 或 Modbus,可扩展至多达 14 种预定义颜色。每种颜色均可对应不同状态,无需增加硬件便可灵活调整信号机制。

直观显示效果可进行编程设定,通过动态变化来突出状态转变、引导注意力或强化状态识别,从而帮助操作人员更快速、更准确地作出响应。K50 支持多种直观显示形式,包括闪烁、旋转、强度渐变,以及追光或填充等灯段式显示效果。这些模式可与设备状态、定时器或操作输入联动,用于提示进度或在关键时刻强化提醒。

视听强度可根据不同环境条件或应用需求分别独立调节。LED 亮度支持低、中、高三档设置,在保证清晰可见的同时避免干扰。声音强度亦可根据安静或嘈杂环境进行调整。强度设置既可统一应用于全部状态,也可针对单一状态单独设定,并可通过输入信号、IO-Link 或 Modbus 进行切换(具体取决于型号)。所有调整均通过软件完成,无需进行任何物理改动。

具备声音输出功能的 K50 可编程设备支持多种音调类型,包括脉冲音、频闪音、警报音(siren)、起伏音(whoop)、摆动音(wobble)、连续音以及可选的旋律。每种音调在节奏与特征上均有明显区别,可用于将特定声音与不同事件、优先级或响应类型对应起来。音调可在软件中与具体状态进行映射,并通过输入信号或逻辑条件触发,同时可设置播放模式与持续时间。相关配置可通过 Pro Editor 软件完成,也可借助 IO-Link 或 Modbus 实现动态控制。

K50 I/O 触摸控制(带显示屏)配备紧凑型触摸感应界面,可在离散、脉冲或模拟应用中进行输出控制,并为操作员提供实时反馈,从而取代按钮、电位计和面板显示屏。离散型号可对用户输入和系统信号做出响应,在拣选应用中实现交互式控制。脉冲型号生成可选的 PWM 或 PFM 信号,用于调节邦纳 WLS15 Pro 指示灯等可变设备。模拟型号提供 0-10 V 或 4-20 mA 信号,用于平滑调光、速度控制或使用标准模拟量输入的其他应用。集成的 RGB LED 和 4 位 14 段显示屏使用色彩、动画和多达 16 个字符的滚动文本,来显示输出值、状态和设置,在设备上为操作员提供所需的信息。通过板载接口或Pro Editor软件即可简单配置,部署快捷、适配轻松,且不会增加复杂性。

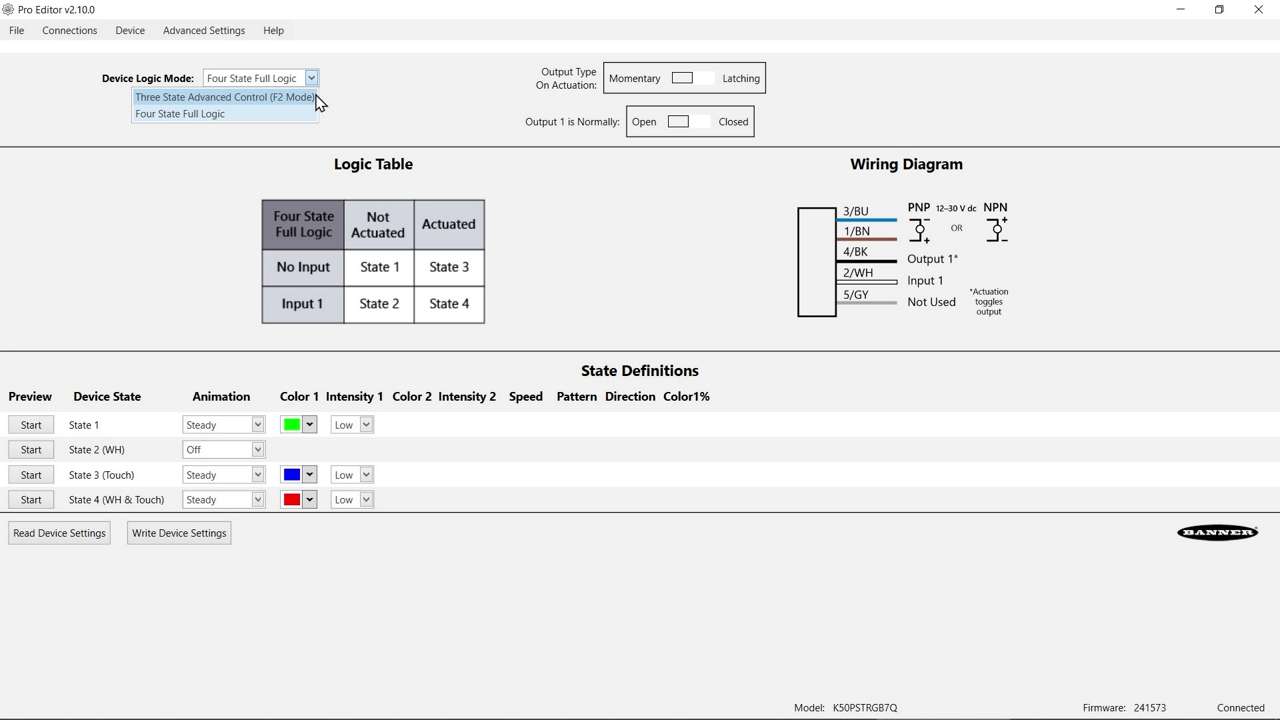

K50 可编程设备可能够根据不同输入进行灵活配置,同时控制自身的显示效果及其向其他设备输出的控制信号。输出行为可结合设备在系统中的角色进行定制,无论用于状态指示、事件确认,还是驱动下游动作,都能匹配相应需求。可配置模式包括瞬时或锁存输出、常开或常闭状态,以及可调的通断延时。配备模拟或 PWM/PFM 输出的型号,可反映系统数值,或根据逻辑条件或触控输入实现动态响应。相关逻辑与控制参数可通过免费的邦纳 Pro Editor 软件进行设置,也可借助 IO-Link 或 Modbus 实现实时控制。功能选项涵盖从基础通断控制到四态逻辑,每种状态均可定义独立的输出行为与外观表现。

K50 危险区域型号已通过相关认证,适用于需符合全球危险场所分类标准的应用环境,包括基于 Zone 和 Division 两种体系的分类要求。针对对清晰度与一致性要求极高的场景,这些型号在密封、抗冲击外壳(IP67/IP69K 防护等级)中提供多达三种可变状态颜色。经认证的防护方式包括本安型设计、无火花设计以及密封式构造,以防止可燃气体或粉尘被点燃。

FDA 级型号采用符合规范的材料制造,并配有激光标识标签,可承受频繁的高压冲洗,又不会导致标签损坏或误触发。其全密封结构达到 IP67/IP68/IP69K 防护等级,可抵御水雾、泡沫及油脂侵入,在反复清洁条件下仍能保持稳定可靠的信号与操作性能。该系列可提供指示灯或触控按钮形式,适用于对卫生要求严苛的生产环境,实现清晰传达与持续稳定运行。

Use RSio to create a complete safety solution for robotic palletizing cells that takes advantage of hybrid I/O and In-Series Diagnostics (ISD).

