后道饮料包装解决方案

-

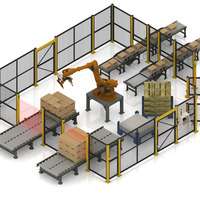

机器人码垛机安全防护

机器人码垛机安全防护

邦纳的XS26-2是一款编程环境直观并且灵活易用的安全控制器,它能够处理当前的机器加工过程,还能灵活增加多达8个I/O扩展模块,从而适应机器自动化发展或变化。支持各种安全设备,允许在极短时间内下载并配置复杂的应用程序,从而高效调试机器。

-

码垛机和拉伸型缠绕包装机安全防护

码垛机和拉伸型缠绕包装机安全防护

实践证明,码垛机和拉伸型缠绕包装机周围区域的安全防护非常难,因为它会涉及到多种危险。可扩展的安全控制器能够帮助管理与码垛机和拉伸型缠绕包装机相关的危险,同时确保有效的安全防护过程。

-

读取多个一维和二维条码

读取多个一维和二维条码

条码的位置可以随着传送带上每个箱子的位置变化而变化,箱子的高度也可以变化。ABR 7000 读码器能够在同一次检测中解码大范围内的多个一维和二维条码,且不受位置或方向的影响。

-

通过视觉指示传达安全状况

通过视觉指示传达安全状况

为了在饮料行业保持高效的生产线,立即传达任何安全问题至关重要。利用视觉和听觉指示来识别安全问题有助于工作人员快速找到并纠正错误,及时将系统恢复到正常运行状态。