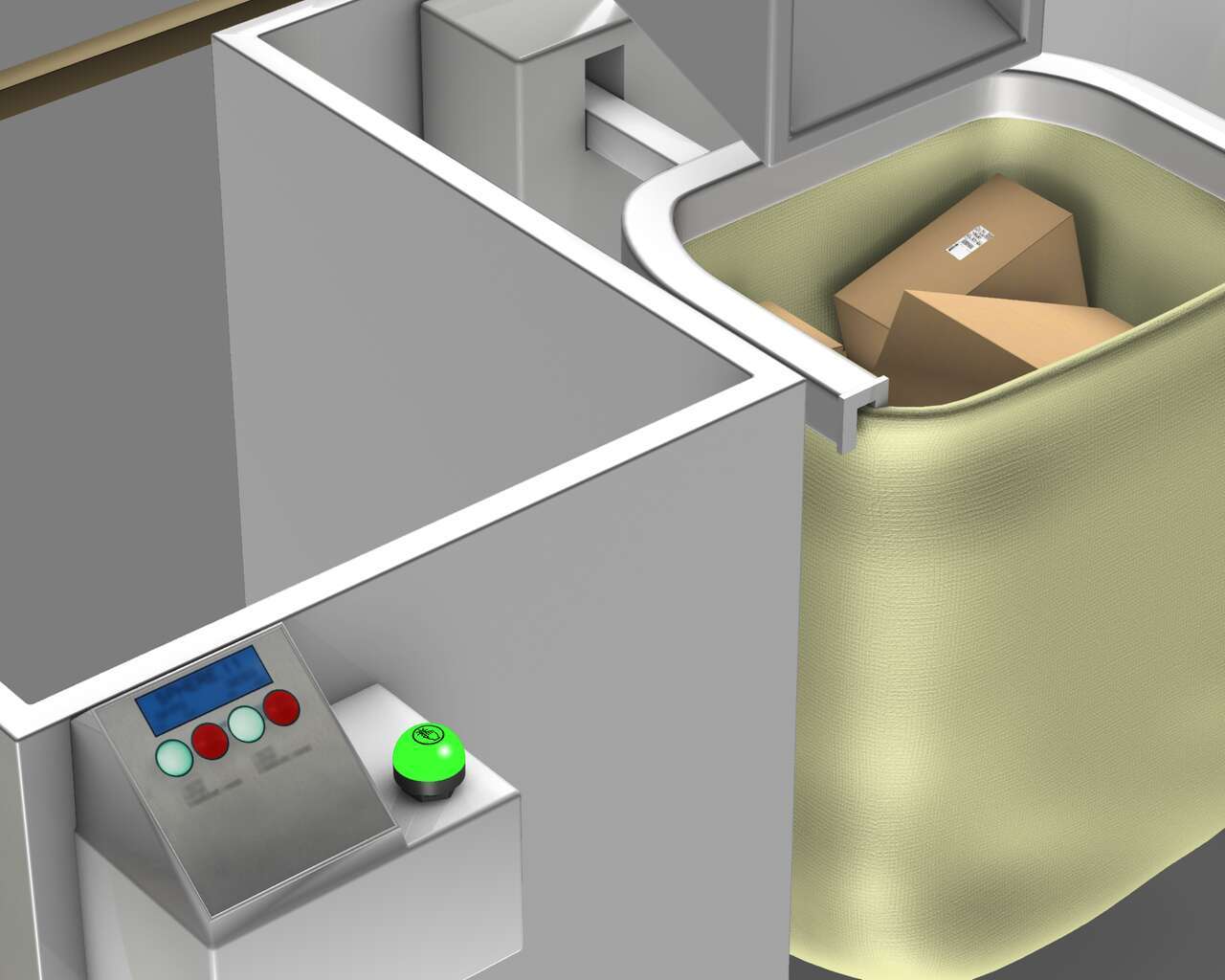

一名负责安装行李处理传送带系统的经理想用不同的颜色和直观效果来指示启动、卡塞和复位状态。

该客户需要一种这样的解决方案:通过将指示灯安装在叉车仪表板上,来加快叉车操作员的响应速度,并且也要便于叉车操作员确认请求,避免有多个操作员重复提供零部件。

装卸区的车辆检测非常复杂,因为检测解决方案暴露于外界环境,需要识别各种各样的表面。利用坚固耐用的超声波传感器,可以准确检测各种材料运载车辆的表面。再配上明亮的 LED 指示灯,就能为操作员提供明确无误的指导。

配备 IO-Link 通信功能的 K50 Pro 触摸按钮可在工人视线范围内显示产距时间,以保持正常的装配进度,实现生产目标。

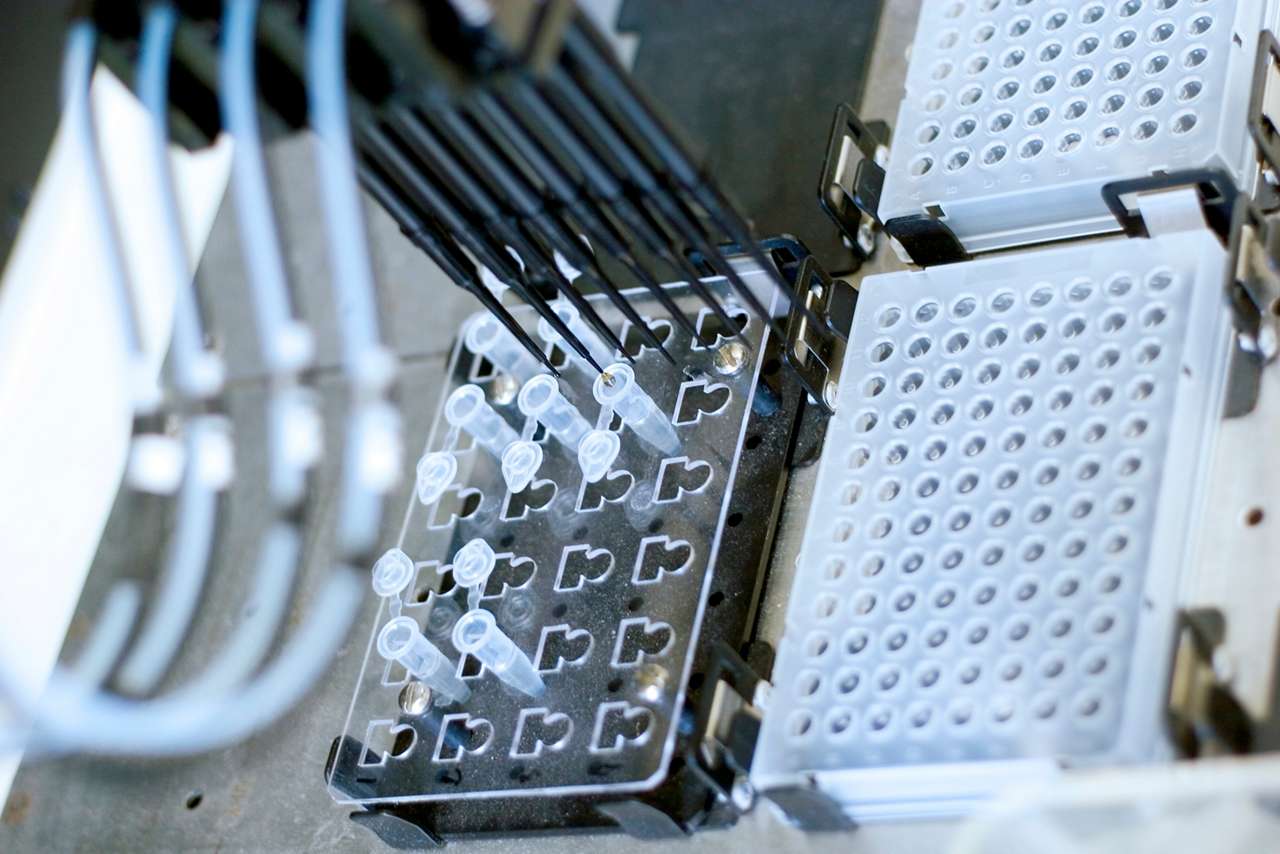

临床实验室需要快速处理样品以保持较高吞吐量,试验过程中的任何滞后都会破坏工作流程。使用 LED 照明灯(例如 K50L2)指示机器状态,有助于实验室操作员及时修复错误、处理样品和收集结果。

对于烘焙而言,创意、精度和注重细节缺一不可。Wilkinson烘焙公司往其中加入了技术创新。Wilkinson面包是一家独立的全自动烘焙公司。这种独特的机器将技术与传统相结合,以每小时40个面包的速度,将简单的原料转化为面包店里新鲜出炉的面包。

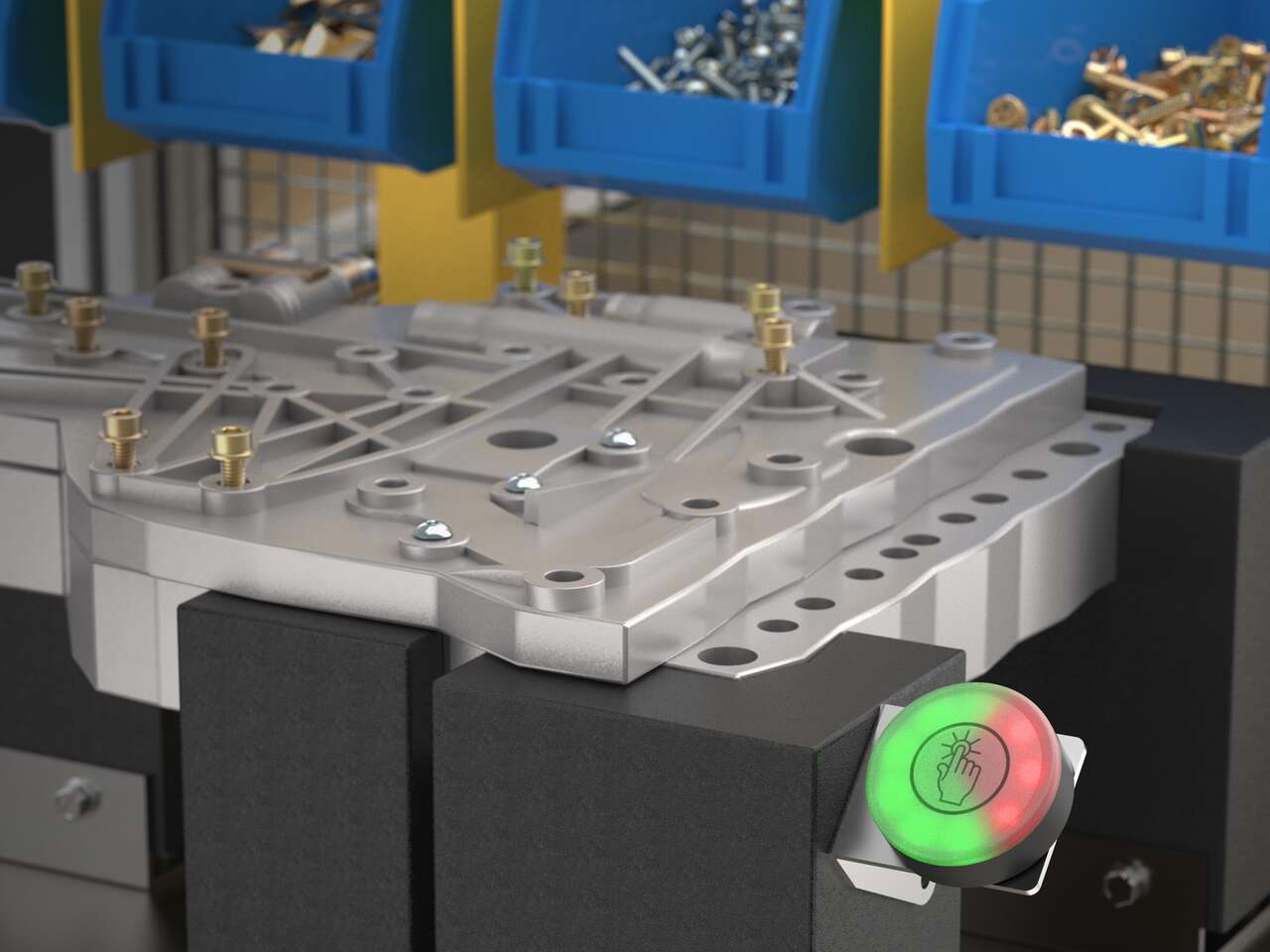

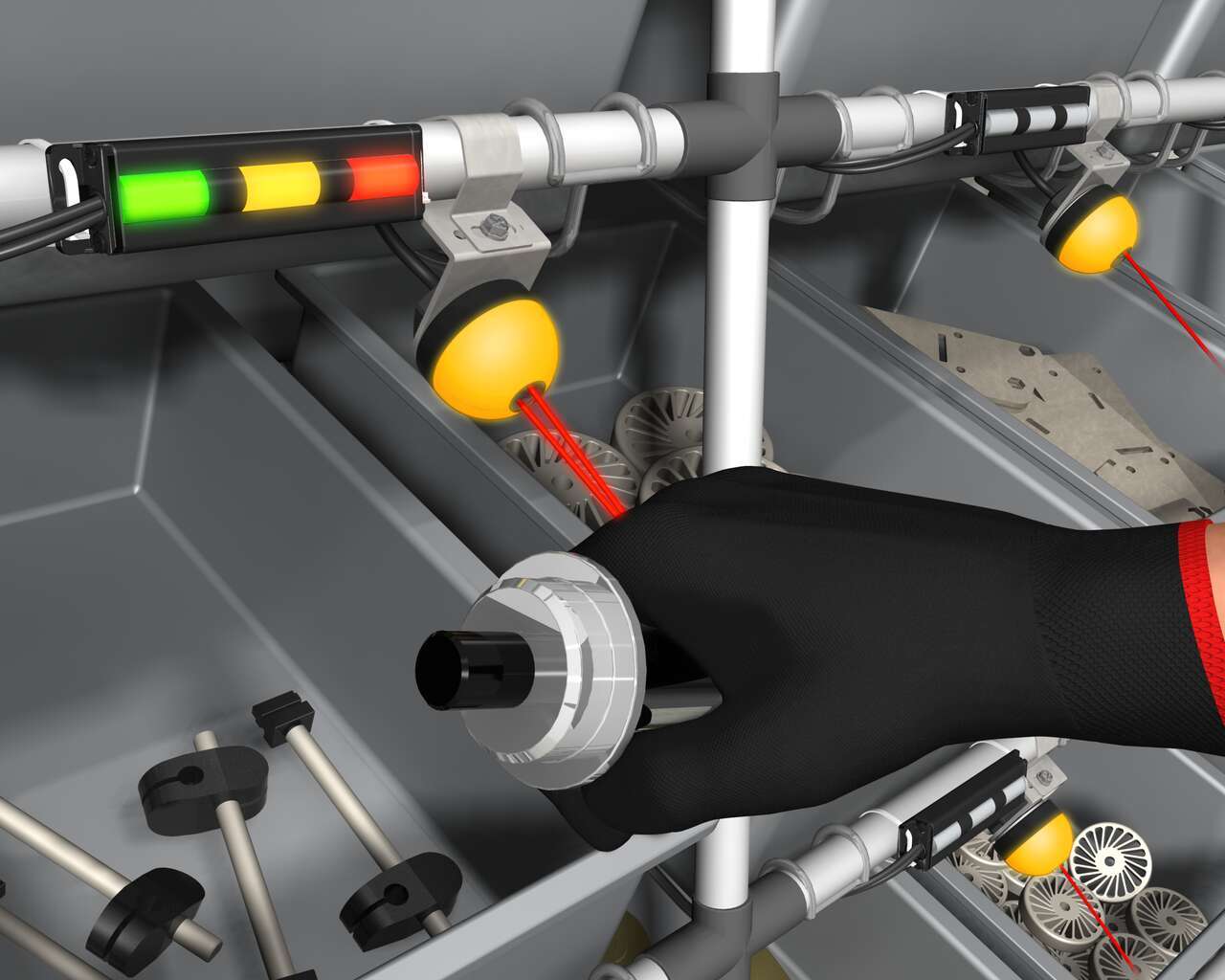

客户生产用于汽车行业的动力传动系统和动力系统。由于变速箱阀体组装出错,该公司遭遇了生产损失。客户想要一种能够减少错误并改进组装过程的系统。

K50L 50 毫米圆顶指示灯非常适合用于指示自动穿梭巴士的状态。这些巴士在户外环境下从事短途通勤,巴士技术暴露于各种各样的天气条件下。K50L 指示灯非常坚固,其防护等级为 IP67 和 IP69K,在恶劣环境下也能防止进水。

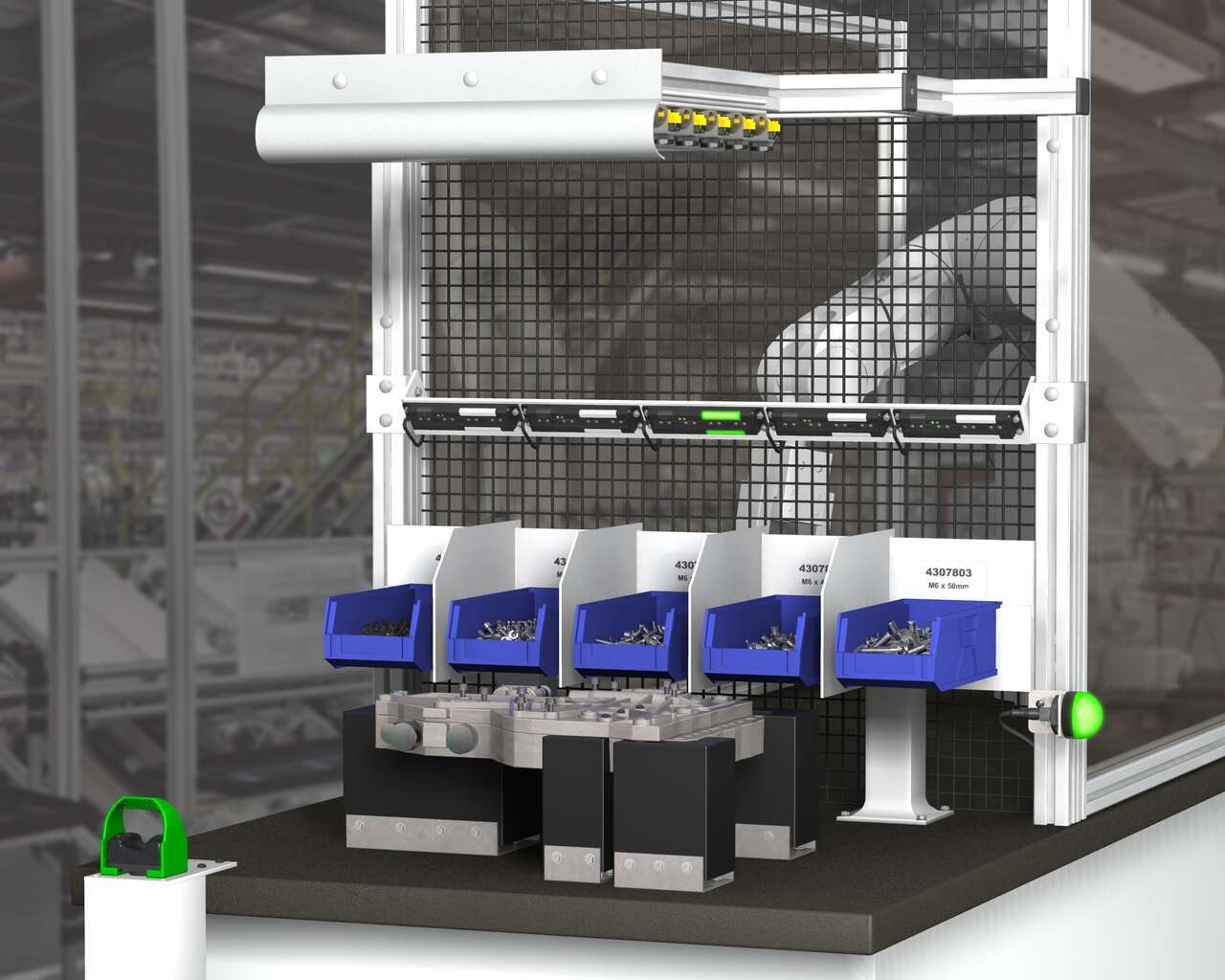

一家领先的机器制造商要建造工作站,旨在实现准确、及时且经济高效的电池单元装配。工作站的一个增值组件是要负责三项工作的操作员指引设备:支持启动和停止装配流程,指示要拣货和安装的部件,以及在发生紧急情况时完全停止生产线操作。由于OEM自己建造和安装这些设备的代价极其高昂,因此他们转向邦纳求助,希望能为他们推出一款全面的解决方案。为了满足其客户(主要二级电池供应商)的时间要求,OEM必须在八周内落实该解决方案。

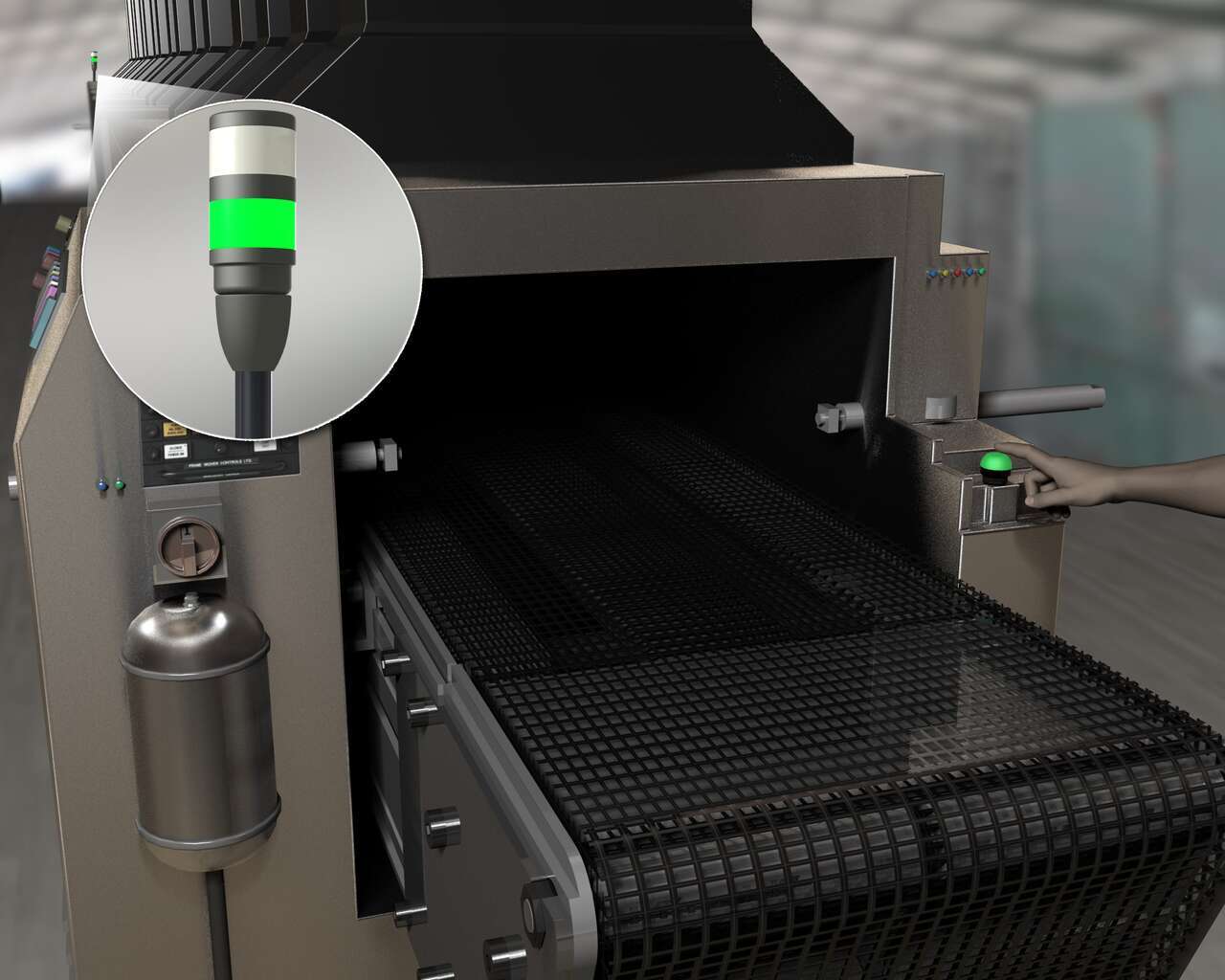

随着越来越多的组件行经烤箱,与要卸货的物品流动保持同步变得越来越难。分拣区逐渐变得拥堵。物品很容易输送到错误的方向,甚至损坏。暂停零部件,留有助于卸货操作员纠正错误和清理拾取站。不过,卸货和装货区之间的距离以及周围机器的环境干扰让操作员之间的通信变得复杂。

车道中的每个生产操作员配备了无线节点和K50 EZ-LIGHT。在每个叉车上则安装另一个节点和EZ-LIGHT。当生产操作员需要补给时,操作员按下EZ-LIGHT上的按钮,灯的颜色将从绿色变成红色。同时,叉车司机的灯由绿色变为红色,以指示操作员需要零部件。

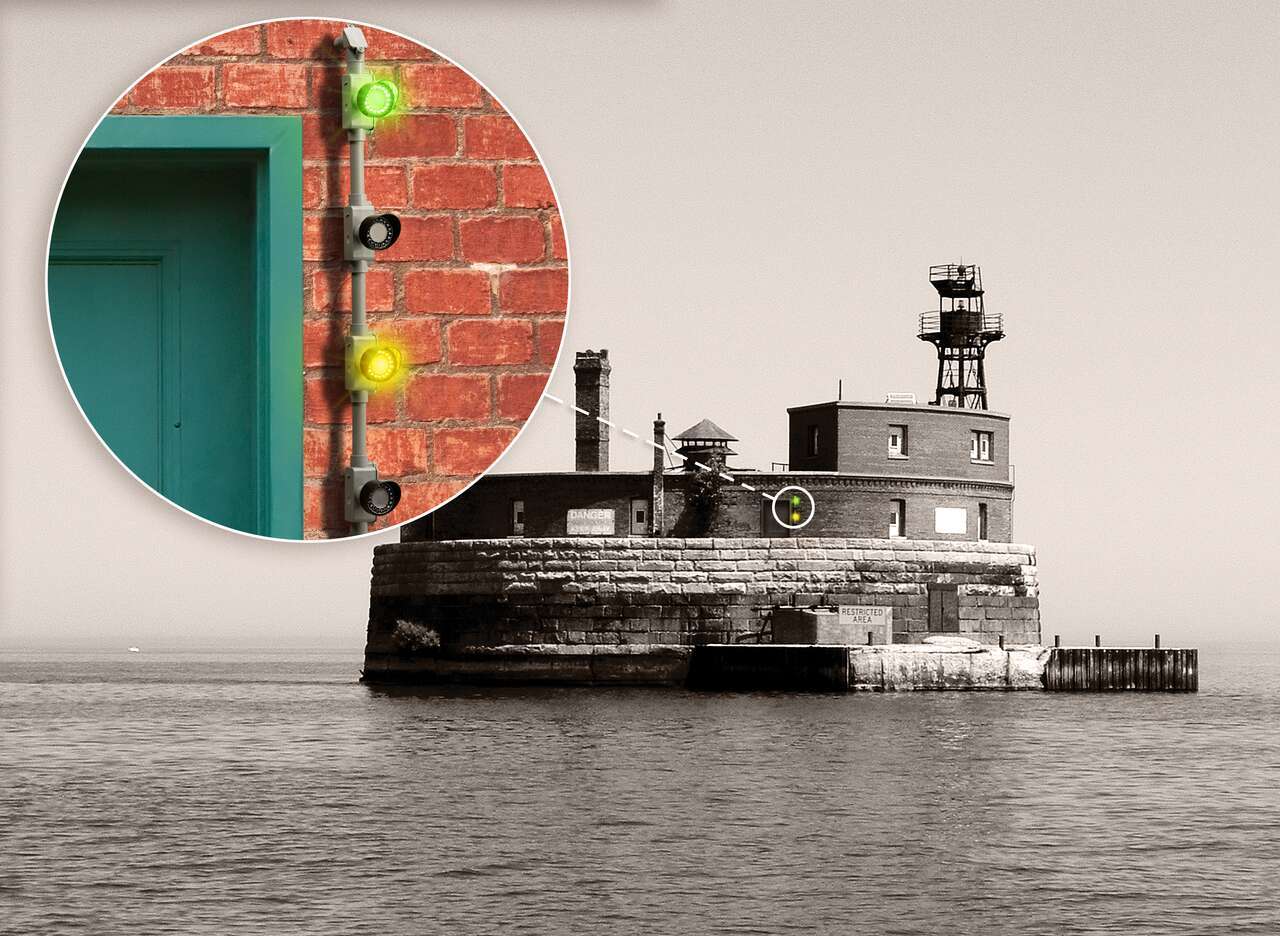

EZ-LIGHT日光可见型指示灯能够产生强烈的光线,18个LED灯可以一起激活,或以6个为一组共分为3组来控制光线强度,非常适合需要在户外环境下清晰通信的应用。选配的防晒护板增加了它们的可见性,即便在阳光高强度照射的环境下也很有效。

用于检测一条较长的,需要监控多个区域的较长灌瓶作业线上盛装透明液体的透明瓶子的传感器解决方案。

当窗户位于机柜正后面时,格外明亮、持久的LED指示灯可以全天候提供高亮度的指示。邦纳EZ-LIGHT K50 灯塔指示灯非常适合许多状态指示应用,特别是在这个机柜中,因为即使在白天指示灯也清晰可见,并且高能效的LED灯非常耐用。

视觉指示是一种简单、有效的状态沟通方式,可使设备有效地运行并提高生产力。明亮的指示灯在白天格外显眼,能够指示吊具扭锁到操作舱的情况,以确保安全起吊。Beacon指示灯具有强烈的光输出水平,而且非常坚固耐用,使的其成为了户外指示应用的理想之选。

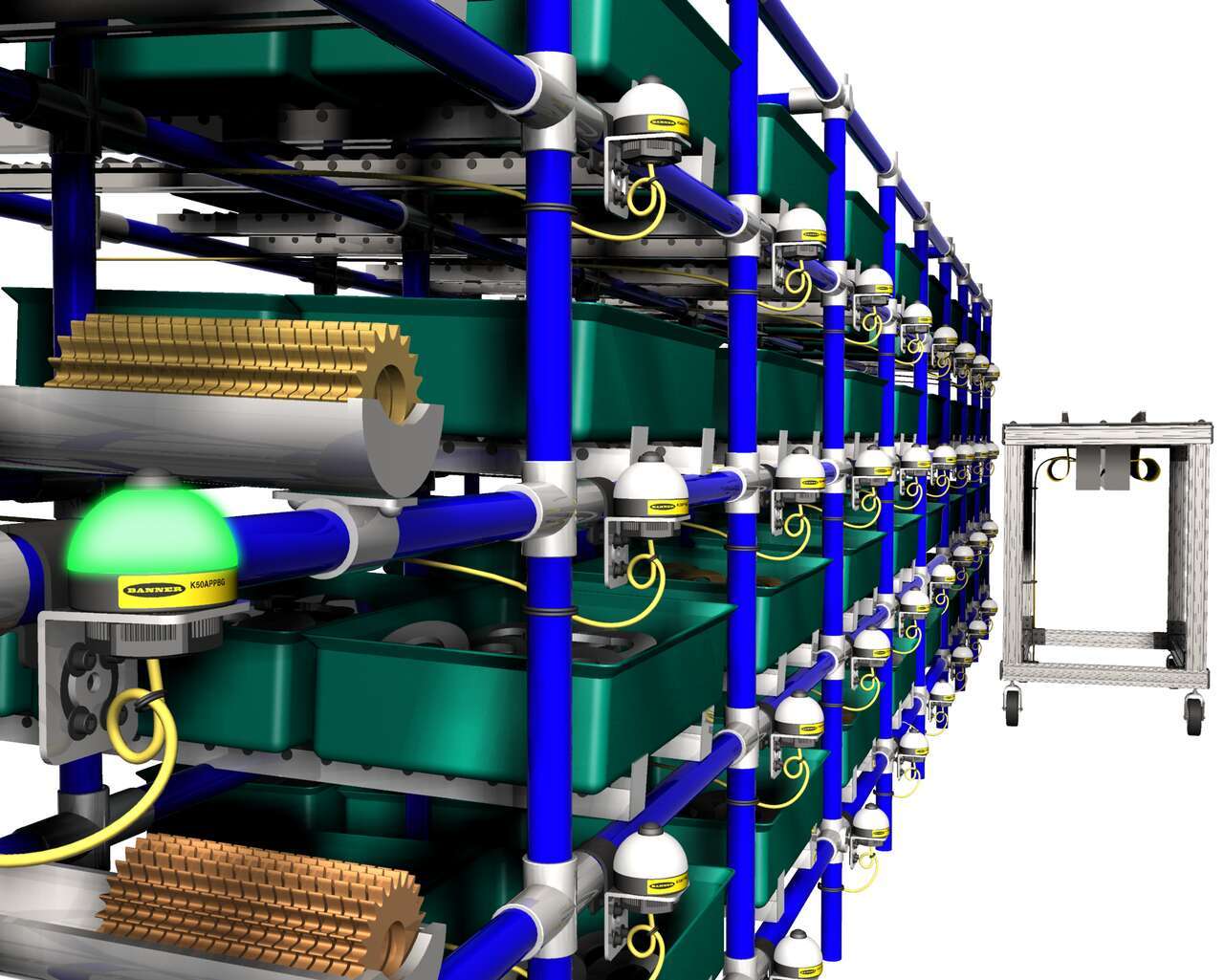

邦纳无线解决方案是一种优化库存、减少错误和尽量减少浪费的方案。每个具有I/O映射的Sure Cross节点可以配备多达六个EZ-LIGHT操作指示灯。Sure Cross网关位于中心位置,便于维护人员和管理人员监控整个场所的部件消耗情况。

EZ-LIGHT K50传感器在料盒上方亮起,以向装配工人显示要拣选的部件。如果装配工人伸入错误的料盒,则该料盒的EZ-LIGHT K50传感器将亮起指定的警告颜色(在本例中为红色)以指示发生错误。

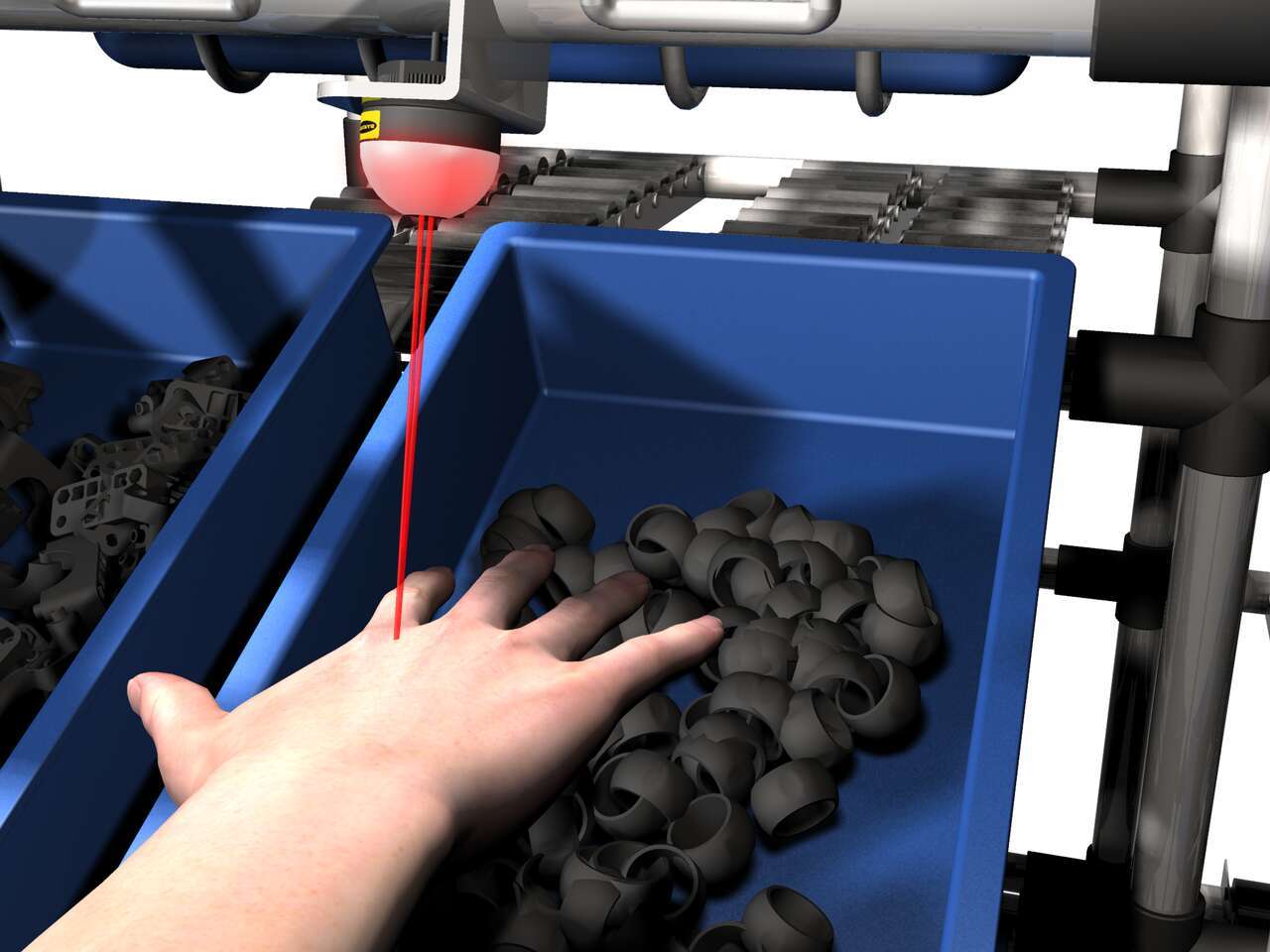

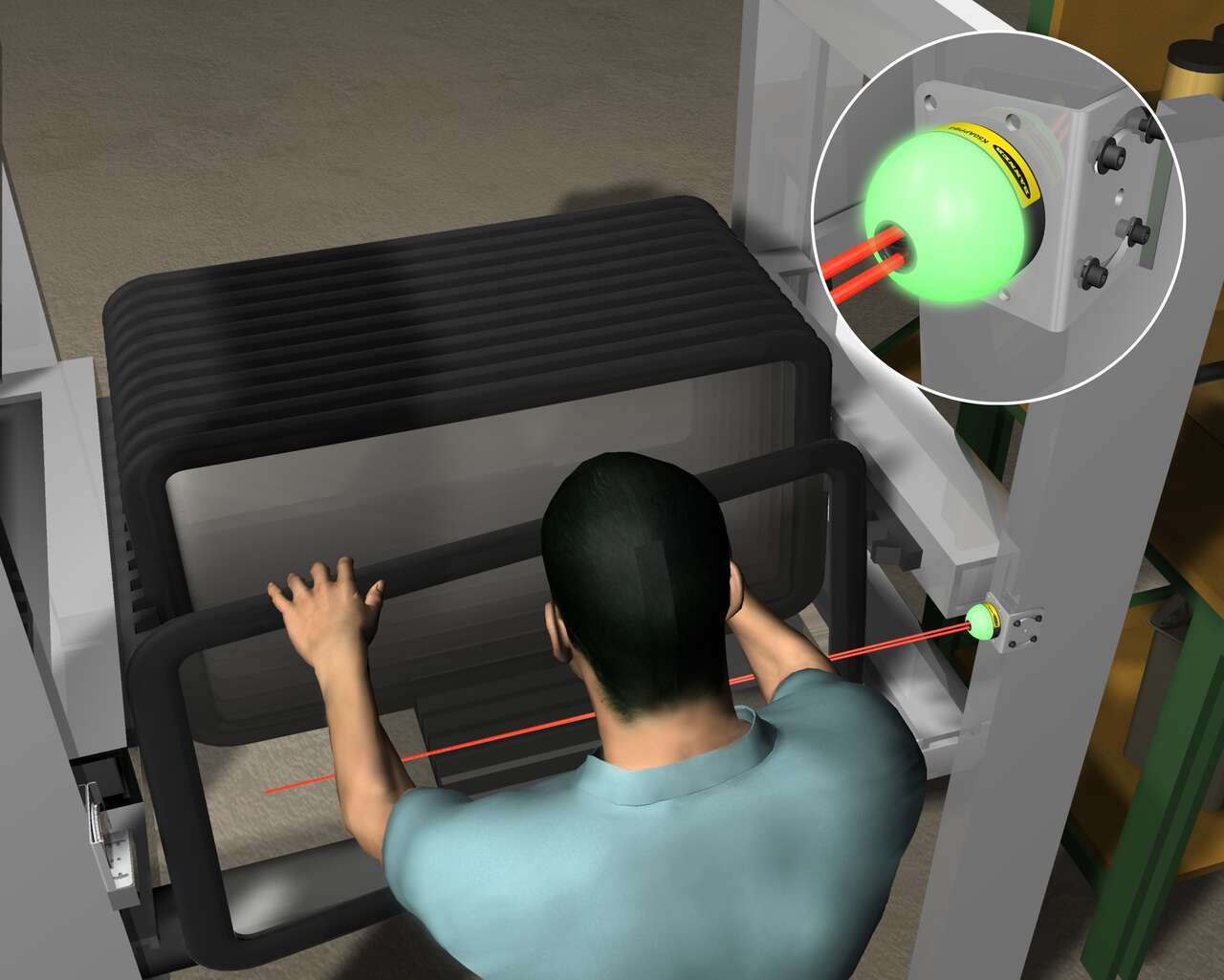

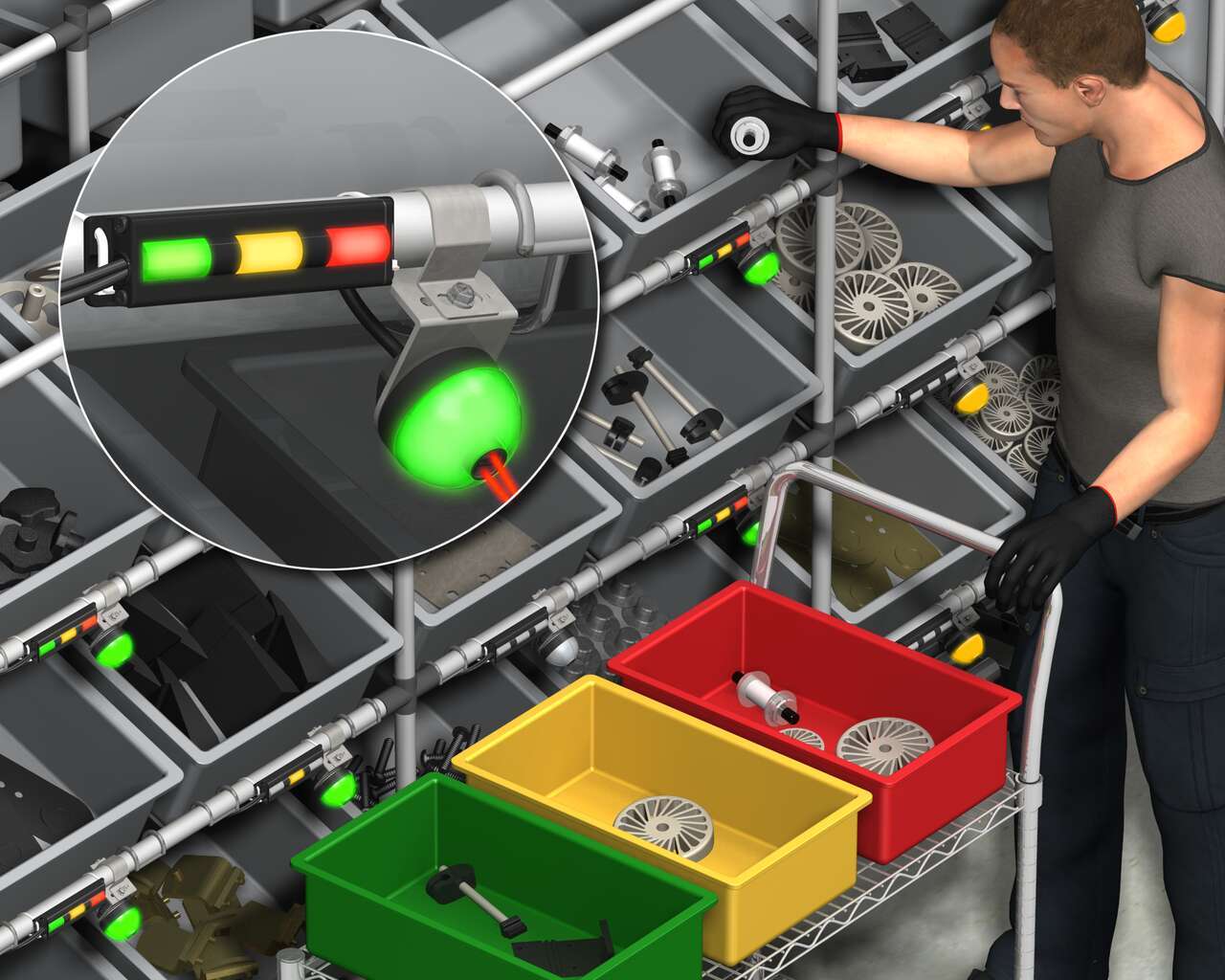

邦纳K50光电拾取指示灯是一种小巧、独立的三色指示灯,配备有集成的传感器。绿色通常指明要拣货的部件,当内部传感器检测到手时,指示灯会变为黄色,从而确认任务完成。可选的第三个消息将显示红色,以表示拣货错误。

在糖果分销商的按订单拣货操作中,料盒配备了EZ-LIGHT K50传感器,它会连接到相应的流程控制器。根据订单,K50将亮起以显示要拾取的物品。工人将手放入料盒时,指示灯会检测手是否出现,然后控制器会触发要拣货的下一个料盒上的K50。

多种技术和解决方案可用于料盒拣货应用以防止流程出错。系统给使用集成的工作灯来提示操作员进行部件选择,然后会使用一组位于料盒前部的可见红色或红外感应光束,从而可靠地感应部件被拾取。

采用反射板式的EZ-LIGHT K50传感器可指明装配顺序中的下一个部件是天窗。操作员从宽箱中选择天窗时,K50会检测到拾取动作。

部件货架上的部件按钮EZ-LIGHT K50按灯拣货传感器会点亮,用以指明要拣货的部件。进行部件拣货后,工人可按指示灯上的按钮,从而验证拣货完成。

在组装应用中,邦纳K50系列单点拾取指示灯传感器是一种简单易用的防错解决方案。在此应用中,当作业输入信号处于激活状态时作业指示灯显示绿色,以指示下次要从中拣货的正确料盒。如果检测到装配工人的手,则会启动状态输出变化,作业指示灯亮红色。下一个拣货位置上方的作业指示灯则亮绿色。

K50 Pro 可编程式触摸按钮和 Pro Editor 软件提供独特指示,适用于多种机器状态指示和现场定制。多色和直观显示效果有助于快速识别工作单元中的错误。

邦纳的定区域式K50指示灯可以检测戴着手套的手,当操作员在配料过程中拾取正确的零件时做检测。之后,K50指示灯的逻辑功能通过将指示灯的颜色由绿变黄(可以根据制造商的偏好选择其他颜色),来告知操作员拣选了正确的物体。K50检测黑色手套的能力对于工人通常佩戴黑色手套的精益制造流程格外重要。

为了正确识别和利用视觉管理,当袋子装满时会触发传感器,然后将信号发送到K50触摸按钮灯亮红灯,由此指示手提箱装满。K50触摸按钮灯可以直观地示意操作员需要移开袋子并更换空袋子。要显示袋子已准备好接收更多的包装,操作员按下K50触摸按钮灯,颜色变回绿色,以此指示袋子准备好接收更多的包装。

急停按钮配备一体式外壳,当它与K50 Touch指示灯结合使用时,能够在紧急情况下提供简单的状态指示。

邦纳的带报警塔灯TL50配备有多个不同颜色的高品质LED灯,与K50 Touch和PM8无线系统结合使用,可提高物料呼叫过程的效率。开始之前,先将邦纳的K50人机触摸按钮安装在监督站并根据相应的PML8无线节点进行编号,而PML8无线节点分别随可发声塔灯安装在各工作站。

在严酷的冲洗环境下,提醒操作员食品加工生产线上检重站的故障状态。

纸板商品印刷机由于无法跟踪机器操作员的效率和性能,而无法按标准生产速度进行测量。

在安装EZ-LIGHT K50L指示灯之前,操作员要在机器上放置部件,然后离开工作区域查看塔灯,以确定此部件是否正确装载。如果没有,操作员必须在启动机器对该部件执行操作之前重复进行设置和检查过程。由于K50L安装在工作台内,所以使用简单的Y接头,操作员即可立即分辨出是否已正确放置部件。

实现洗车场内部明亮指示的传感器解决方案,从而显示洗车周期各阶段。

当零部件供应量不足时,组装人员向左按下EZ-LIGHT K50按钮,该按钮用作呼叫按钮,示意物料员供应更多的零部件。将K50灯向右按下则用作零部件拾取指示灯。

在使用Sure Cross无线网络时,可以将FlexPower节点部署在每个储罐上,无需为电源或I/O数据传输敷设电缆。邦纳拥有独特的电源管理功能,这使得配备超声波模拟电平传感器的节点可以在单个DX81电池电源上运行多年。DX80 FlexPower节点在单一封装中提供了离散和模拟I/O组合,无需耗费时间手动采集数据。

由邦纳TL70无线模块化塔灯和K50触摸按钮组成的系统可提供一种高效、轻松的方式,以便向叉车司机传达调用更多部件的指示。当工作站的纸箱快用完时,操作员可触摸采用人体工程学设计的K50触摸按钮,然后所连接的TL70无线塔灯上的状态指示就会变成红色。

We noticed you didn’t finish your online checkout. We're dedicated to providing the best shopping experience possible and would love to hear if you faced any challenges. Let us know how we can make your experience even better.

观看本视频,了解 K50 可编程触摸按钮的功能和优点。

观看本视频,了解 K50 可编程非接触式按钮的功能和优点。

观看本视频,了解 K50 可编程指示灯的功能和优点。

Watch this video to learn about the K50 Pro Select Touch Button 3-State Mode.

Watch this video to learn about the K50 Pro Select Optical Touch Button 4-State Detection Mode.

Watch this video to learn how to use the Pulse Control feature of the K50 Pro Select Indicators.

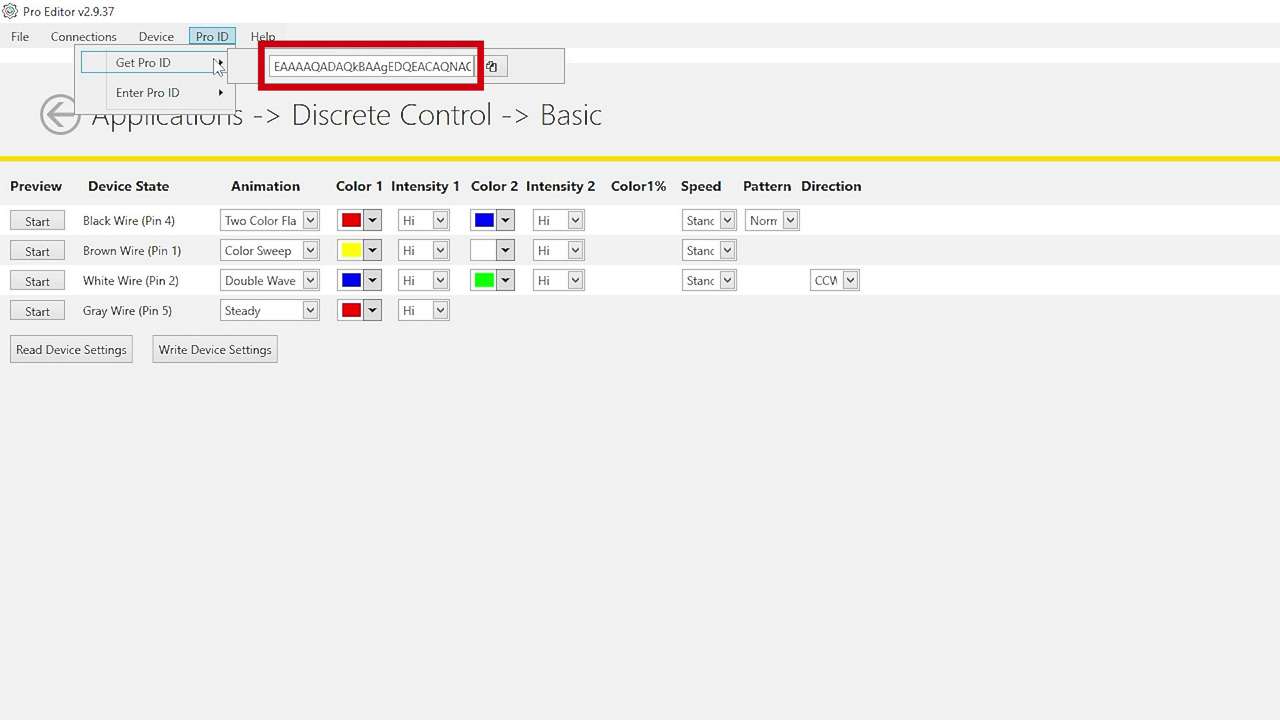

Watch this brief how-to video to see how Banner’s Pro ID feature and Pro Editor software quickly and easily copy configurations to Pro Select lighting products.

这段视频介绍了对邦纳 K50 Pro 触摸按钮特定型号中的声音警报进行编程的基础知识。

这段视频介绍了邦纳 K50 Pro 触摸按钮 4 态模式的基本知识。

这段视频介绍了邦纳 K50 Pro 触摸按钮 3 态模式的基本知识。

邦纳 Pro 系列可设定多色 LED 设备,为动态的机器状态、操作员交互和流程状态的高级指示创造了无限可能。观看视频,了解邦纳 Pro 指示灯胜过传统工厂指示灯之处。

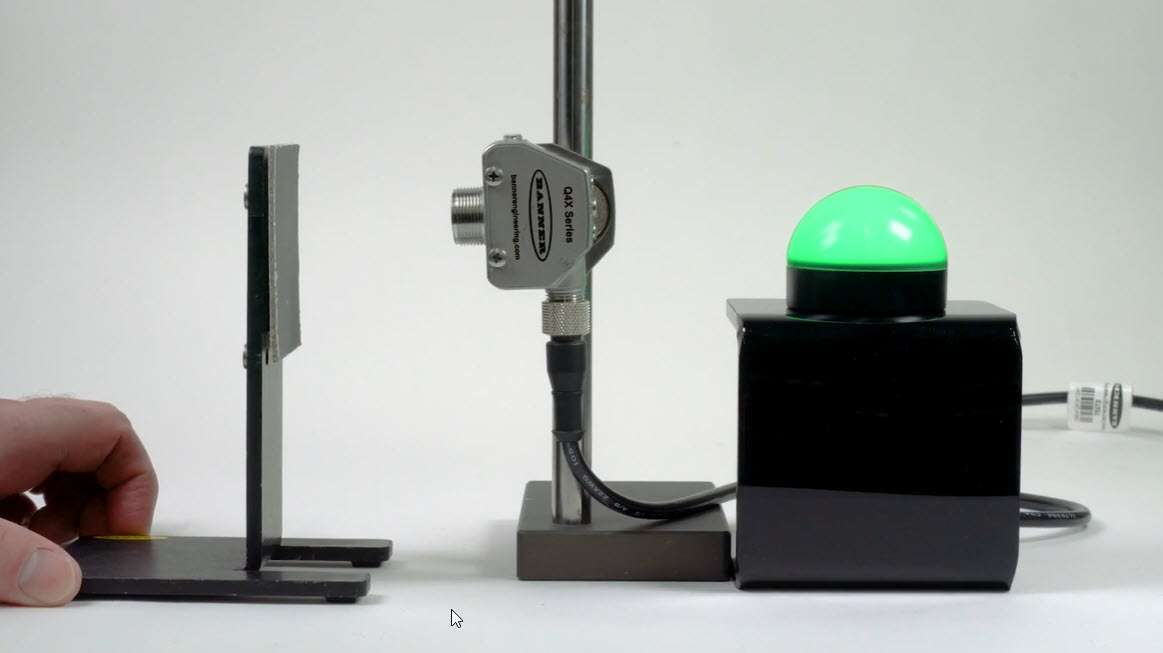

K50 Pro 光学指示器的非接触式应用

观看工人如何使用 K50 Optical 通过非接触式激活呼叫操作员。

观看 K50 Pro Optical 如何协助进行非接触式洗手。

邦纳提供全面的触摸按钮产品组合,无论是最简单的还是最先进的触摸要求,它都能满足。观看视频,进一步了解我们的触摸和指示功能。

指示灯是机器的可视化语言。然而,传统指示器功能有限。观看视频,了解可编程 RGB 指示如何进行清晰通信、简化供应链,以及如何快速创建与流程相匹配的定制指示。

即使在脏乱的恶劣环境下,邦纳的第二代触摸按钮也能对触摸做出准确的响应。耐化学性的聚碳酸酯外壳即使直接喷洗也不会损坏。

邦纳推出第二代 K50 和 K30 指示灯,带给您更多状态指示选择,同时简化了布线和库存管理。坚固耐用,一个型号有七种颜色可可以选择。

了解如何使用 Pro Editor 配置 K50 Pro 触摸按钮。

这段视频介绍了邦纳 K50 Pro 系列指示器的基本设置方法。

Our application engineers are here to help with expert guidance and support. Send us your inquiry, and we’ll get back to you as soon as possible. We’re here to make sure you get the answers you need.